26

FAULT FINDING/TROUBLESHOOTING

FAULT FINDING

Important:

Switch off the electricity at the mains supply and remove the circuit fuse before

attempting any fault finding inside the unit.

Problem/Symptom Cause

Action/Cure

5

During use, the water

flow ceases abruptly.

5.1

Interrupted power

supply.

5.1.1

See 1.1.1 and 1.1.2.

5.2

Solenoid valve

malfunction (pump

still operates).

5.2.1

Switch off immediately. Have solenoid checked

by a competent electrician or contact Customer

Service.

5.3

Pump motor faulty.

5.3.1

See 1.3.1.

6

Shower performance

drops, indicated by a

gradual reduction in

water flow.

6.1

Water starvation to

the unit.

6.1.1

Check the filter is not blocked. First, isolate the

electricity supply and then remove the cover.

6.1.2

Check the cold water cistern is full.

6.1.3

Make sure the water supply pipe is not blocked

or air locked.

6.1.4

Check there is no simultaneous demand from

the cistern during showering.

6.1.5

Reprime the unit without electricity switched on

to the unit (see ‘commissioning’).

7

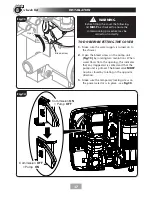

Pressure relief device

has operated (water

ejected from the PRD).

7.1

Blocked showerhead.

7.1.1

Clean or replace blocked showerhead and then

fit a new PRD.

7.2

Twisted/blocked

flexible shower hose.

7.2.1

Check for free passage through the hose.

Replace the hose if necessary & then fit a new PRD.

7.3

Showerhead not

removed while

commissioning.

7.3.1

Fit a new PRD. Commission the unit with

showerhead removed.

8

Shower fails to shut

off when STOP

button is pressed.

8.1

START/STOP button

failure.

8.1.1

Isolate from electricity supply and call

Triton customer services.

Problem/Symptom

Cause

Action/Cure

NOTE:

Identify cause of operation before fitting new PRD unit.

When fitting a new PRD, follow the commissioning procedure.

It is advised all electrical maintenance/repairs to the shower

should be carried out by a suitably qualified person.

In the unlikely event of a fault occurring please contact Triton Customer Service.

DO NOT remove the shower from the installation.

Summary of Contents for T90SR

Page 27: ...27 SPARE PARTS 10 7 6 5 4 1 3 8 2 13 11 9 16 1 9 12 6 8 2 4 7 13 3 10 5 14 14 15 17 11 12 ...

Page 30: ...30 ...

Page 31: ...31 ...