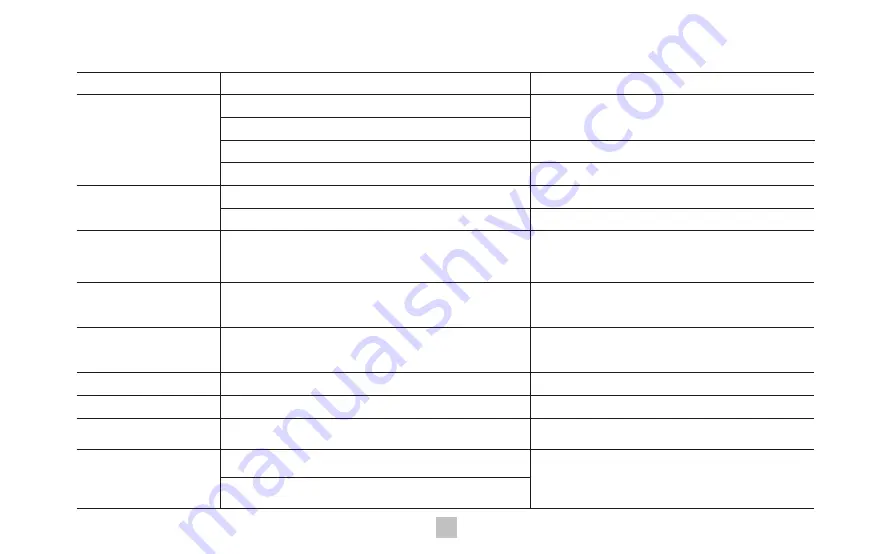

Warning Information

Warning English hints

(

)

Left / right / left and right

fiber placement error

(LFPC / RFPC / LRFPC)

Left / right / left and right

fiber disqualification

(LFNQ / RFNQ / LRFNQ)

Optical fiber angle

disqualification

(FANQ)

Large loss

Alignment abnormal

Fiber end face has dust or quality is poor

Splicing loss exceeds the set upper limit or choose

an unmatched optical fiber type fusion program.

The Arc count exceeds the upper limit

The splicing record exceeds the upper limit

Fiber cutting length is too short

Replace electrodes

Record overrun

Reason

Dust on the fiber's surface

Cut the fiber again and ensure the cutting length

Use alcohol to clean fiber again

Left / right / left and right

fiber's end face disqua-

lification

(LFEANQ /

RFEANQ / LRFEANQ)

Optical fiber end angle exceeds preset limit value

Cut the fiber again, if the quality is poor, please

replace the fiber cleaver

The angle error in both horizontal and vertical

direction is greater than the set threshold value

Replace the fiber on both sides

Please clean the V-groove, redo the discharge

correction, and splice again

Replace electrode and detect system parameters

Please use the USB derive the original splicing

record, then delete them

Please cut and clean the fiber again and make the

alignment. If it doesn't work, please detect system

parameters or restart the machine

Treatment method

The fiber placed in the V-groove has been broken

Fiber is not placed in the middle of the V-groove

Propulsion motor connection problem

Replace the fiber

Please detect system parameters

Poor quality of cutting, core defect, cladding damage Remake the fusion fiber

The windshield cover is too tight and the brightness

of LED lights is not suitable

Lack of electricity

Current battery power is less than 2%

Please insert the adapter to charge

19