(

215-293-0700

7

215-293-0701

15

Installation and Operation Guide

Proven

Priming

Performance

Trouble Shooting Guide (Continued)

Problem

Likely Cause

Corrective Action

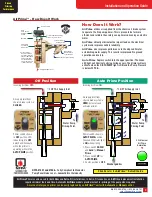

Slow Prime Time.

Leaking air into the

plumbing system.

Double check all drains, discharge, and intake valves to make sure all are

closed.

Low air pressure.

Check air pressure at supply side of AirPrime (Should be over 70-PSIG/

[3�8

Bar]

). Install a tee and air gauge in air line for test purposes. If the air pressure

is not the same as the cab dash air pressure gauge, check for an under sized

airline, kinks or obstructions in air line. Or the air line may be too long (Must be

under 20 feet

[6 m]

from primary tank).

Pressure Protection Valve.

Check Pressure Protection Valve air on/off settings (should shut-off in 60 to

80-PSIG /

[4�2 to 5�5 Bar]

range) and OPEN no higher than 80-PSIG /

[5�5 Bar]

to

AirPrime.

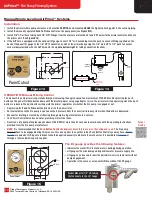

Check wye strainer on

intake from fire pump,

could be clogged.

Remote primer installation: The line from the fire pump to the AirPrime has

a wye type strainer just before connecting into the primer body. Remove the

plug, then strainer, and clean the strainer of debris, reinstall strainer and plug.

a) Direct mount on Hale pump installation: Remove the primer from the Hale Q

fire pump, check the black plastic strainer for debris (Supplied by Hale).

Check Air line to the

AirPrime

.

The air supply line from the air tank is either kinked, undersized or over length.

Replace air line accordingly (

NOTE:

Found mainly on new installations).

Check discharge and

intake valves.

Cap or plug the discharge and intake valves to prove the valves are not leaking

air into the plumbing system (Hydrostatic pump test is useful for such testing).

Check gated Master Intake

Valves on suction intakes.

a) Remove the MIV and cap intake.

b) Install a cap on the discharge side of the relief valve.

c) Cap the Storz or NH intake.

Check the AirPrime internal

priming valve.

a) The priming valve is not seating in the shut-off position, remove primer,

disassemble, and check the priming valve spring, seat, and operation.

b) The priming valve is “stuck”. Check for damaged O-Ring or check to see

that the piston is still fully threaded on the valve stem.

Suction lift too high.

Do not attempt lifts exceeding 24 feet

[7�3 m]

.

Blocked suction strainer.

Remove any obstructions or debris from hose strainer, do not allow suction

hose or strainer to rest on the bottom of the water supply.

Leaking Suction Hose

connections.

Clean and tighten all suction hose connections, check hose washers and

replace as necessary.

Air Trap in suction line.

Suction hose should be positioned with a constant decline to the water supply.

If a trap is unavoidable, repeated priming may be required to eliminate air

pocket.

Multi Location Specific

Problem

Likely Cause

Corrective Action

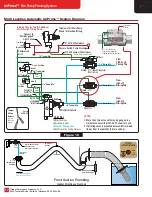

Trouble Priming

or Pre-Priming

from Locations

Other Than

Pump.

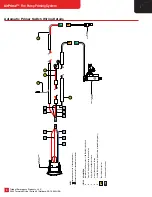

Not priming from highest

suction plumbing point.

Check suction plumbing elevations, shown on bottom of Pages 10 and 11.

Check for changes in suction high point when truck is drafting on an incline.

Remote Priming Valve

(RPV) not opening.

Defective RPV, defective panel push button, check system plumbing using

schematics on

Page 10

(Automatic)

Figure 16

and

Page 11

(Manual)

Figure 17

.

Water trap in RPV line.

Lines must ascend from highest suction plumbing points to RPV(s) for natural

drainage and to avoid water traps.

AirPrime

™

Industrial and SC Systems

AirPrime units are available for high volume Industrial Pumpers/Trailers with engine driven air compressors. Also available for small

Wildland Trucks without air brakes by utilizing a SCBA cylinder. Visit

via email for more information.