Trina Solar User Manual | Vertex Series Modules

11

6

INSTALLATION

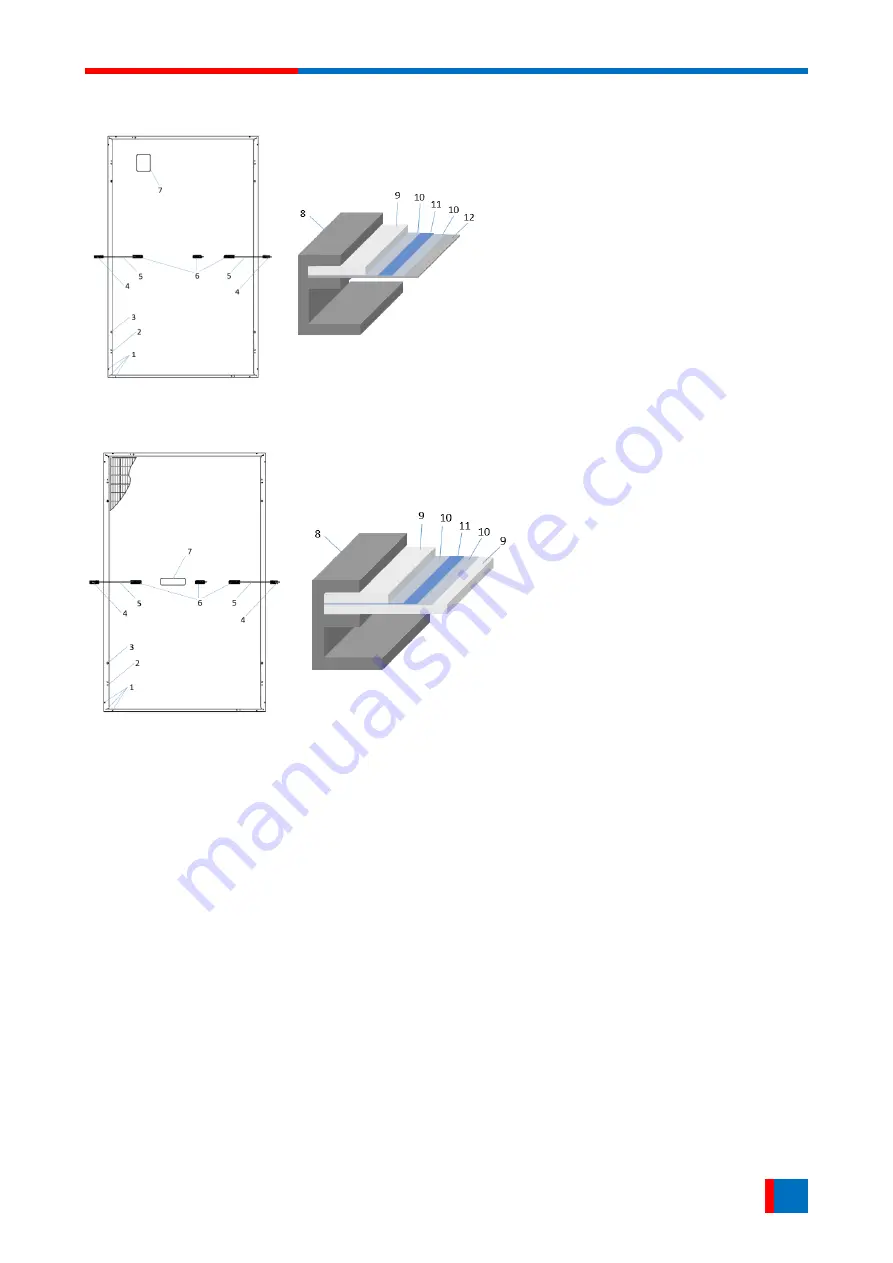

Mechanical drawing for monofacial modules

Mechanical drawing for bifacial modules

6.1 INSTALLATION SAFETY

Trina Solar recommends that PV module installation should only be conducted by specialized

persons with experience in PV system installation. All installation work must be in full compliance

with the local regulations and the relevant international electrical standards.

The fire rating of Trina Solar modules complies with relevant standards or local laws and regulations.

Before installation, please carefully check the modules for abnormalities such as glass bursts, cell

cracks, backsheet scratches, deformation of installation holes, broken junction boxes or missing

covers, nameplates falling off or missing, and broken cables or connectors, etc. If any of such

situation is found, please contact Trina Solar customer service in time.

Before installation, please keep modules' electrical components clean and dry. Connectors can

corrode if they are in connected under wet conditions or with water inside the conductive parts. Any

corroded components shall not be used.

The cable length of junction box shall be selected according to the installation mode. When wiring,

the ties for fixing the cables coils shall be removed. The cable shall be fixed on the installation system

(frame or bracket, guide rail) with UV resistant cable ties, in cable conduits or wire cards to avoid

direct sunlight or immersion in water and mechanical damage of the cable; otherwise, it may cause

accelerated aging of the cable or even leakage and fire. Bifacial PV modules should also avoid

1 Drain hole

2 Grounding hole

3 Installation hole

4 Connector

5 Cable

6 Junction box

7 Nameplate

8 Frame

9 Glass

10 Encapsulate material

11 Solar cell

12 Backsheet