PD-013-42 / TMCM-110-42 Manual (V1.24/2011-NOV-25)

21

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

8

Getting started

8.1

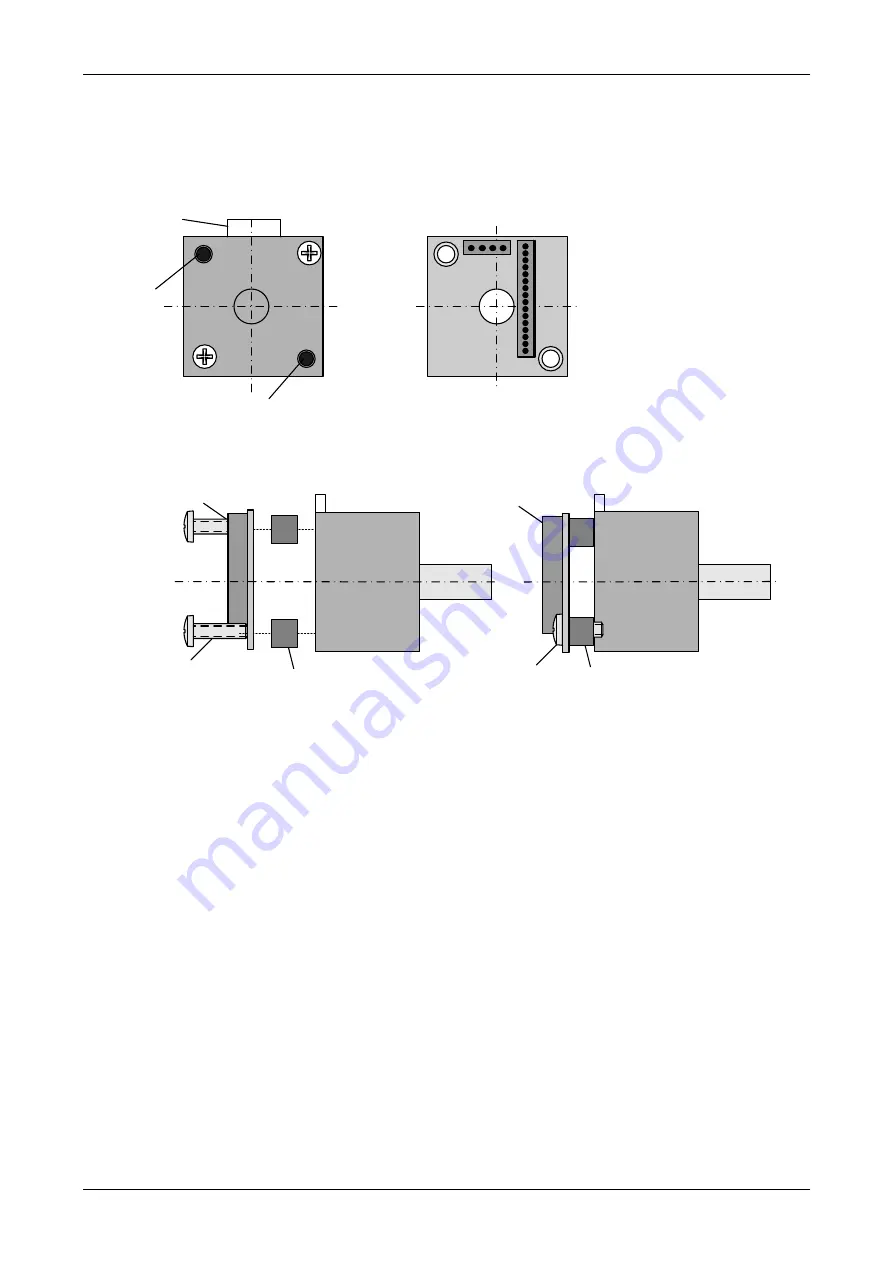

Assembly of parts

TMCM-013

screw

+

=>

MOTOR

screw

off

screw off

cable

contact

distance bolt

MOTOR

TMCM-013

screw distance bolt

MOTOR

TMCM-013

Figure 8.1: Assembly of parts

We recommend a minimum distance between the TMCM-013 and motor of 5mm. The module can be directly

attached to the motor back bell with an electrical insulation spacer. Appropriate cooling might be necessary

if the motor itself gets very hot.

8.2

Motor

Attention:

-

Do not connect or disconnect the motor while power on. Damage to the module may occur.

-

Attention: A too high motor current setting can damage you motor! If in doubt, start with a low current

setting and check motor temperature. If the motor heats up very quickly, check all settings. The motor

shall never reach a temperature above 100°C under any circumstances. Some stepper motors need

contact to metallic parts to allow continuous operation. Mind the default settings when you operate in

step/dir mode the first time. You can store your own settings in the module permanently.

8.2.1

Motor choice

Care has to be taken concerning the selection of motor and supply voltage. In the different chopper modes

different criteria apply. Modes 0 and 1 are quite insensitive to the motor choice, while Mode 2 is very

sensitive, because it uses a different motor current regulation scheme. This chapter gives some

mathematical information on the motor choice, but you can skip it if you want to experiment with a given

motor. Normally, best results will be achieved when operating the given motor in a range of 50 to 100% of

nominal motor current (see motor data sheet). Mode 2 and mode 1 are mainly intended for slow, smooth