9

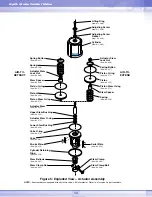

10. Apply air over the piston to drive the plug

and lift the yoke off of the bonnet. The

yoke will lift approximately 1/16-inch

(1.60mm). If the space is not that size,

apply air under the piston to retract the

actuator stem and screw the plug in or out

as needed. Repeat until the 1/16-inch

(1.60mm) space is created.

11. To attach the yoke clamps and packing box

bolting, apply air under the piston. Tighten

the yoke clamp bolting firmly. The packing

box nuts should be just over finger-tight.

CAUTION:

Do not over-tighten

packing.

12. To seat the plug, apply air over the piston.

For all throttling valves, adjust the stem

clamp so that, with full instrument signal to

the positioner, the full signal scribe line on

the positioner cam points to the center of

the cam roller bearing.

Note:

For on/off valves, the bottom of the

stem clamp should line up with the bottom of

the actuator stem (±1/16-inch).

Tighten the stem clamp bolting to secure

the actuator stem to the plug stem. Adjust

the stroke plate so that the stem clamp

points to the "closed" position.

13. Reconnect the actuator/positioner tubing,

supply, and signal lines.

AIR-ACTION REVERSAL

Air-to-Open

To switch the air-action from air-to-close to air-

to-open continue as follows:

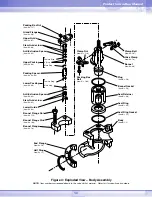

1. Adhere to the instructions for disassembly

of the actuator (see "Actuator Disassembly"

section).

2. Reassemble the actuator with the spring,

actuator stem spacer, and spring button

over the piston. For proper alignment, the

center hole in the spring button should

engage the end of the adjusting screw.

3. The positioner must be changed as well, to

do so, refer to the appropriate positioner

manual.

Air-to-Close

To switch the air action from air-to-open to air-

to-close continue as follows:

1. Adhere to the instructions for disassembly

of the actuator (see "Actuator Disassembly"

section).

2. Reassemble the actuator with spring and

actuator stem spacer below the piston. The

spring should sit in the spring groove on top

of the yoke. The spring button is not used

on air-to-extend configurations and is

stored above the piston (the actuator stem

retaining nut holds the spring button in

place).

3. The positioner must be changed as well. To

do this, refer to the appropriate positioner

manual.

Product In

s

truction Manual