www.energyabsorption.com

Revision B June 2013

www.highwayguardrail.com

28

All rights in copyright reserved

Maintenance

Before performing any maintenance on the SS180 TMA

®

, thoroughly read and understand the

Maintenance Section and the Safety Section of this Manual.

I. Routine Maintenance

Description

Interval

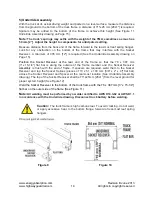

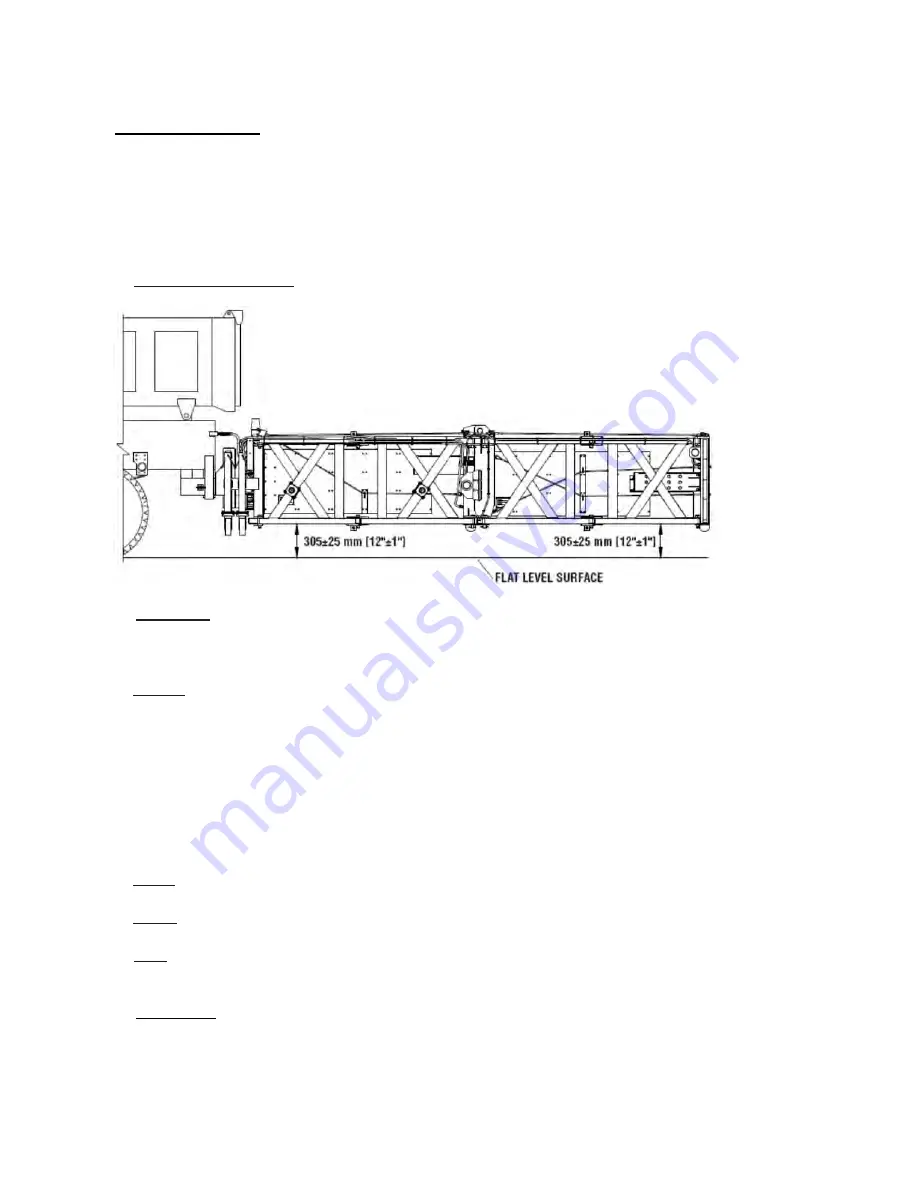

1. Height and Levelness - The height and levelness of the system is important to

its impact performance. Check regularly and adjust as necessary (See Figure 23).

A/R

Figure 23

2.

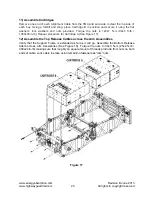

Fasteners - Check the tightness of the fasteners. See the drawings for the

locations of the fasteners. Be sure to check bolts attaching the cartridges to the

support structure. Lock washers shall be fully compressed.

1 month

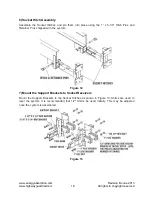

3.

Cables – (System unfolded)

A.

Cartridge Support Cables - The spring length shall be

32mm ± 2mm [1

1/4" ± 1/16] (See Figure 19 on Page 22).

B.

Alignment Cables - Crossing cables are of equal length

±

5mm (3/16") and

de

fl

ect 38-50mm [1 1/2-2"]

(See Page 21).

C.

Release Cables

- Torqued to 34±3 N-m (25 ft-lb (-0, +2)] (See Page 19).

1

st

day,

1

st

week

,

then

1 month

4.

Jacks - Check the condition of the wheels on the Jacks.

1 month

5.

Lights - Replace the light bulbs.

A/R

6

. Pins - Check all pins to make sure they are held in position by a retaining pin

as intended.

Each use

7. Lubrication - Lubricate as described in the Lubrication Section (Maintenance

Section - III) of the Manual.

Varies –

see

section