12

Blade Replacement

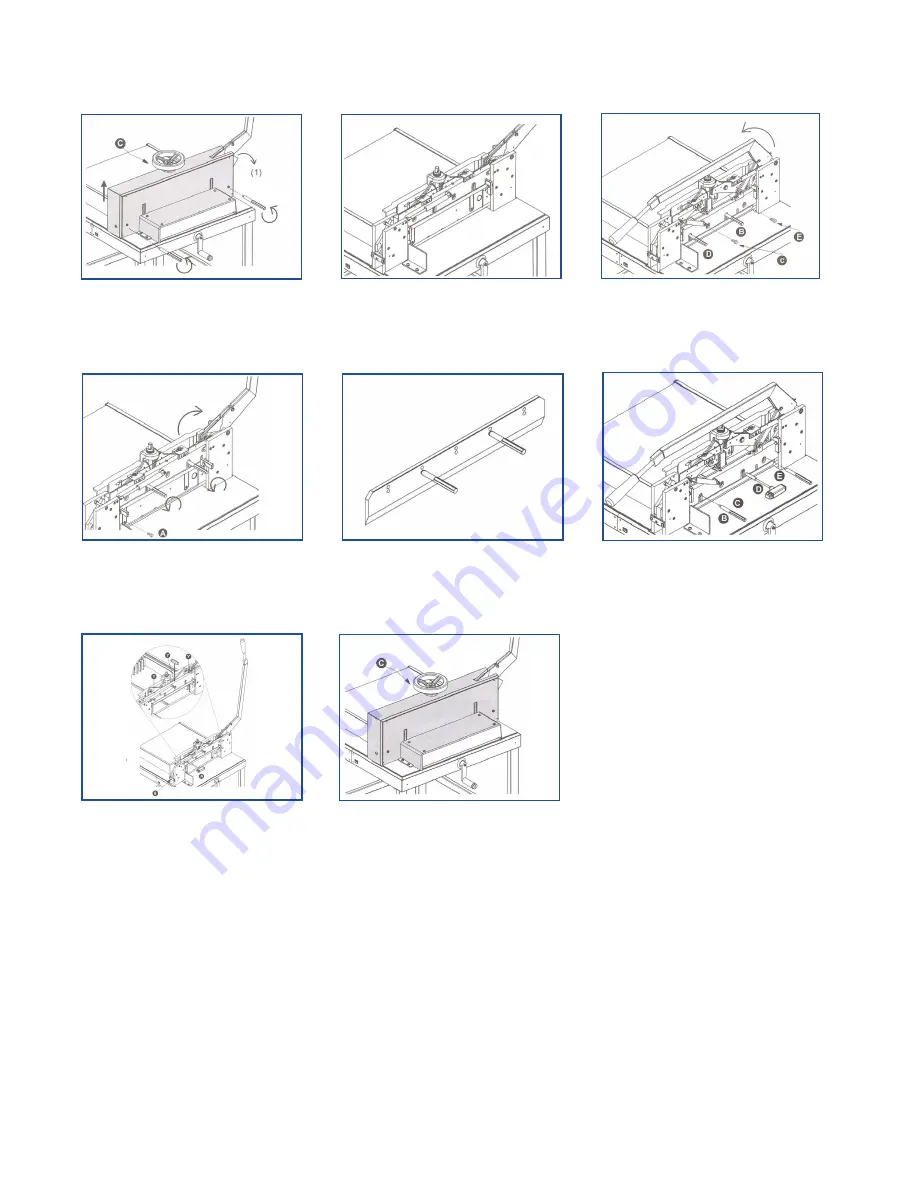

For Cutters with a Spindle Hand Wheel:

5. Remove the knife holders and the old blade,

replace this with a new blade. Screw the

knife holders back into place. Insert the knife

holders into the opened second & fourth hole

of the blade carrier and fasten.

6. Lower the knife lever until this is horizontal,

tighten the knife screws (c & e) remove the

knife holders, then fasten the knife screws

(b & d).

1. Remove the safety gadget (1). Raise the

knife lever. Remove the screw (c) on the clamp

wheel. Remove all the screws fixed on the

cover. Place the knife lever at 75 degrees and

remove the knife cover.

2. Lower the knife lever until this is horizontal.

4. Return the knife lever to its locked starting

position. Remove the knife screw (a). Loosen

the knife holders (by only half turn) and lower

the blade downwards from the blade carrier

and remove the blade carefully.

3. Remove the screws (b & d), replace them

with the two knife holders from the tool box

and tighten them securely. Remove the knife

screws (c & e).

7. Return the knife lever to its locked starting

position. Screw in the knife screw (a). Move

the knife carefully down to the cutting stick

via the knife lever. Turn the knife adjustment

(8) to the right - until you have a visible ray of

light between knife edge and cutting stick.

Adjust the knife to touch the cutting stick by

adjusting the screws. Move the knife lever to

its locked raised position. Make a trial cut with

one sheet of paper, if the paper does not cut

through totally, then the knife needs adjusting

using the screws (y & 8).

Please note. (8) is for minor up/down

adjustment. (y) is for horizontal adjustment.

8. Place the knife lever at 75 degrees and

assemble the cover. Tighten all screws on the

cover. Assemble the spindle clamp hand wheel

and screw (c) to fix tightly. Assemble the safety

gadget.