PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24)

17

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

7

Revision history

7.1

Document revision

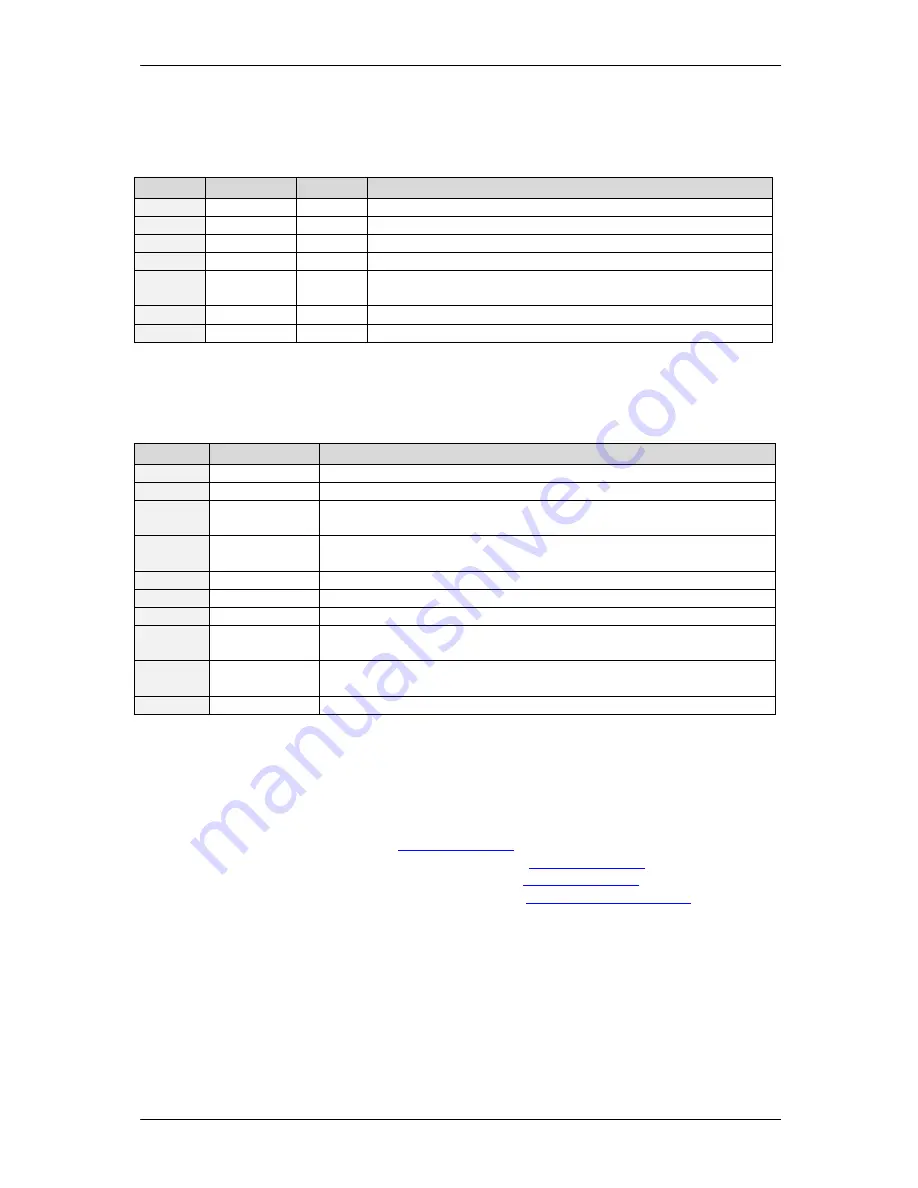

Version

Comment

Author

Description

1.00

2005 – 2007 Dw

Initial Versions

1.05

05-09-2007

HC

Added Documentation Revision and PANdrive™ information

1.06

10-09-2007

GE

Update of dimensions and pictures

1.07

30-10-2007

HC

Encoder graphics added (chapter 6.3)

1.08

21-11-2007

HC

PANdrive

™

encoder resolution info corrected to 2000 per

rotation

1.09

10-12-2007

MJ

Chapter v5.1 extended; Appendix with TMCL-code

1.10

2011-NOV-24 SD

New order codes, new front page, minor changes

Table 7.1: Document revision

7.2

Firmware revision

Version

Comment

Description

0.90

Initial Version

Attention: Use Documentation V0.90 or later for connector pinning!!!

0.92

First release

Added encoder N-channel initialization

0.93

Added encoder N-channel for automatic correction and encoder error

flag

0.94

Allows specifying of CHA and CHB polarity for nulling of encoder –

uses higher bits of Encoder Null Polarity

1.00

Release 1.0

Added operation mode with hall sensors only.

1.01

Corrected RS485 behavior

1.02

Added standalone mode feature

1.03

Fixed RS485 delay problem (master had to wait for timeout time before

sending new command), when multiple units share a bus

1.07

TMCL

Added TMCL

™

standalone program capability, extended command set

for TMCL

™

. Up to 64 commands can be stored in EEPROM.

Table 7.2: Firmware revision

8

References

[TMCL]

TMCL™ Manual,

www.trinamic.com

[TMCM –170]

Reference and Programming Manual,

www.trinamic.com

QBL5704 Manual

QBL5704 BLDC servo motor manual,

www.trinamic.com

HEDS-5640#A12 info

HEDS-5640#A12 encoder information

http://www.avagotech.com