Prestige SOLO 110 and EXCELLENCE

Natural to LP Conversion

3

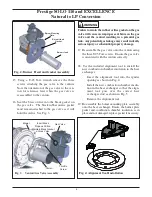

15. Using a T-25 Torx wrench remove the three

screws attaching the gas valve to the venturi.

Note the orientation of the gas valve to the ven-

turi for reference later when the gas valve is

reassembled to the venturi.

16. Seat the brass orifice into the black gasket on

the gas valve. The black rubber orifice gasket

must remain attached to the gas valve as it will

hold the orifice. See Fig. 3.

Failure to retain the rubber orifice gasket on the gas

valve will cause an improper seal between the gas

valve and the venturi resulting in a potential gas

leak. Any potential gas leakage may result in death,

serious injury or substantial property damage.

17. Reassemble the gas valve onto the venturi using

the three T-25 Torx screws. Ensure the gas valve

is orientated with the venturi correctly.

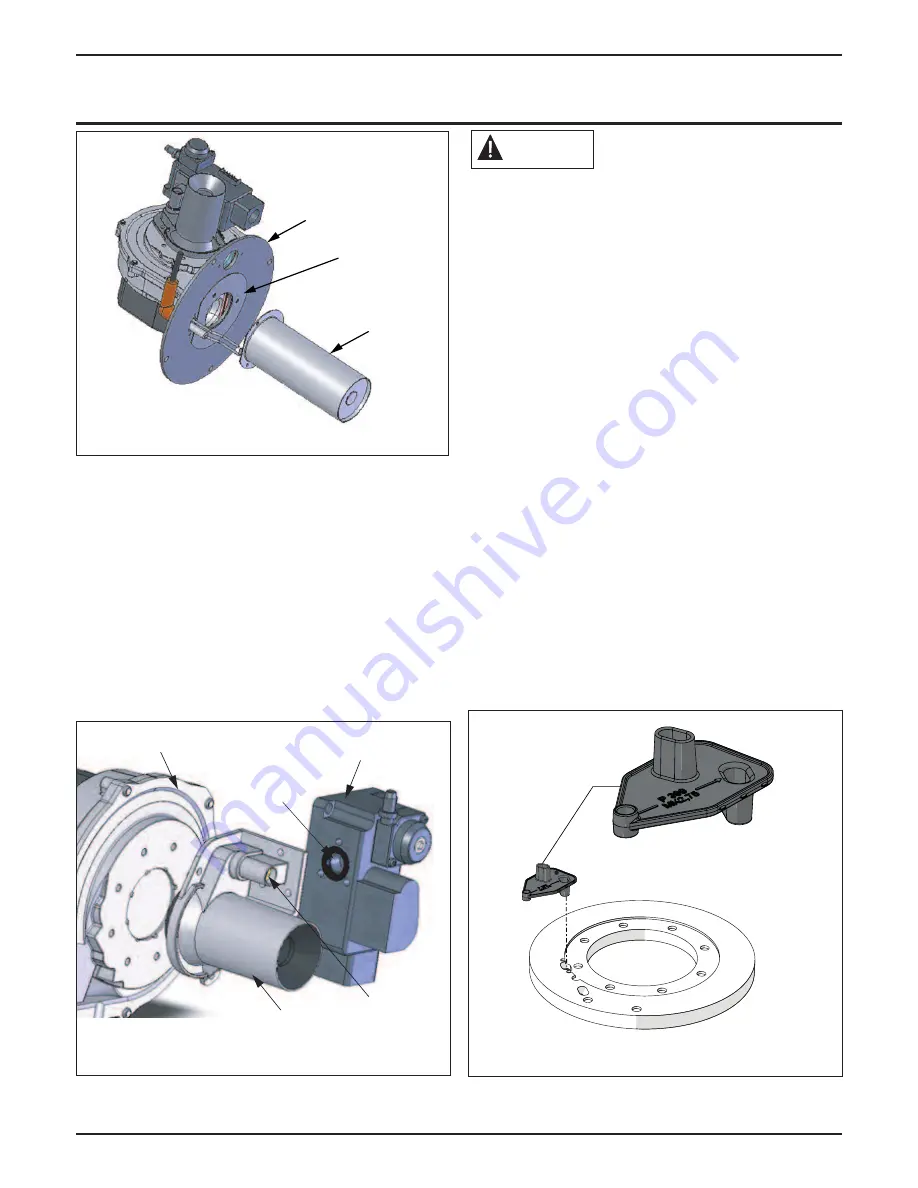

18. Use the included alignment tool to install the

new combustion chamber insulation in the heat

exchanger.

- Insert the alignment tool into the igniter

opening as shown in Fig. 4.

- Install the new combustion chamber insula-

tion in the heat exchanger so that the align-

ment tool goes over the correct heat

exchanger stud as shown in Fig. 5.

- Remove the alignment tool.

19. Re-assemble the burner mounting plate assembly

onto the heat exchanger. Ensure the burner plate

gasket and combustion chamber insulation is in

place and not damaged, replace gasket if necessary.

WARNING

Burner Head

Burner Mounting

Plate

Burner Head

Gasket

Fig. 2: Burner Head and Gasket Assembly

Gas Valve

Blower

Venturi

Throttle

Screw

Insert Brass

Propane Orifice.

Maintain Black Gasket

on Gas Valve

Fig. 3: Venturi/Gas Valve Assembly

Fig. 4: Alignment Tool Installation