7

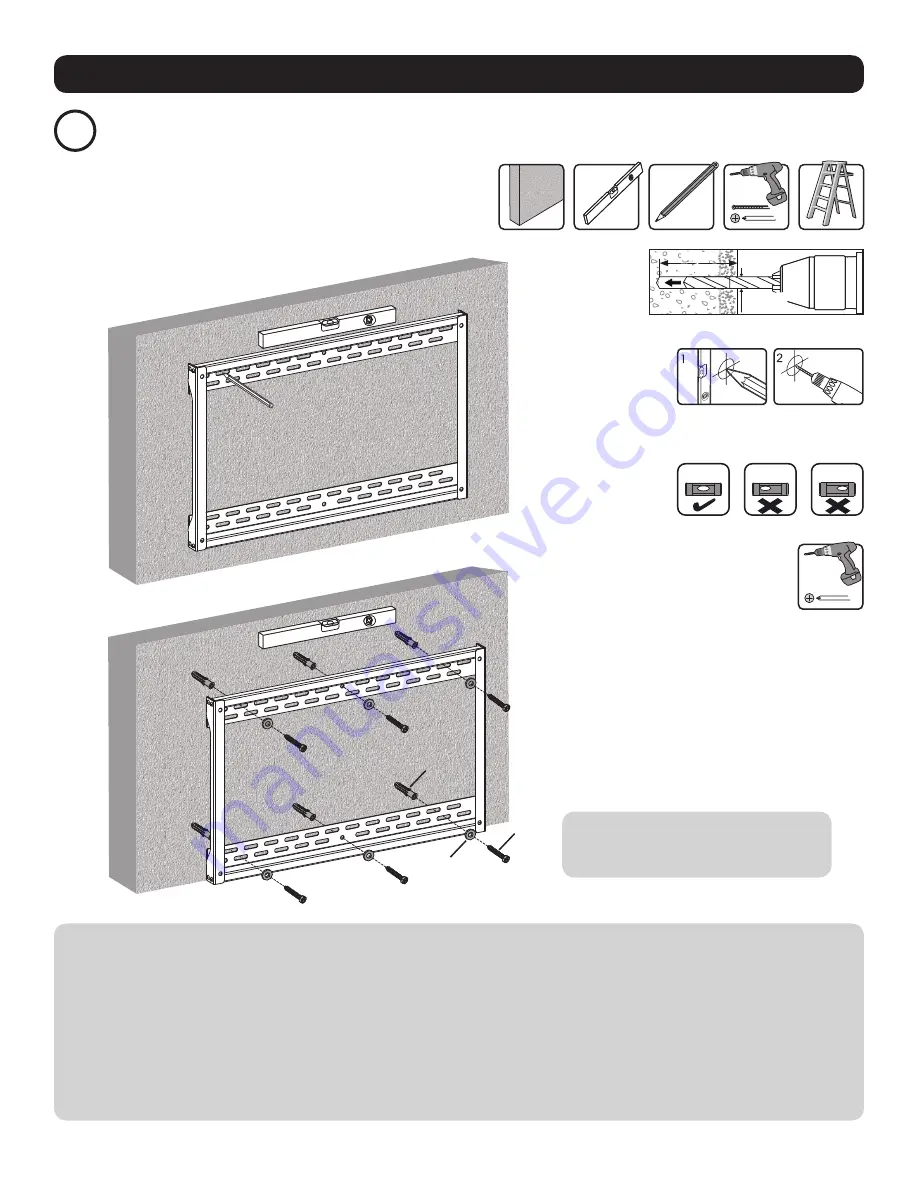

Assembly

2b

Mount on Solid Brick or Concrete Block Wall

W-B

W-A

W-C

60 mm

(2.4 in.)

O/10 mm

O/(3/8 in.)

Mark the exact

location of

mounting holes

Drill pilot

holes

Screw the

wall plate

onto the

wall

Using the ST6.3x55 screws (

W-A

), D6

washers (

W-C

) and concrete anchors (

W-B

),

attach wall plate assembly to the wall.

WARNING

• When installing wall mounts onto a concrete masonry unit (also known as a CMU or “cinder block”), verify that the actual

concrete thickness is at least 35 mm (1-3/8”) in order to hold the concrete anchors. DO NOT DRILL INTO MORTAR JOINTS!

Be sure to mount the assembled wall-mount plate with the included concrete anchors, washers and anchor bolts onto solid

sections of the blocks.

The solid sections can generally be found 25 mm (1”) toward the middle of the block from either end. An electric drill on a

slow setting is suggested to drill the hole rather than a hammer drill so as to avoid breaking out the back of the hole when

entering a hollow section.

• Installers must verify that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.