1235 Hickory Street; Pewaukee, WI 53072

For Customer Support: 800-558-7008

for safe usage. Check continuity before starting.) Always check with a safety engineer

when any question arises and periodically check safety procedures with a safety

engineer.

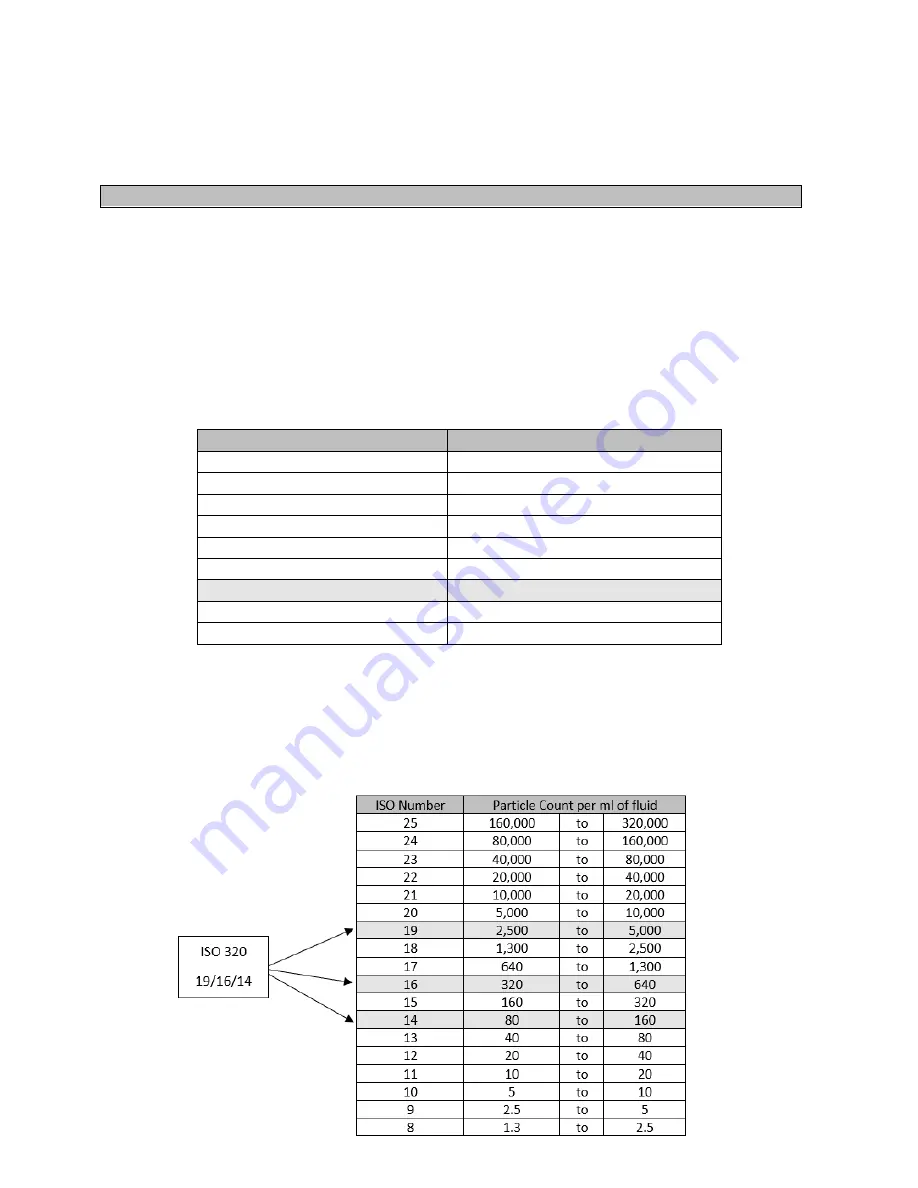

ISO Cleanliness Rating

Lubricating oils stored in bulk containers may contain contaminates. Ordinarily it has

been thought lubricants stored in drums prior to use were contaminant-free; however, it

has now been learned it is beneficial to filter lubricants even prior to its use as the

original container may impart impurities to the lubricants prior to its first use. Most

rotating equipment is manufactured to a class 2 or class 3 fit typical of most industrial

operations. Hydraulic components and rotary screw compressors tend to have tighter

tolerances in the sliding and rotating elements. Clearances in components are used to

establish cleanliness requirements. The best source for cleanliness requirements is

from the equipment manufacturer. In general, as the viscosity of the oil increases the

cleanliness level decreases. Below is a general guideline for cleanliness levels.

ISO Oil Grade Classification Cleanliness Code (R4/R6/R14)

32

16/14/11

46

16/14/11

68

17/14/12

100

18/15/13

150

18/15/13

220

19/16/14

320

19/16/14

460

19/16/14

680

20/18/14

Determining the ISO Cleanliness level of equipment requires analysis of the running

lubricating oil. Trico’s oil analysis laboratories can provide an accurate indication of the

ISO Cleanliness level of lubricating oil before and after filtration. Each number in the

ISO code represents the micron range of particulate in which the count lies within (R

4

microns

/ R

6

microns

/ R

14

microns

).

Example: 19/16/14, the 19 code shows that count of 4

micron particle lies between 5,000 and 2,500 per ml of fluid.