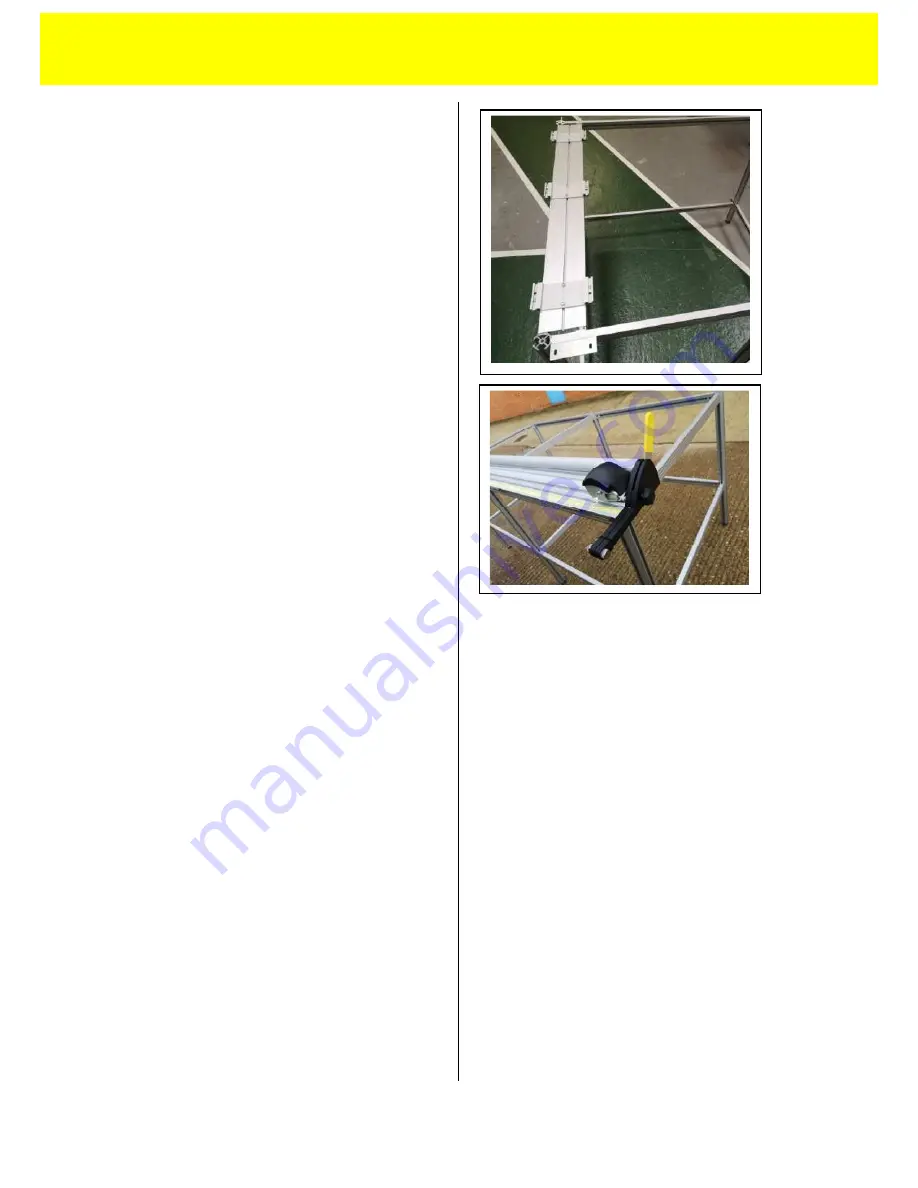

POSITIONING THE BASE LOCATING BRACKETS &

MOUNTING PLATES

Position a bracket & plate assembly 10 cms (4”)

inboard from either end of the Athena Support

Beam. Position the remaining assemblies along

the length of the Athena Support Beam with equal

spacing between each. If one of the bracket

assemblies coincides with a centre frame beam

simply move that bracket to either side of the it.

FITTING THE CUTTER ASSEMBLY

Lift the cutter assembly and place it centrally on

the locating brackets. The larger cutters are

heavy and this will require two people.

Remove the clear stretch wrap and gently

manoeuvre the assembly until it is located

properly on each of the brackets. Slide the

assembly left or right so that the holes in the fixed

arms line up with holes in the support brackets

fitted to the table. Insert the four button head

screws and nuts (included with the table) at this

point but do not tighten.

Loosen by one full turn anti clock-wise, the four

hexagon screws (two at each end) joining the

fixed arms to the cutter base (see 4.2). Now

tighten the four button head screws fully insert

the two wood screws.

Tighten the grub screws at the back of each

bracket (see 4.1 picture 1) by 8 full turns and then

tighten the front grub screws (see 4.1 picture 2)

up fully (approx 7-8 turns).

The cutter bar is guaranteed to be straight to

within 0.4mm (.016”) along its full length. If you

need to adjust the cutting groove in the base to

match this, follow the instructions in 4.1

7.1 FITTING TO THE ATLAS TABLE

7.1