8

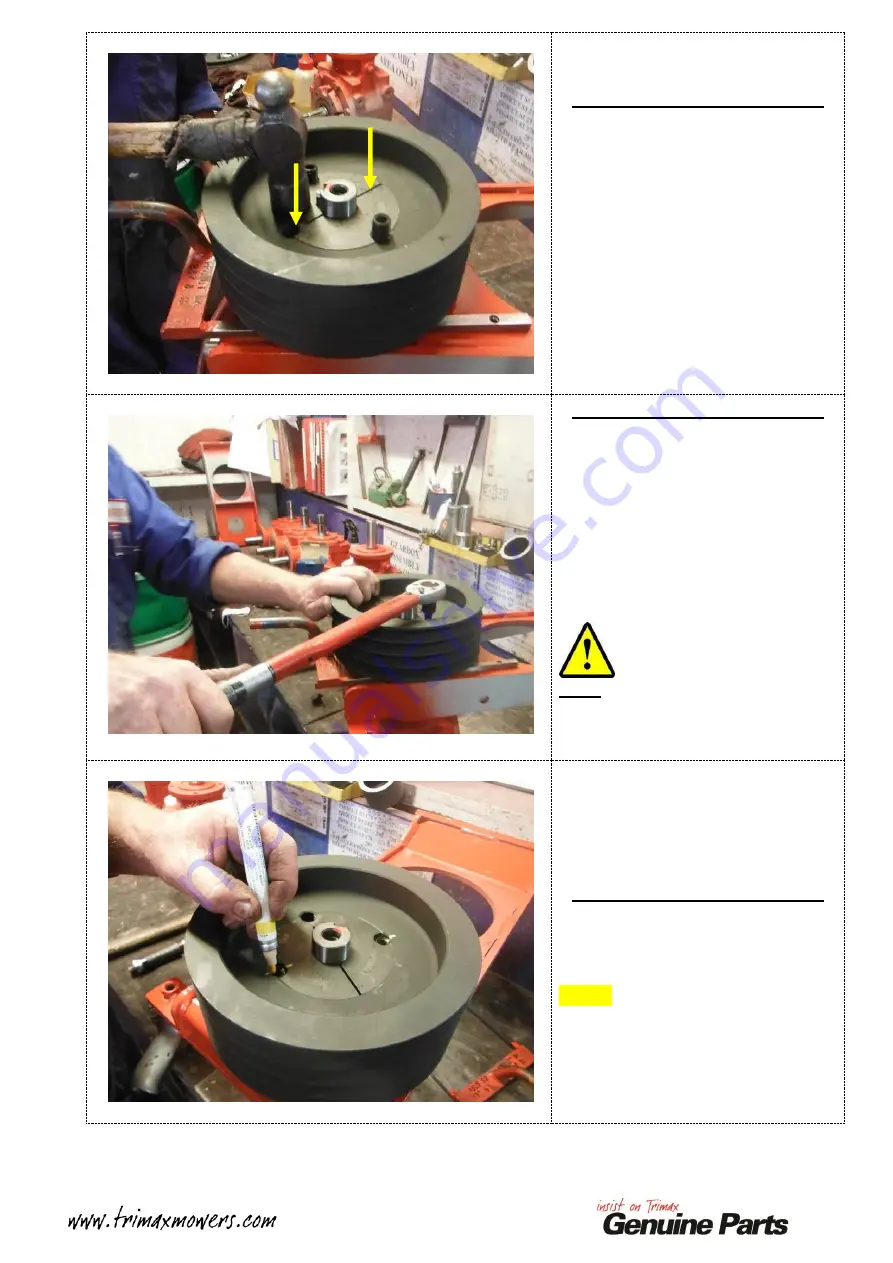

Procut S3 237 and 290 only:

Fit the Gearbox Pulley

Sub-assembly onto the Output Shaft.

Align the Key in the Output Shaft

with the Keyway in the Gearbox

Pulley Assembly.

Lightly tap the Gearbox Pulley

Sub-assembly down until it is hard

against the

10mm (3/8”) Spacers

.

Fully tighten.

Procut S3 237 and 290 only:

Torque the Grub Screws to

90Nm

(66ft/lbs)

Tap around the Bush with a Hammer,

this will ensure that the Bush is seated

squarely in the Bore

Re-torque the Grub Screws to

90Nm

(66ft/lbs)

This ensures that the Pulley

is securely mounted.

Note:

It may be necessary to prevent the

Gearbox from rotating, an old P.T.O

Yoke can be used for this task.

Procut S3 237 and 290 only:

Once torqued, remove the Spacers.

Stripe across the Grub Screws with a

Yellow

Paint Marker