23

10

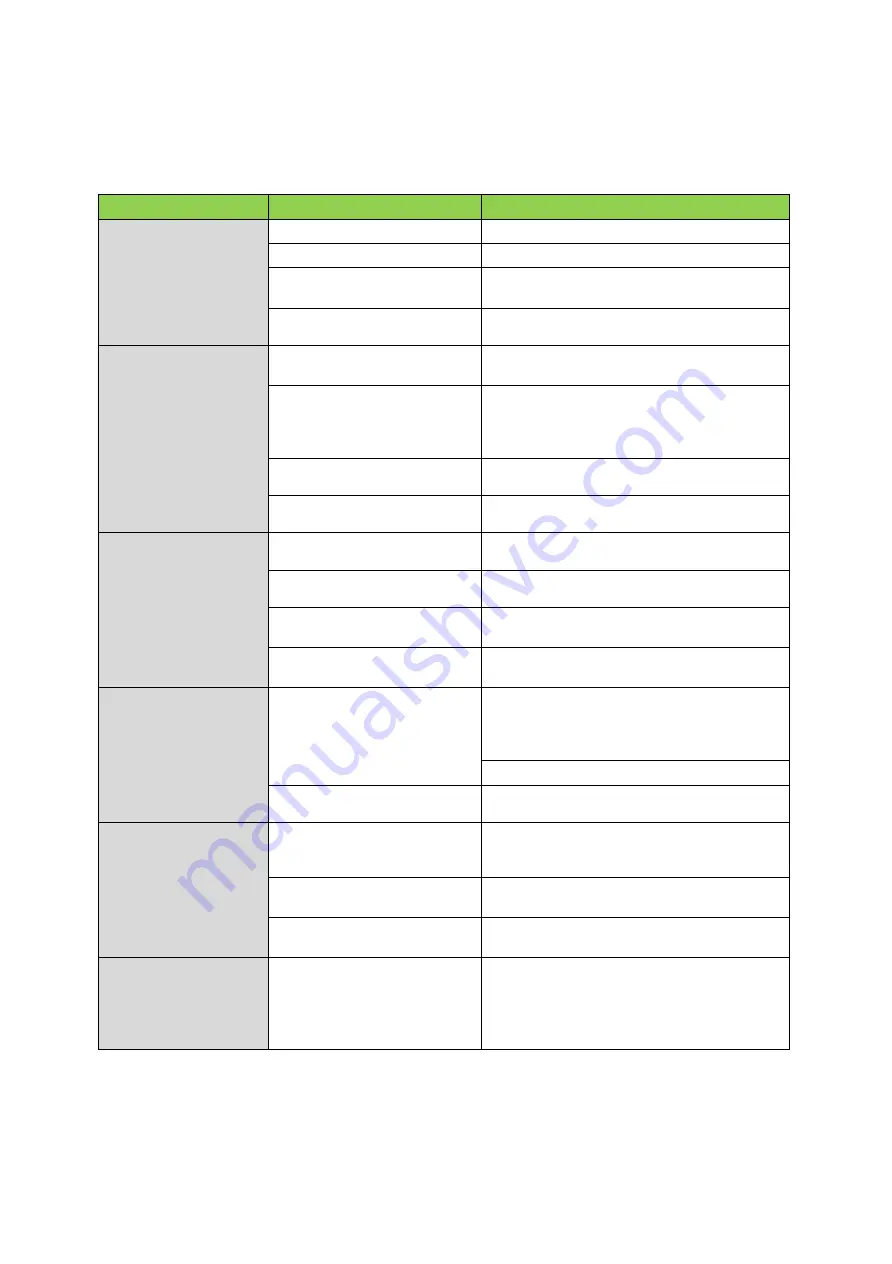

Troubleshooting

10.1

Plant Operation

Symptom

Possible causes

Solution

Pump won’t start or

run

Fuse blown (if applicable).

Replace with fuse of suitable size.

Tripped breaker.

Reset breaker.

Low line voltage and wet

electrics.

An electrician should check the power

supply to the plant.

Defective pump.

Pump must be checked by a qualified

person.

Pump operates but

delivers no water

Low line voltage or wired

incorrectly.

An electrician should check the power

supply to the plant.

Something caught in

impellers.

Clean out impellers or replace pump.

WARNING: Ensure pump is disconnected

from the mains before you attempt to

unclog it.

Delivery hose blocked.

Find blockage and remove or replace

damaged hose.

Other pump malfunction.

Pump must be checked by a qualified

person.

Plant fills above

working water level

Pump not working.

Check pump is functioning properly as

above.

Float from the pump stuck.

Ensure the float on the pump is set correct

and can move freely.

Storm water flooding.

Redirect storm water drains. Storm water

must never enter the plant.

Discharge hose/pipe

blocked.

Find blockage and remove or replace

damaged hose/pipe.

Pump runs

intermittently

Thermal overload tripped.

Check for clogged impeller.

WARNING: Ensure pump is disconnected

from the mains before you attempt to

unclog it.

The pump has run dry so add water.

Damaged float.

Pump must be checked by a qualified

person.

Alarm is lighting but

the pump and is

working

High level float is snagged

or caught on the side of the

tank.

Free the high-level alarm float; unsnag it

from the side of the tank.

Electrical fault.

Get a qualified person to check that the

alarm is installed correctly.

The electrical panel is wet.

Get a qualified person to check that the

alarm is installed correctly.

Build-up of grease

and fat particularly on

the float switches and

pumps.

Build-up of grease and fat

may happen over a long or

short period of time

depending on type of

material entering the tank.

The float and pump may need to be

withdrawn for hosing down. Once the

pump and float has been cleaned, they

will operate in a more efficient manner.