10

GB

Troubleshooting

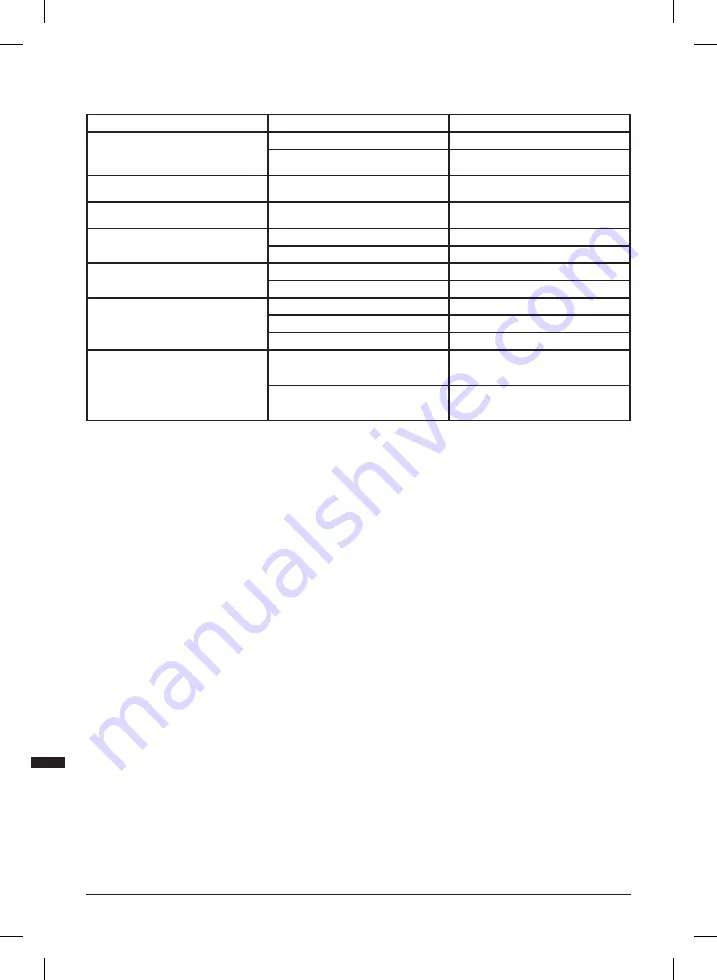

Problem

Possible cause

Solution

No function when ON/OFF Switch (2) is operated

No power

Check power supply

Defective ON/OFF Switch

Have the ON/OFF Switch replaced by an authorised

Triton service centre

Motor suffers from cut-outs, loss of performance and

produces sparks and/or burning smells

Carbon brushes worn

Have the brushes replaced by an authorised

Triton service centre

No sanding action when ON/OFF Switch (2) is operated,

despite the motor running

Gears not engaged

Consult a Triton service centre

Slow material removal

Sanding Sleeve (9) too fine or worn

Fit new Sanding Sleeve with coarser grit

Tool speed set too low

Increase tool speed

Scratches on workpiece after sanding

Sanding Sleeve too coarse

Fit new Sanding Sleeve with finer grit

Not enough material removed

Continue sanding

Burn marks on workpiece

Sanding Sleeve incompatible with material

Fit correct Sanding Sleeve

Tool speed set too high

Decrease tool speed

Too much pressure exerted on to the sander

Use less pressure whilst moving the machine

Excessive dust emission

Vacuum dust extraction system not connected, or extraction

system not switched on

Check connection of the vacuum hose, the Dust Extraction

Port Adaptor (7) (if used) and ensure dust extraction system

is switched on

Dust extraction not working; dust extraction blocked

Check dust extraction system; unblock dust extraction

(see ‘Cleaning the dust extraction port’.) Consult a Triton

service centre if problems persist

825289_Manual.indd 10

22/10/2018 12:54

Summary of Contents for TSPSP650

Page 2: ...2 8 9 10 1 2 3 4 7 11 13 12 5 6 825289_Manual indd 2 22 10 2018 12 54...

Page 3: ...3 5 14 13 16 17 15 18 7 825289_Manual indd 3 22 10 2018 12 54...

Page 4: ...4 H C A B D E F G 825289_Manual indd 4 22 10 2018 12 54...

Page 5: ...5 I J Fig I Fig II 16 17 5 5 825289_Manual indd 5 22 10 2018 12 54...