(

215-293-0700

7

215-293-0701

11

Installation and Operation Guide

Proven

Priming

Performance

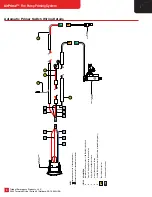

Multi Location Installation and Operating Instructions

Key Points for All Installations

1. The AirPrime unit

MUST

be

VERTICALLY

mounted

ABOVE

the highest priming point in suction piping.

2. All Remote Priming Valves (RPV)

MUST

be mounted

ABOVE

the highest priming point in the suction piping.

3. If the RPV priming valve is mounted below the AirPrime unit, add drain lines from all low points to a drain valve to prevent freezing.

4. It is common to have up to four (4) remote locations with AirPrime Multi-Location priming systems.

5. If front suction pre-priming is required, refer to drawings on the bottom

Pages 11

and

12

for installation recommendations.

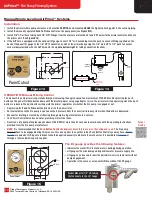

Installation Notes for Multi-Location Priming Systems

1. For

Automatic System

: Follow the instructions on

Page 6

and

Page 7

with lift gauge for mounting the first control on the pump panel.

2. For

Automatic System

: Refer to schematic in

Figure 17

on

Page 11

for air tubing, electric wiring and suction plumbing.

3. For

Automatic AirPrime Connections

: See

Figure 7

on

Page 6

and information on

Page 5

.

4. For

Manual System

: Follow the instructions on

Page 8

for mounting the first control on the pump panel.

5. For

Manual System

: Refer to schematics in

Figure 16

on

Page 10

for air tubing and suction piping.

6. For additional priming locations mount a Push-Button Control as shown in

Photo 5

.

7. Identifying

Gold Labels

are provided for

LEFT

,

RIGHT

,

FRONT

and

REAR

remote priming locations as shown in

Photo 6

.

8. See

Photos 3

and

4

to note that the cast in arrows on the RPVs and Check Valves are in the proper flow direction.

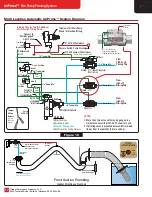

Operating Instructions for Multi-Location Automatic Priming System

1. See operating instructions for the Auto Priming System on

Page 6

for the initial fire pump priming procedures.

2. Be sure the AirPrime switch is in the

AUTO

PRIME

position when opening a remote location valve control.

3. To pre-prime a remote location, push in the

PRIME

button of that location for 45 seconds or until water appears at top of the hose.

Operating Instructions for Multi-Location Manual Priming System

1. Refer to the operating instructions for Manual Priming System on

Page 8

for the initial fire pump priming procedures.

2. To pre-prime a remote location, push in the

PRIME

button for that location for 45 seconds or until water appears at top of the hose.

3. Be prepared to push the

FIRE PUMP

PUSH TO PRIME

button when a remote location valve is opened to remove any trapped air.

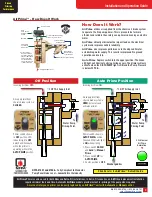

Multi-Location Components

1. Primer solenoid and Multi Location air inlets are shown below in

Photos 1

and

2

.

2. The Remote Priming Valve (RPV) and Air Line Check Valve include flow direction arrows as shown in

Photos 3

and

4

below.

3. Additional pre-priming panel control valve and location labels are shown in

Photos 5

and

6

.

Front View of

AirPrime

Unit

Solenoid

Air Supply

Connection

Additional

Air Inlets

Plug the

Unused Ports

™

1

2

3

4

5

6

Flo

w D

ire

ctio

n

Air

Flo

w

12/24 Volt Solenoid Valve

Manual AirPrime/Remote Location Valve

Air Line Check Valve

Remote Priming Valve (RPV)

Remote Priming Valve Labels

Auto AirPrime Air Connection Ports