Version 3.2

Page: 56

Troubleshooting

When debugging a newly built amp the first things to do are check the wiring, make sure the correct

components are installed, and look for bad solder joints.

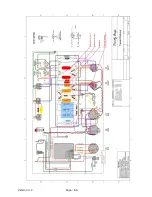

Use a voltmeter to check voltages and compare them with the voltages listed on the schematic.

Remember that you can calculate current by measuring the voltage drop across a resistor and dividing

by the resistance.

An incorrect voltage or unusual current may give you a clue to the source of the problem. A low

voltage often indicates that something is drawing more current than the power supply can handle and

dragging down the voltage.

Probing with a non-conductive object such as a chopstick while the amp is powered on is a good way

to find bad connections or problems with the way the wiring is laid out.

Remember that dangerous voltages are present when the amp is powered on. Always drain the filter

caps and disconnect the mains before working on the amp. To learn how to do this safely, see the

following ‘Faulty power supply filter caps’ discussion.

Never operate the amp without a load or you will damage the output transformer. You can use an 8

ohm 15 watt power resistor as a dummy load in place of a speaker.

Hum

Hum is the most common problem and is usually caused by AC line noise leaking into the filament

wiring or input stages and getting amplified. Here we provide a comprehensive step-by-step

troubleshooting guide.

First, measure the resistance from each parts ground connection to the chassis. All readings should be

less than 1 ohm, typically 0.5 ohms.

Make sure the Mains ground at the chassis is

very

tight.

Volume Test

A good way to troubleshoot is to divide and conquer by turning the volume control(s). If the hum

changes levels as you do this, then the source of the hum is something that affects the stages of the amp

before the volume control. A faulty, humming preamp tube can be isolated this way very quickly.

Conversely, if the volume control does not affect the hum, the cause is somewhere after the volume

control.

Faulty tube

Tubes sometimes develop internal hum. Do some tube swapping to locate the problem. Use the

volume control test.

Severely unmatched output tubes in a push pull amplifier

Push pull amplifiers get by with less power supply filtering because they're supposed to cancel this

ripple in the output transformer. The cancellation can be upset by output tubes that use different

amounts of bias current, allowing the hum to be heard.

Summary of Contents for Trinity Tweed Amp

Page 2: ...Version 3 2 Page 2 ...

Page 16: ......

Page 20: ...Version 3 2 Page 20 Input Jack Theory from 18watt com ...

Page 25: ...Version 3 2 Page 25 ...

Page 49: ...Version 3 2 Page 49 ...

Page 65: ...Version 3 2 Page 65 HEYBOER OT for TWEED 6L6GT CONVERSION ...

Page 66: ...Version 3 2 Page 66 ...

Page 75: ...Version 3 2 Page 75 ...

Page 76: ...Version 3 2 Page 76 ...

Page 77: ...Version 3 2 Page 77 Trinity Amps Schematics and Layouts ...