www.energyabsorption.com

Revision A May 2013

www.highwayguardrail.com

11

All rights in copyright reserved

BarrierGate

®

Repair Guidelines

Warning:

To avoid risk of serious injury proper precautions must be taken to

prevent the Gate Assemblies from rolling on slopes.

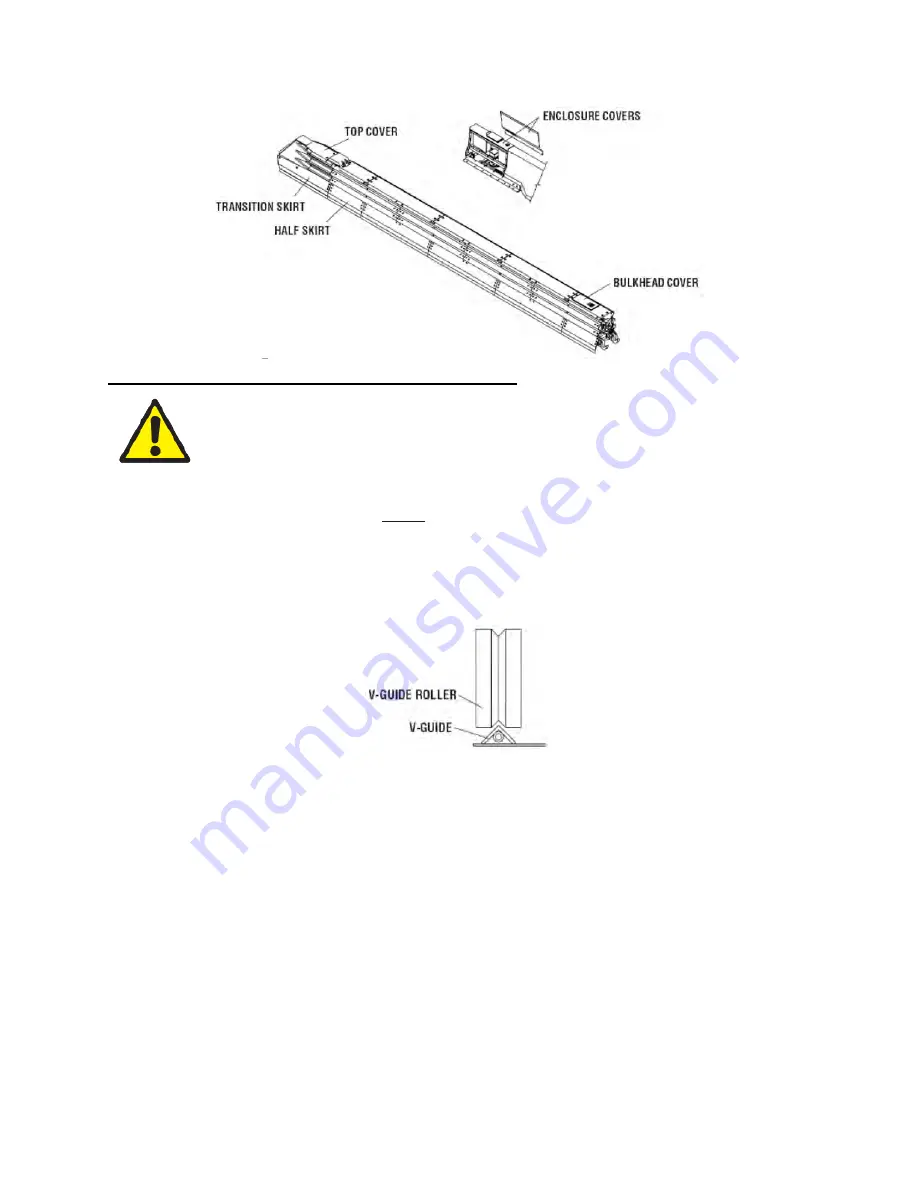

R1: Check for and remove internal obstructions to Gate movement.

Troubleshooting indicates something inside the Gate may be obstructing free opening or closing

movement. Do not operate Gate or damage to components may result. Remove Top Covers

and inspect the inside of the Gate for possible obstructions. Check for and remove excessive

debris from under the Gate. Check to make sure the V-Guide Rollers in the Bulkheads are

properly engaging the inverted angle iron Tracks and that the Transition Rollers are properly

riding on the Guide Rail. If not, reposition the Gate to bring Rollers back on track.

R2: Check and re-tension the Capstan Drive Cable.

Troubleshooting indicates that the Capstan Drive Cable is not adequately tensioned. Do not

operate gate or damage to components may result. Start by removing the appropriate Enclosure

Cover then inspect the Tension Pulley assembly. The extended length of the springs must not

exceed 330 mm (13"). If the springs exceed this length it may be due to a damaged or worn

Capstan Drive Cable or loose wire rope clamps. Inspect for and correct the cause of the loose

cable. Carry out the "Tension the Drive Cable" step in the Product Description Manual to tension

the Drive Cable.

R3: Check for and repair damaged Capstan Drive.

Troubleshooting indicate the Capstan Drive is damaged. Only the simplest Capstan Drive

repairs are likely to be made in the field. Inspect the Capstan Drive for obvious problems such

as a bound Drive Cable. If no field adjustments can be made, detach the Drive Cable and

remove the Capstan Drive for replacement.

Figure 6

Figure 5