Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 50

9.1.

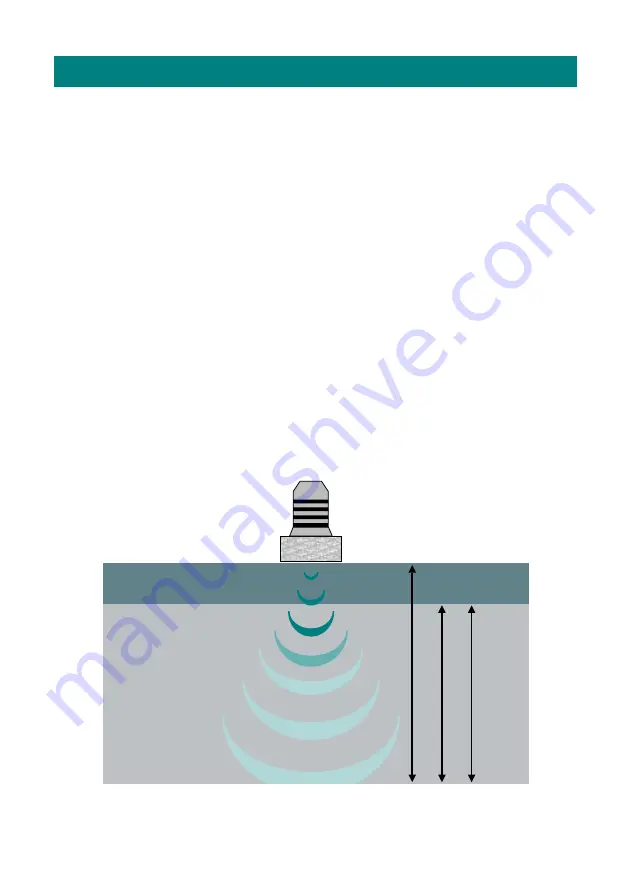

How Multiple Echo Works

All Ultrasonic Thickness Gauges should be calibrated to the velocity of sound

of the material being measured. Coatings have a different velocity of sound

than metal and it is important they are not included in the measurement.

Multiple echo ensures all coatings are completely eliminated from the

measurement.

How it works:

A transmitted ultrasound pulse travels though both the coating and the metal

and reflects from the back wall. The returned echo then reverberates within the

metal, with only a small portion of the echo travelling back through the coating

each time. The timing between the small echoes gives us the timing of the

echoes within the metal, which relate to the metal thickness. The returned

echoes need not be consecutive as the gauge will interpret them automatically

and calculate the thickness. A minimum of three echoes is checked each time.

This is referred to as the

Automatic Measurement Verification System

(AMVS)

.

T

im

in

g

1

T

im

in

g

3

T

im

in

g

2

Probe

Coating

Metal

9. Using the Multigauge 5700