OpGL

Globe Control Valve

Product Instruction Manual

Leading Technologies

For Control

INTRODUCTION

Scope of Manual

This instruction manual includes installation,

maintenance, and parts information for the

Optimux OpGL control valve. Refer to separate

manuals for information regarding installation,

operation, and maintenance of additional

features such as the special trim diaphragm

actuator, handwheel, extension bonnets, etc.

Only qualified persons should install, operate,

and maintain an Optimux OpGL valve. Any

questions about these instructions should be

directed to your Optimux sales office or sales

representative before proceeding.

This publication does not contain information on

Optimux positioners. Refer to the appropriate

manual for information on positioner installation,

operation, maintenance, and calibration.

Description

The OpGL is a spring-cylinder actuated globe

valve in which the supply air pressure and the

fluid pressure combine forces to produce an

exceptionally tight shutoff. In addition, self-

aligning seat rings make shutoff easier to

achieve. Valve specifications are as follows:

Table 1: Specifications

TABLE OF CONTENTS

INTRODUCTION

Scope of Manual ............................ pg. 1

Description...................................... pg. 1

Specifications ................................ pg. 1

Safety Information ........................ pg. 1

Unpacking ...................................... pg. 2

INSTALLATION ..............................

pg. 2

MAINTENANCE ............................

pg. 3

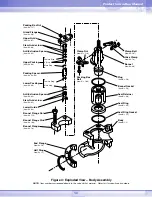

ASSEMBLY AND DISASSEMBLY

Body Disassembly.......................... pg. 4

Body Reassembly .......................... pg. 5

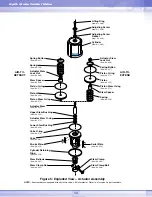

Actuator Disassembly.................... pg. 7

Actuator Reassembly .................... pg. 8

AIR-ACTION REVERSAL

Air-to-Open .................................... pg. 9

Air-to-Close .................................... pg. 9

SAFETY INFORMATION

WARNING

: Indicates a potentially

hazardous situation, which, if not

avoided, could result in

death or

serious injury.

CAUTION

: Indicates a potentially

hazardous situation, which, if not

avoided, could result in

minor or

moderate injury and/or property

damage.

Note:

Indicates a potential situation,

which, if not avoided, may result in an

undesired result or state.

Diameter

Body Style

Connections

Materials

Bonnet Types

Internals

1/2 ’’- 42’’ : ANSI Class 150-600

Globe, Angle, Three-way, Steam-

jacketed, Y-body

Separable flanges, Internal flanges,

Socketweld, Buttweld

Carbon Steel, Stainless steel, Chrome-

molly, Alloy, Hastelloy, B&C, Titanium,

and others…

Normal, Extended, Cryogenic, Coal box

extended

Flow characteristics, equal percentage,

linear, and quick-open. Seats available

in metal or soft (for "bubble tight" shut

off)