16

Electric shower

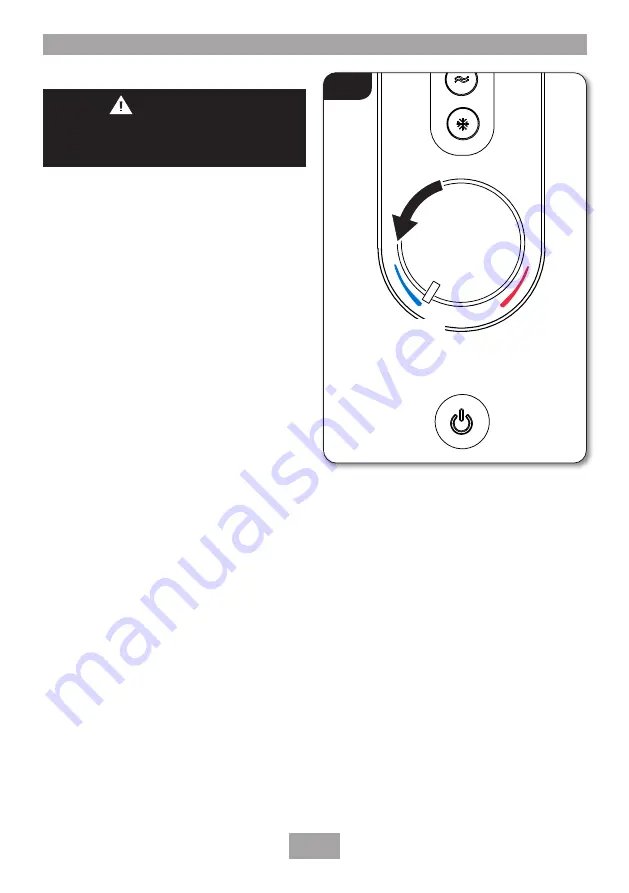

Fig.16

Temperature flow

control at maximun

flow position

COMMISSIONING PROCEDURE

The first operation of the shower is intended

to flush out any remaining unit debris and

to make sure the heater unit contains water

before the elements are switched on.

This operation

MUST

be carried out

WITH

the

hose screwed to the outlet but

WITHOUT THE

SHOWER HEAD ATTACHED

. Ensure the sealing

washer is in place and the outlet of the hose is

directed to waste.

IMPORTANT:

The valve spindle

(fig.13)

and

the temperature flow control

(fig.14)

MUST

be

turned fully

clockwise to the minimum flow

position - failure to do this could cause

the PRD to operate.

Ensure the water supply to the shower is turned

on at the isolating stopvalve.

Switch on the electricity supply to the shower at

the isolating switch.

Once water starts to flow from the hose,

slowly rotate the temperature control fully

anti-clockwise to the maximum flow position

(fig.16)

.

It will take about thirty seconds for a smooth

flow of water to be obtained while air and any

debris is being flushed from the shower

When a smooth flow of water is obtained, turn

the temperature flow control from maximum to

minimum flow and back again several times to

release any trapped air within the unit.

Once the flushing out has been completed,

switch off the electricity to the shower at the

isolating switch. The water will cease to flow.

Unscrew the top and bottom cover retaining

screws and lift the cover from the backplate.

NOTE:

The screws do not need to be completely

removed to be able to remove the cover.

WARNING

Before normal operation of the shower, it

is essential the following commissioning

procedure is completed correctly.

Summary of Contents for 10.5kW

Page 25: ...25 Electric shower ...

Page 26: ...26 Electric shower ...

Page 27: ...27 Electric shower ...