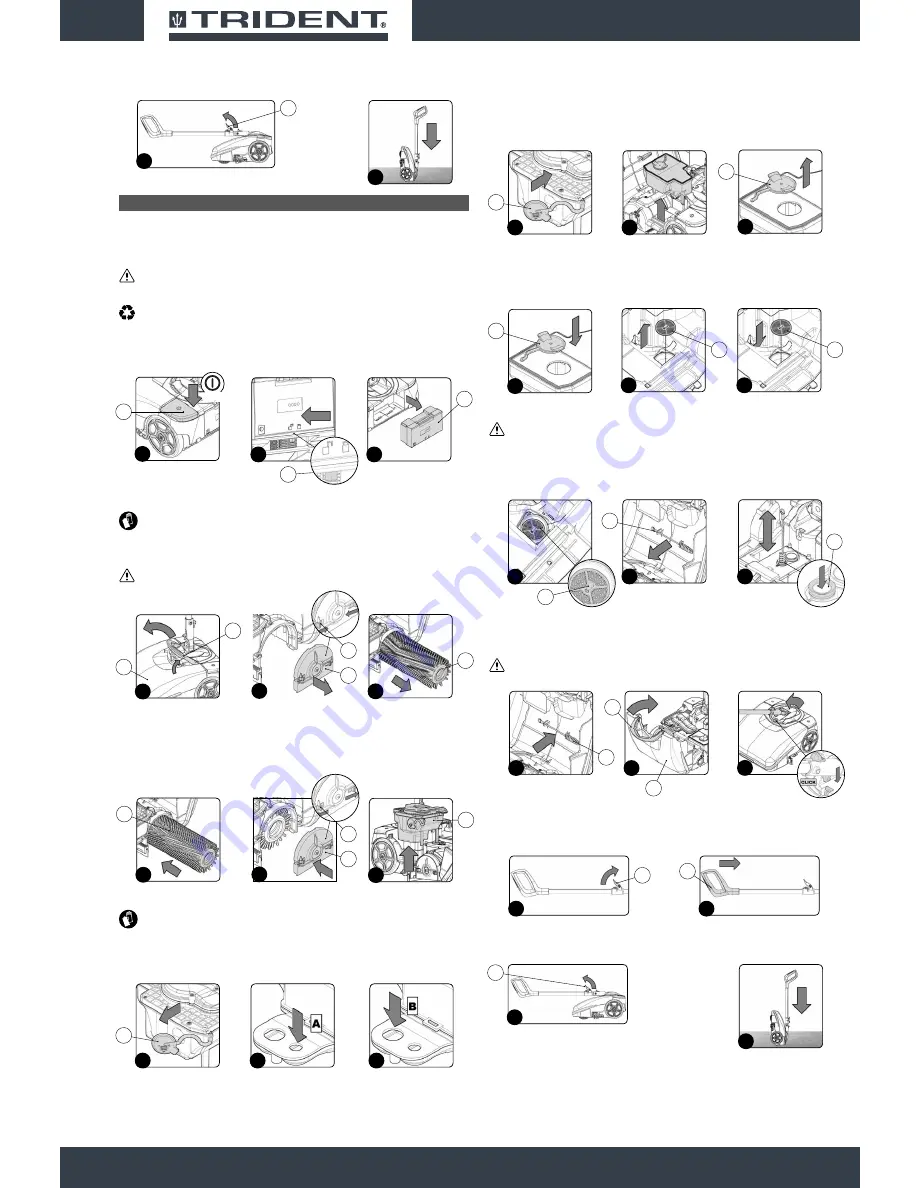

MAINTENANCE

At the end of the work, and before carrying out any type of maintenance, perform the following

operations:

1.

Switch off the machine using the main switch (1) (

Fig.1

).

2. Rotate the handlebar so it is vertical.

CAUTION

: During this operation, do not rest your foot on the machine.

3. Take the machine to the designated maintenance area.

N.B

: the place designated for this operation must comply with current environmental protection

regulations.

4. Remove the battery (2) from the battery compartment; to free the battery, shift the stop lever (3) in

the direction of the arrow (

Fig.2

).

5. Remove the battery from the battery compartment using the handle moulded on it (

Fig.3

).

6. Rotate the front carter (4) as far as it will go - do this with the aid of the handle (5) (

Fig.4

).

CAUTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

7. Remove the tunnel cover (6) and shift the stop levers (7) as indicated by the arrows (

Fig.5

).

8. Remove the brush (8) from the machine (

Fig.6

).

ATTENTION:

During this operation, keep the control handlebar still, in order to prevent the

machine from moving accidentally.

9. Clean the brush under running water and remove any impurities present in the bristles of the brush.

Check that the bristles are not worn; in the event of excessive wear, replace the brush (the bristles

should be at least 10 mm long).

10. Fit the brush (8) on the pin in the brush motor (the brush can only be inserted in one direction)

(

Fig.7

).

11. Replace the tunnel cover (6) and shift the stop levers (7) as indicated by the arrows (

Fig.8

)

12. Remove the recovery tank (9) from the machine (

Fig.9

).

13. Remove the drain plug (10) on the recovery tank from its seat (

Fig.10

).

ATTENTION

: protective gloves should always be worn before handling detergents or acidic or

alkaline solutions, to avoid serious injury to the hands.

14. Clean with a jet of air

the vacuum motor air channel chamber, the chamber inlet hole is marked

with the letter (A) (

Fig.11

).

15. Clean with a jet of air

the dirty water channel chamber, the chamber inlet hole is marked with the

letter (B) (

Fig.12

).

16. Rinse the inside of the tank with a jet of water.

17. Insert the drain cap (10) in its seat on the detergent solution tank (

Fig.13

).

18. Remove the solution tank from the machine (

Fig.14

).

19.

Remove the filling cap (11) from its seat on the solution tank (

Fig.15

).

20. Rinse the inside of the tank with a jet of water.

21.

Replace the filling cap (11) in its seat on the detergent solution tank (

Fig.16

).

22.

Remove the filter cartridge (12) and clean it under a jet of water to remove any impurities that might

be attached. If necessary, replace it (

Fig.17

).

23.

Insert the filter cartridge into its seat in the frame (12) (

Fig.18

).

ATTENTION:

Put the filter cartridge in its seat as shown in

figure 19

, the valve activation pin

(13) should be facing up.

24.

Insert the two tanks in the machine, positioning first the solution tank and then the recovery tank.

25. Remove the vacuum duct cleaning brush (14) from its support (

Fig.20

).

26. Clean the inside of the vacuum duct (15) with the brush (14) (

Fig.21

).

27. Put the vacuum duct cleaning brush (14) in its support (

Fig.22

).

28. Rotate the front carter (4) as far as the work position; do this with the aid of the handle (5) (

Fig.23

).

29. Block the handlebar in the horizontal position (

Fig.24

).

ATTENTION:

During this operation, do not rest your foot on the machine.

30. Turn the stop lever of the command handlebar (16) in the direction of the arrow (

Fig.22

).

31. Close the command handlebar again, pushing the handle (17) towards the body of the machine

(

Fig.23

).

32. Turn the stop lever of the command handlebar (16) in the direction of the arrow (

Fig.24

).

33.

Position the machine with its rear in contact with the floor (

Fig.25

).

12

10

10

11

12

17

16

10

10

13

14

11

15

1

1

OFF

3

2

2

3

5

4

4

8

6

6

5

7

9

9

8

6

7

8

7

11

16

17

18

12

12

19

13

20

21

14

15

5

4

23

14

22

24

22

16

23

17

24

16

25