13

5.5.1.2

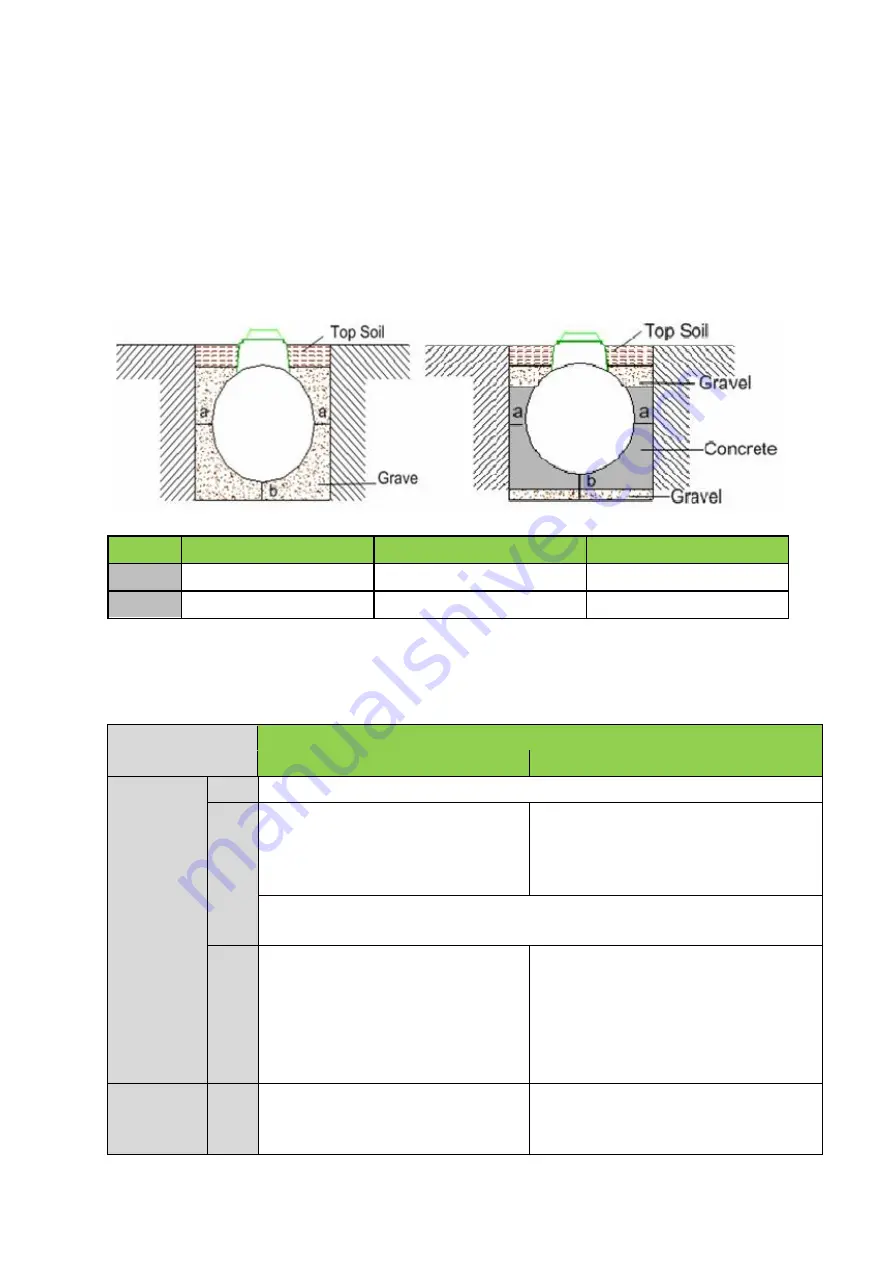

Excavation: Depth

The excavation depth is determined by the inlet and outlet pipes, invert levels relative to the bottom of the

tank, and allowing for the minimum base thickness. Dimension details of the tank are shown on the

relevant drawing, see Section 3.2. Ground instability e.g. running sand may necessitate over-excavation

and stabilization with hard core or blinding concrete. The depth of the excavation for both gravel and

concrete installations are outlined as follows:

Tank Width (mm)

“a” minimum (mm)

“b” minimum

(mm)

Dry Site

1640

250

250

Wet Site

1640

250

300*

*

includes 50mm gravel and 250mm concrete.

5.5.2

Installation

–

Step by Step Guide

Steps

Installation Required

Gravel

Concrete

Installation

of the tank

base/plinth:

1

Remove any soft spots or large stones and boulders.

2

The base is constructed of a 250mm

layer of suitably compacted gravel.

The base is constructed of a 50mm layer of

suitably compacted gravel, covered with a

250mm layer of semi dry concrete.

3

Ensure that base is level and at the correct height to accommodate the incoming pipe

work.

4

It is important to maintain a completely dry

excavation until the final pour of concrete is

set. It may be necessary to line the

excavation with a continuous layer of 1200-

gauge polythene to maintain the integrity of

the concrete.

Positioning

of tank onto

5

Mechanically lift the pumping chamber

carefully into the centre of the hole and

place on the prepared plinth.

Mechanically lift the pumping chamber

carefully into the centre of the hole.

Summary of Contents for Pumping Chamber 2600

Page 7: ...7...

Page 20: ...20...

Page 23: ...23 6 1 1 Operating Performance Tricel 75...

Page 24: ...24...

Page 26: ...26 6 2 1 Operating Performance GRI 11...

Page 35: ...35 Notes...