Herricane CS

®

Series

A p p l i c a t i o n G u i d e

4

www.trioniaq.com

SECTION II SYSTEM OVERVIEW

Why Choose the CS Series?

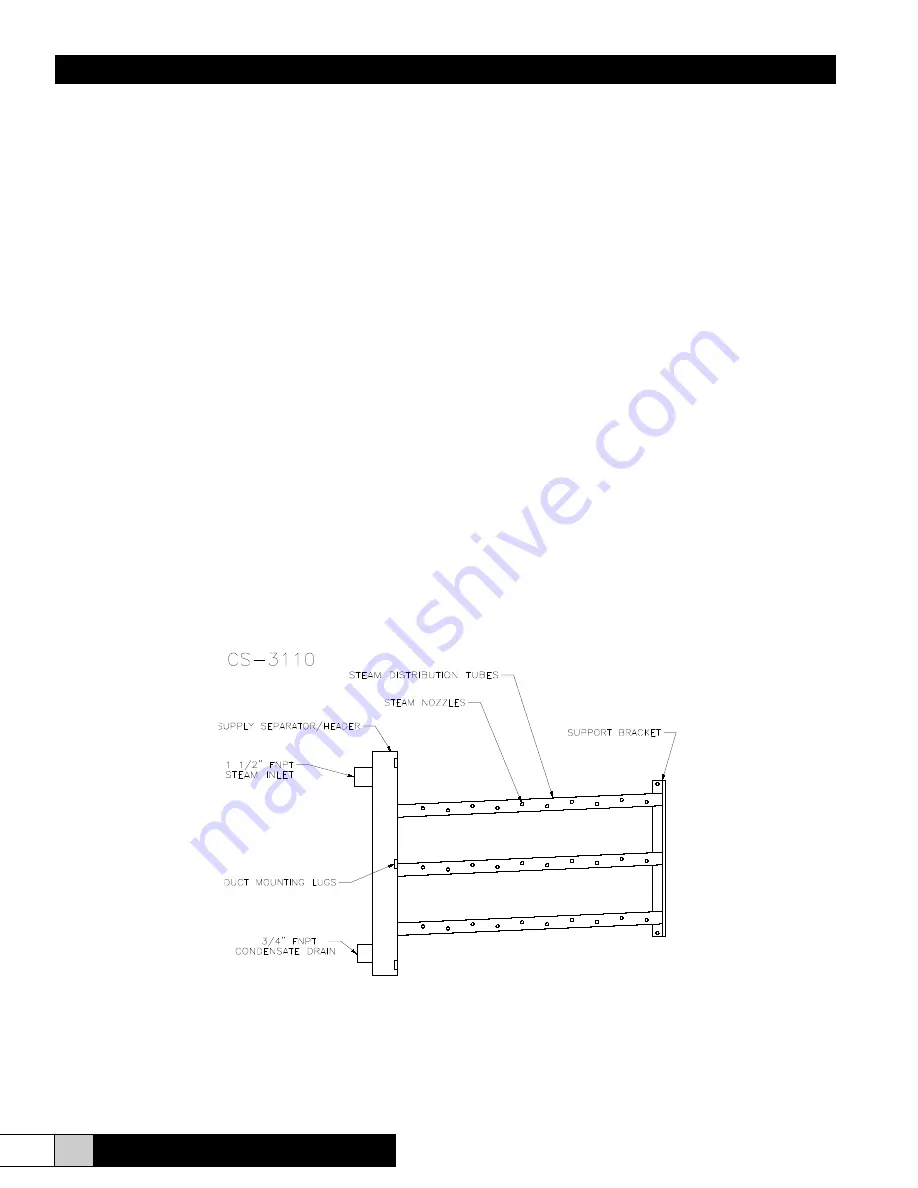

The CS-Series offers a family of four different products custom sized to handle all of your steam distribution needs. The

distribution system design has the following features that customers and engineers have told us they desire;

• Zero Maintenance

•

Quality Construction - All Stainless Steel, ASME Certified Welds

• Quality Control - Your unit has been operated prior to shipment

•

Flexible Design - Works with pressurized boiler, atmospheric boiler, or unfired boiler

• Capacity to 2000 lbs/hr

•

Stainless Steel Precision Nozzles

•

Available “Guaranteed Evaporative Distance” Performance Guarantee

• Quiet Operation

•

Superb Energy Efficiency

• NO FIELD ASSEMBLY of distribution system

•

Total system design assures that YOU GET THE CAPACITY YOU PAID FOR!

The system is as ingenious as it is simple. In a system with steam supplied be a central boiler, steam flow from the source first

passes the inlet strainer. From here the steam travels to a condensation trap, and on to the steam valve. Depending on the

application, this valve could have a solenoid operator, a pneumatic operator, or an electric operator. Once the steam passed

through the steam valve, or enters the steam distribution system. The steam distribution system utilizes the same nozzle

design as the original CS-1. This design is extremely quiet, up to 7.3 times quieter than the competition, and efficient, 3-23%

more efficient than jacketed designs, depending on the duty cycle. Any condensate that forms in the distribution system will

be disposed of through the manifold trap.

With a self-generating steam unit, the modulation of steam would occur in the boiler itself, therefore, the strainer, steam valve

and supply trap would be eliminated (See page 24).