9

ELECTRICAL SHOCK WARNING

To reduce risk of serious injury, including electric shock, do not touch moving or electrical parts with fingers or

tools while tes�ng repair. Shut off and unplug sprayer when inspec�on is complete. Install all covers, guards,

gaskets, screws and washers before opera�ng sprayer.

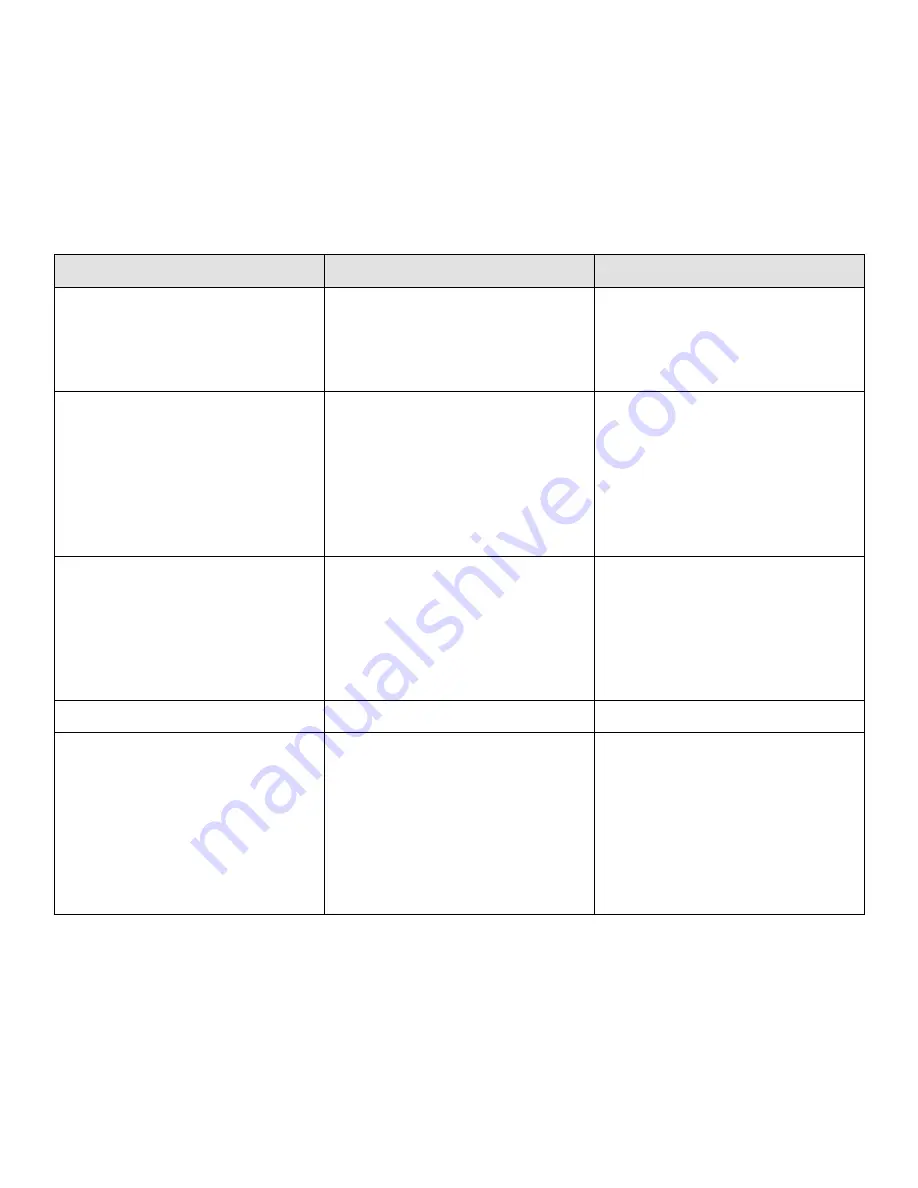

PROBLEM

WHAT TO CHECK

REMEDY

MOTOR WILL NOT TURN ON

1 - Unit is not plugged in.

2 - Pressure is set too low.

3 - The circuit breaker is open.

1 - Plug the unit in.

2 - Increase pressure.

3 - Check the breaker and reset if

needed.

UNIT WILL NOT PRIME

1 - Suction hose is loose.

2 - Suction filter is clogged.

3 - Inlet ball is stuck.

4 - Outlet ball is stuck.

1 - Check the o-rings and tighten the

suction hose.

2 - Clean or replace the suction filter

3 - Remove the suction hose and

move the inlet ball with the eraser end

of a pencil.

4 - Remove the suction hose and the

inlet valve. Move the outlet ball with

the eraser end of a pencil.

PUMP BUILDS PRESSURE BUT

WILL NOT SHUT OFF

1 - The inlet ball or seat are obstructed

or chipped.

2 - Outlet ball or seat are

obstructed or chipped.

3 - Prime valve is leaking.

1 - Clean or replace if needed.

2 - Clean or replace if needed.

3 - Replace the prime valve if coating

leaks while under pressure.

PAINT LEAKING FROM WET CUP

1 - Inspect upper packing.

1 - Replace upper packing if needed.

PUMP OUTPUT IS LOW

1 - The spray tip could be worn.

2 - The inlet or outlet balls are worn.

3 - Prime valve is worn.

1 - Inspect the tip by checking the fan

pattern width. If worn, replace.

2 - Inspect the inlet and outlet balls for

damage. Replace if worn.

3 - If the prime valve leaks while

spraying, clean or replace is worn.

NOTE:

Before performing and inspection or repair, make sure to follow the pressure relief

Procedure. Never attempt to do any service while the unit is plugged in or under pressure.

Summary of Contents for 600-830

Page 58: ...58 NOTES ...

Page 59: ...59 NOTES ...