Trina Solar User Manual | Vertex Series Modules

13

6.2 INSTALLATION METHOD

The PV modules must be installed in accordance with the installation instructions specified in this

user manual to comply with the IEC certification. Before installing, please read this section carefully

to familiarize yourself with the complete installation processes.

The modules and racking system can be connected through the mounting holes, clamps, or an

embedded system. Installation of modules must be carried out in accordance with the installation

requirements. If you wish to use a different installation method, please consult Trina Solar customer

service or technical support team. If in such case that an alternative mounting method is used but

not approved by Trina Solar, the module may get damaged and the warranty will be invalidated.

The mechanical loads described in this manual are the test loads. For calculating the equivalent

maximum design loads, a safety factor of 1.5 needs to be considered in compliance with the

requirements of the local laws and regulations. The design loads are strongly related to the

construction, applied standards, location and local climate conditions; therefore, have to be

determined by the racking suppliers and/or the professional engineers. For detailed information,

please follow local structural code or contact your professional structural engineer.

The modules shall be mounted on continuous rails that extend beneath the modules. If modules are

mounted without continuous rails, the maximum allowable load will be reduced, which needs to be

re-evaluated by Trina Solar.

The minimum distance between two modules is 5 mm (0.2 inch). If using special trackers, the

minimum distance should be selected according to the technical requirements of the tracker

suppliers.

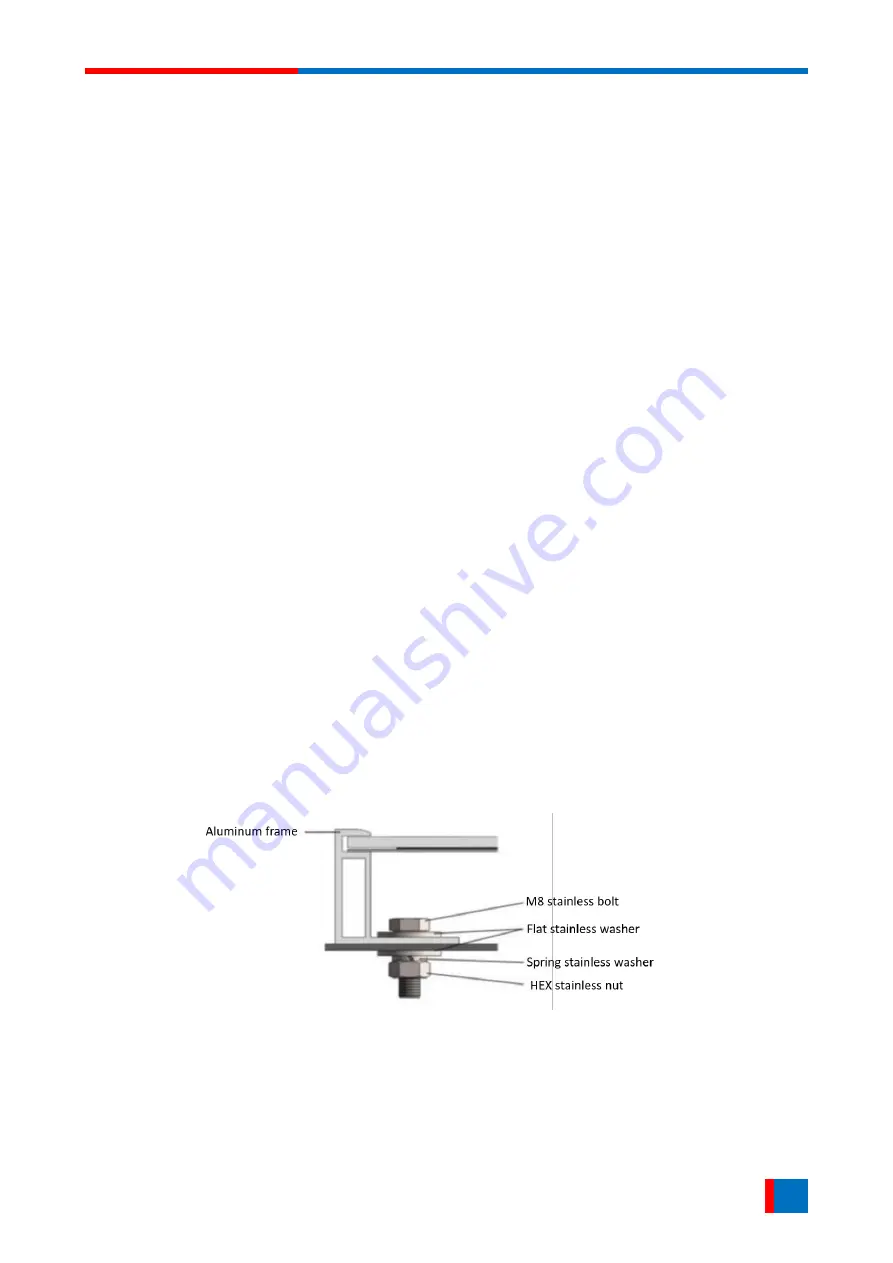

6.2.1

SCREW INSTALLATION

The frame of each module has 4-

φ9*14mm mounting holes, that are ideally placed to optimize the

loading capacity to secure the modules on the supporting structure.

To maximize mounting longevity, Trina Solar strongly recommends the use of corrosion proof

(stainless steel) fixings.

Secure the module in each fixing location with one M8 bolt, two flat washers, one spring washer and

one nut (see Figure 1) and tighten them to a torque of 16-20 N.m (140-180 lbf.in.)

.

The yield strength

of bolt and nut should not be less than 450 MPa.

All parts in contact with the frame should use flat stainless-steel washers of a minimum of 1.5 mm

(0.06 inch) thickness with an outer diameter of 20-24 mm (0.79-0.94 inch), except for DE09 /

DE09.05 / DE09.08 / DEG19C.20 / DE21 using an outer diameter of 16-18 mm (0.63-0.71 inch).

Figure 1. PV module installed with bolt fitting method.