14

the

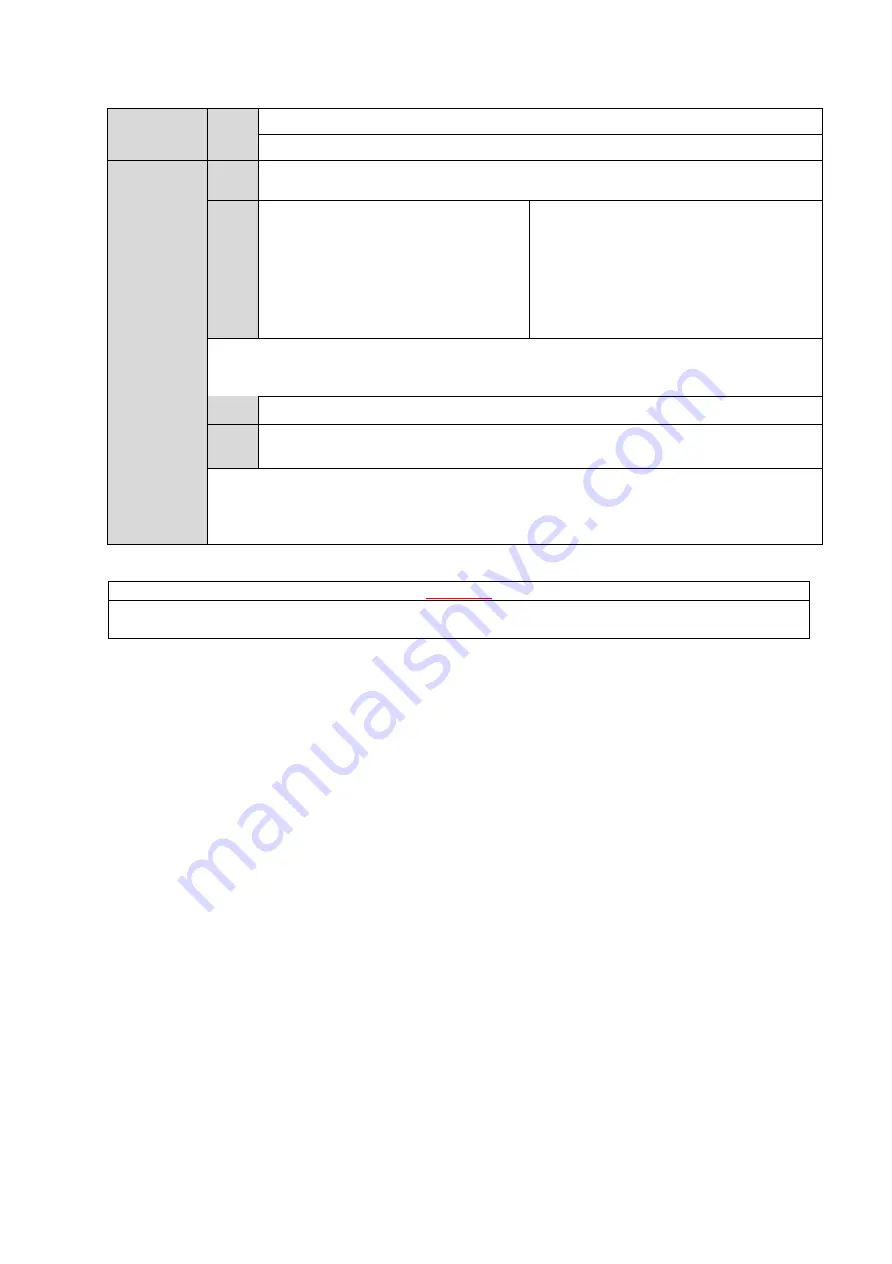

base/plinth:

6

The plant must sit level on the plinth.

7

Connect and seal the pipe work to the tank.

Backfilling

around the

tank:

8

Ballast the plant by filling each chamber with clean water to a depth of 300mm and

recheck the pipe work levels.

9

Commence backfilling with gravel in

layers of 225mm evenly around the tank

ensuring that there are no voids until

gravel has reached 50mm over the

cylindrical body of the tank. Compact

each layer in succession. *

Commence backfilling evenly in layers of

225mm around the tank, ensuring that there

are no voids, until it has reached the invert of

the outlet pipe. Continue backfilling with

gravel, until it has reached 50mm over the

cylindrical body of the tank. *

Note:

* Continue filling the chambers with water whilst backfilling, ensure that the progressive water level

is no more than 300mm above the backfill level.

10

Mount and seal manhole risers (if used). Please see 'Riser' section.

11

Complete backfilling with topsoil up to the max ground level. Allow for subsequent

settlement of topsoil.

Note:

The use of geo textile barrier fabrics over the gravel backfill is considered good installation

practice. The fabric must be chosen to allow the flow of water in and out of the excavation but

to prevent the movement of fine soil particles into the gravel backfill.

Important

The plumbing to and from the plant should be completed by a competent person in accordance with

national regulations and best practices.

5.6

Gravel Specification

Primary backfill specification

Primary backfill material should be free-flowing granular material. Compaction should be by lightweight

rollers or vibratory plate compactor until “traffic” depth has been achieved. Compact gravel evenly to

ensure tank is properly supported. Ensure the vibrating machine does not come in contact with the shell

of the tank. Tanks must be installed with primary backfill only within the region immediately

surrounding the tanks. This primary backfill must extend a minimum of 250mm outward from the tank,

and directly beneath the tank.

The following materials are approved as primary backfill:

Rounded pea gravel

•

Minimum particle size 3mm, maximum 18 mm, compacted to a relative density of >70%. Gravel

shall be clean and free flowing, free from large rocks, dirt, sand, roots, organic materials or

debris. Upon screening analysis, the backfill material shall have no more than 5% by weight

passing 2.36 mm Sieve

Summary of Contents for Pumping Chamber 2600

Page 7: ...7...

Page 20: ...20...

Page 23: ...23 6 1 1 Operating Performance Tricel 75...

Page 24: ...24...

Page 26: ...26 6 2 1 Operating Performance GRI 11...

Page 35: ...35 Notes...