Pressure Relief Procedure

The sprayer’s pressure must be manually relieved to prevent sprayer from starting or spraying

accidentally.

Fluid under high pressure can be injected through skin and cause serious injury. To reduce risk

of injury from injection, splashing fluid, or moving parts,

Follow the

Pressure Relief Procedure

whenever you:

• are instructed to relieve pressure

• stop spraying

• check or service any system equipment

• install or clean spray tip

Turn pressure control knob counterclockwise to stop.

2. Turn sprayer off.

3. Unplug power supply cord.

4. Hold metal part of gun firmly to grounded metal container. Trigger gun to relieve pressure.

5. Lock gun safety latch.

6. Open prime valve. Leave prime valve open until ready to spray again.

NOTE:

Do not store unit for extended periods of time with the Pressure relief valve open. Store

the unit in the spray position.

NOTE:

If suspected that spray tip or hose is completely clogged, or that pressure has not been

fully relieved after following steps above,

SLOWLY

loosen tip guard or hose end coupling to relieve pressure gradually, and then loosen

completely. Clear tip or hose obstruction.

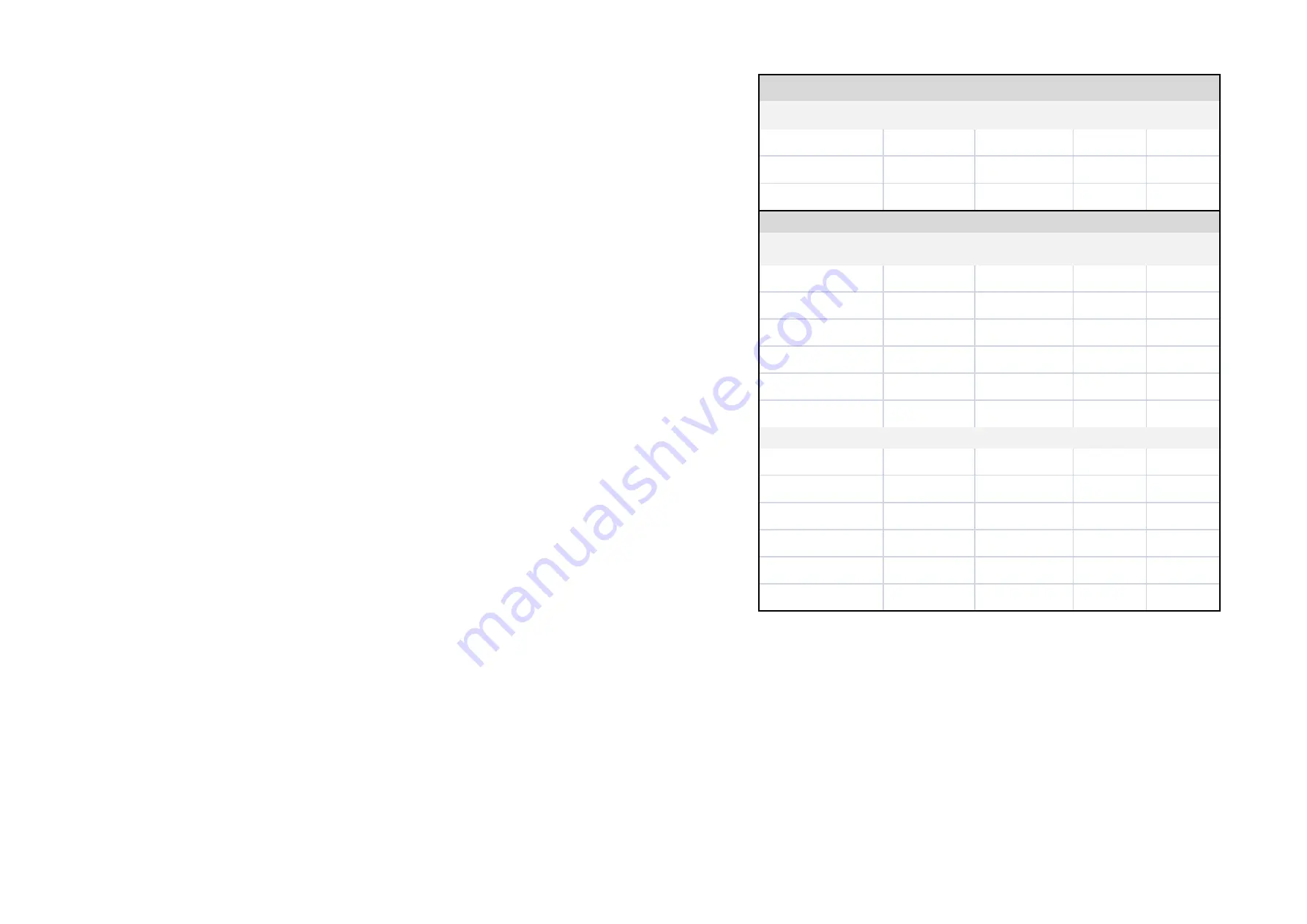

120V

15 AMP

100'

200'

300'

14 AWG

110.6

101.2

91.8

12 AWG

114.1

108.1

102.2

10 AWG

116.3

112.5

108.8

HORIZONTAL

50'

3300PSI

227 BAR

3150

217 BAR

100'

3300PSI

227 BAR

3100

213 BAR

150'

3300PSI

227 BAR

3050

210 BAR

200'

3300PSI

227 BAR

3000

207 BAR

250'

3300PSI

227 BAR

2950

203 BAR

300'

3300PSI

227 BAR

2900

199 BAR

VERTICLE

50'

3200

220 BAR

3135

216 BAR

100'

3200

220 BAR

3070

211 BAR

150'

3200

220 BAR

3005

209 BAR

200'

3200

220 BAR

2940

202 BAR

250'

3200

220 BAR

2875

198 BAR

300'

3200

220 BAR

2810

193 BAR

EXTENSION CORD VOLTAGE DROP

LINE LOSS 1/4" HOSE STANDARD LATEX PAINT

AT PUMP

AT TIP

Summary of Contents for 200-517

Page 6: ......