3

that is provided.

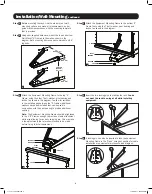

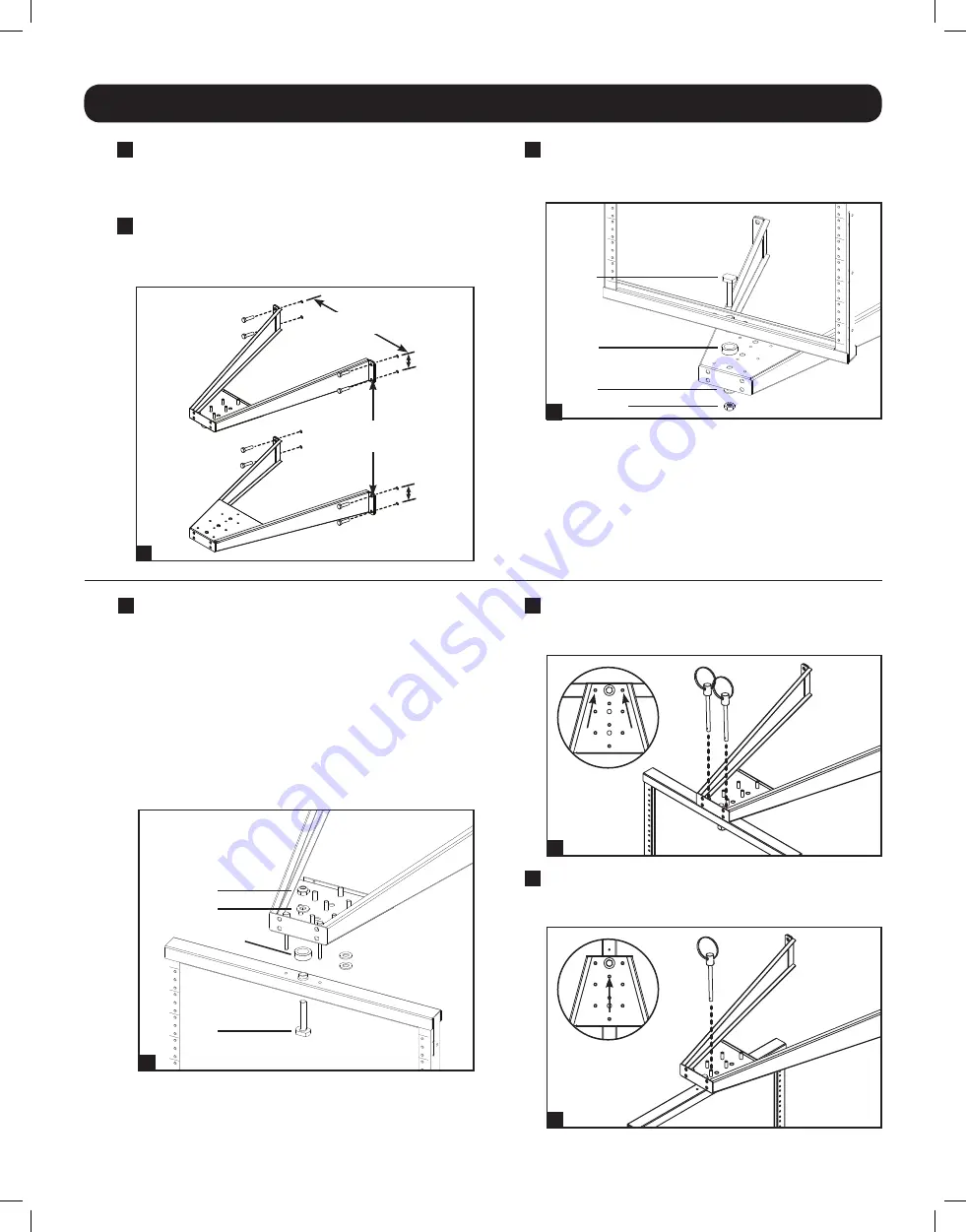

Step

2

Using user-supplied hardware, mount the top and bottom

Wall-Mount “A” Frames to the wall as shown in the

diagram. Both mounting frames can accommodate 5/16”

lag bolts.

Step

3

Attach the Equipment Mounting Frame to the bottom “A”

Frame first, using the T bolt, washer, pivot bearing and

locknut as shown in the diagram.

Step

1

Before mounting the rack, find the studs in your wall/

mounting surface and make all measurements, and or

guide marks in accordance with the mounting template

Step

4

Attach the Equipment Mounting Frame to the top “A”

Frame, using the other T bolt, washer, pivot bearing and

locknut as shown in the diagram. To allow for variation

in the installed gap between the “A” Frames, additional

washers have been included that can be used in

conjunction with the pivot bearing to provide additional

spacing.

Note:

The Equipment Mounting Frame should be tightened

to the 2 “A” Frames enough to provide a stable attachment

while also allowing for an easy swinging arc. This may take

a few adjustments that are recommended to be made

before trying to install equipment.

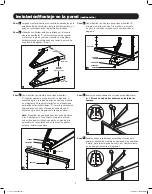

Step

5

Insert the two locking pins to stabilize the rack.

You do

not want the rack to swing at all while installing

equipment.

Step

6

A locking pin can also be inserted to lock the Equipment

Mounting Frame in the “Open” swing out position for cable

installation or equipment maintenance (see diagram).

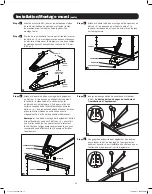

Installation/Wall-Mounting

continued

2.2”

(56.2 mm)

2.2”

(56.2 mm)

2

4

3

LOCKNUT

LOCKNUT

WASHER

WASHER

T bolt

T bolt

PIVOT

BEARING

PIVOT

BEARING

(Optional)

16”

(406.4 mm)

25.8125”

(656 mm)

(hole to hole)

5

6

17-11-211 93-2993.indb 3

11/29/2017 10:16:46 AM