10

ANLEITUNG 04_21

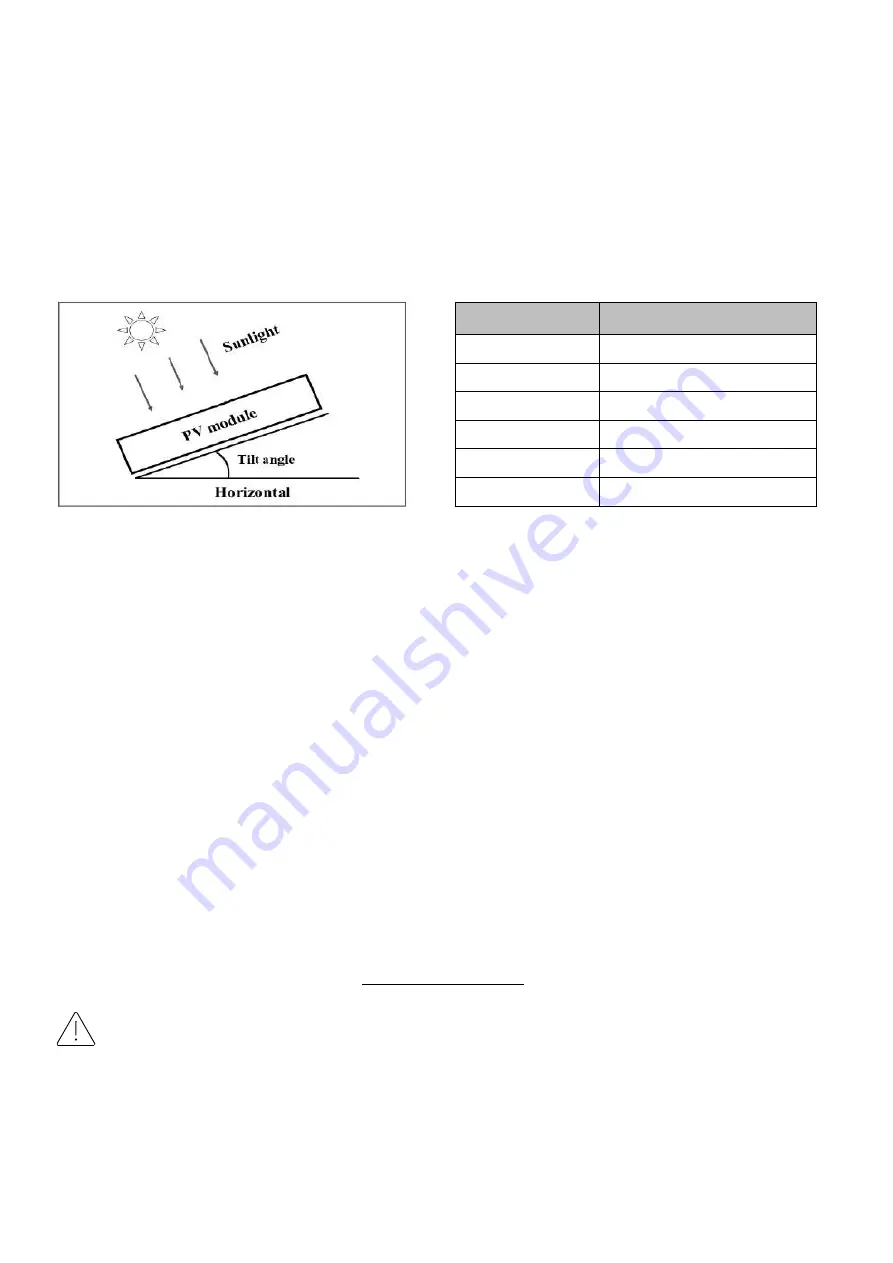

Tilt Angle

PV modules should be installed in a location where they can receive the maximum amount of sunlight

throughout the year. In the Northern Hemisphere, the modules should face south, and in the Southern

Hemisphere, they should face north. As a rule of thumb, the tilt angle should be approximately equal to the

latitude of the project site and point toward the equator.

PV modules connected in series should be installed in the same orientation and with the same tilt angle. The

greatest power is generated when direct sunlight falls on the PV modules.

Dust and dirt accumulating on the surface of the modules can affect performance. TRIMAX Solar

recommends that modules be installed with a tilt angle of at least 15 degrees so that dust or dirt can be

washed off more easily by rain.

Figure 3: Tilt Angle

Table 3: Tilt Angle

Latitude

Tilt angle

0°

~

15°

15°

15°

~

25°

The same latitude

25°

~

30°

Same la5°

30°

~

35°

Same la10°

35°

~

40°

Same la15°

40°+

Same la20°

Glare behavior / Glare assessment

Under certain circumstances (e.g. nature reserves, traffic routes, airports), it may be necessary to check the

glare behavior of the PV power plant. Factors for the strength of the reflection include the position of the sun,

module orientation, coordinates of the installation site and the surface properties of the solar module.

Contact a professional provider for a glare assessment. TRIMAX Solar high performance PV modules are

coated with an ARC (Anti Reflective Coating). The glass coating with nano technology ensures that less light

is reflected and more light reaches the solar cells.

Bifacial Modules

TRIMAX Solar high power PV modules are equipped with bifacial PERC cells. PERC stands for Passivated

Emitter Rear Cell. The structure of the PERC cell essentially allows for improved light output at the rear of

the cell, which in turn increases electron yield. The bifaciality (the ratio of front and rear output under the

same conditions) can reach 65% ± 5%. The bifacial extra yield depends mainly on the system design, especially

the row and ground spacing, the angle and the reflectivity of the ground (albedo). Additional yields between 5

and 15% are possible. The reflectance varies depending on the soil resulting in different power generation. The

irradiance reflected to the back of the bifacial glass/film solar modules must not exceed 300 W/m2.

Electrical design

Maximum system voltage (Umax): 1000V or 1500V depending on product type.

Please check the nameplate and data sheet accordingly. For further technical data, please refer to the

respective data sheets - available online at www.trimax-solar.com.

•

To avoid power loss or damage to the PV system, use only modules of the same type and

power within the same circuit.

•

Protect the solar modules from overvoltage, e.g. voltage peaks from battery charging,

generators, etc.

•

Only use plugs of the same manufacturer and type for cable extensions.