6

GB

Step 1:

Fit the Outer Bearings (H) to the Sliding Insert (A)

using the M6 x 20 Screws (I) and M6 Hex Nuts

(J) as shown. Ensure they are fitted on the same

side of the slider as the three small holes. Fit the

Inner Bearings (K) to the Sliding Insert using the

M6 x 45 Screws (L) and M6 Flange Nuts (M). Do

not yet tighten. All bearings should be parallel to

the sides of the sliding insert.

Fit the Bosses (O) from underneath the two

central holes in the sliding insert and attach the

Main Body (B) to the sliding insert by tightening

the M6 x 30 Hex Bolts (P) and Washers (Q)

through the captive nuts in the main body.

Loosen off the depth stop screws on the

underneath of the sliding insert to allow

approximately 29mm movement of the spring-

loaded plunger. (Fig.4)

Step 2:

Slide the zinc locking pin on the underside of the

main body to the central 'lock' position.

Fit the sliding insert into the router table tracks

by locating the slots on the inner bearings onto

the flange on the aluminium inner track. Now

firmly tighten the inner bearing screws and

check that the sliding insert slides smoothly. If

there is any float between the aluminium inner

track and the inner bearings, loosen the screws,

twist the bearing slightly and re-tighten.

The lock pin on the main body should locate

in the slot on the router plate.

In use:

When

a safety guard is depressed the lock pin is

released, allowing the fence to slide in the

direction the guard is depressed. The fence will

automatically spring back to its central position.

Note:

If the fence does not freely spring back,

loosen the fit of the inner bearings against the

aluminium track, or spray the track with spray

lubricant.

Screw the Inner Clamp Knobs (N) onto the inner

bearing screws, they cut their own thread.

In use:

When fitting or removing the sliding

insert the cut-away edges of the clamps must

face toward the inner track. During operation

turn the cut-away edges away from the inner

track. Do not over-tighten, the sliding insert

should be held down yet free to slide.

Check that the biscuit joiner is level with or

slightly above the table surface and if necessary

to remove it and adjust the height of the

aluminum inner track on the router table

Step 3:

Remove the Biscuit Joiner Cutter (C) from its

storage position in the end of the main body.

If you have a

1

⁄

4

" router, remove the

1

⁄

4

" Shank

(D) from its storage position in the end of the

main body. If tight, gently prise it out using a

screwdriver. Unbolt the cutting disc from the

1

⁄

2

"

shank and refit it to the

1

⁄

4

" shank. Do not over-

tighten. Store the unused

1

⁄

2

" shank in place of

the

1

⁄

4

" shank in the end of the main body.

Remove the biscuit joiner from the table. Fit the

large insert ring, supplied with the router table,

to the router plate. Tighten the cutter firmly into

the router collet.

Adjust the cutter height so that there is 5-7mm

clearance between the underside of the cutter

and the router plate. Make sure the router's

height adjustment is securely locked before use.

Step 4:

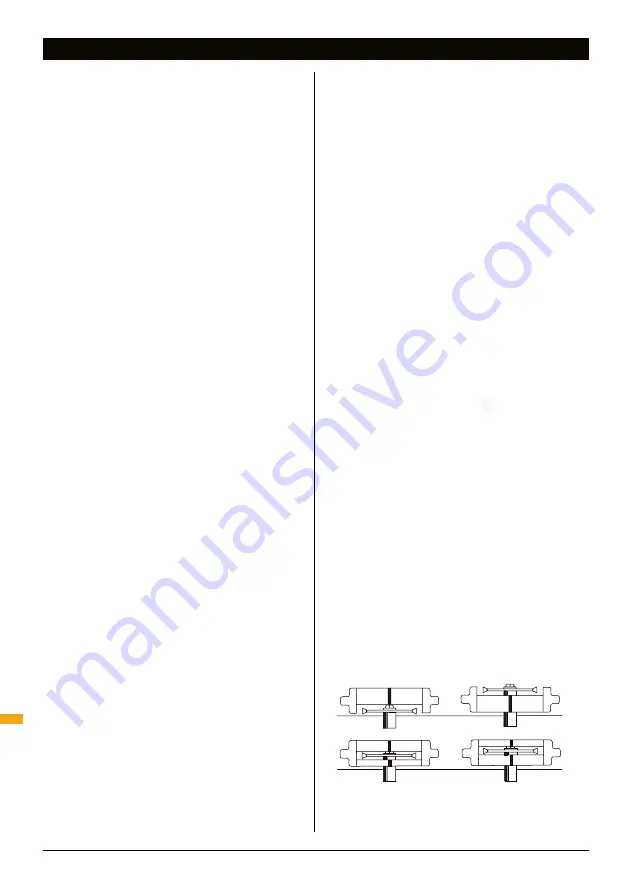

Familiarise yourself with the Notched and Slotted

Windows (E & F). They reduce the risk of finger

entry into the cutter zone and improve saw dust

extraction. The windows are reversible so that

the two sets cover the full range of cutter height

adjustment from 5-25mm above the table.

The cutter should never be set any higher than

25mm above the router plate. (Fig.1)

To remove the windows push outwards, from the

inside, near each side of the window.

When re-fitting, use the safety guards to push

them fully home. Store the unused pair of

windows in the holes provided on the sliding

guide.

Assembly

ASSEMBLY

5 - 10

10 - 15

15 - 20

10 - 15

15 - 20

20 - 25

20 - 25

5 - 10

Fig.1