3NB/3ND/3N0/3NK-2

1-4-29

DF intermediate sen-

sor retention jam

(J631X)

DF main tray ejection

retention JAM (J641X)

DF eject sensor non

arrival jam (J6500)

DF eject sensor reten-

tion jam (J651X)

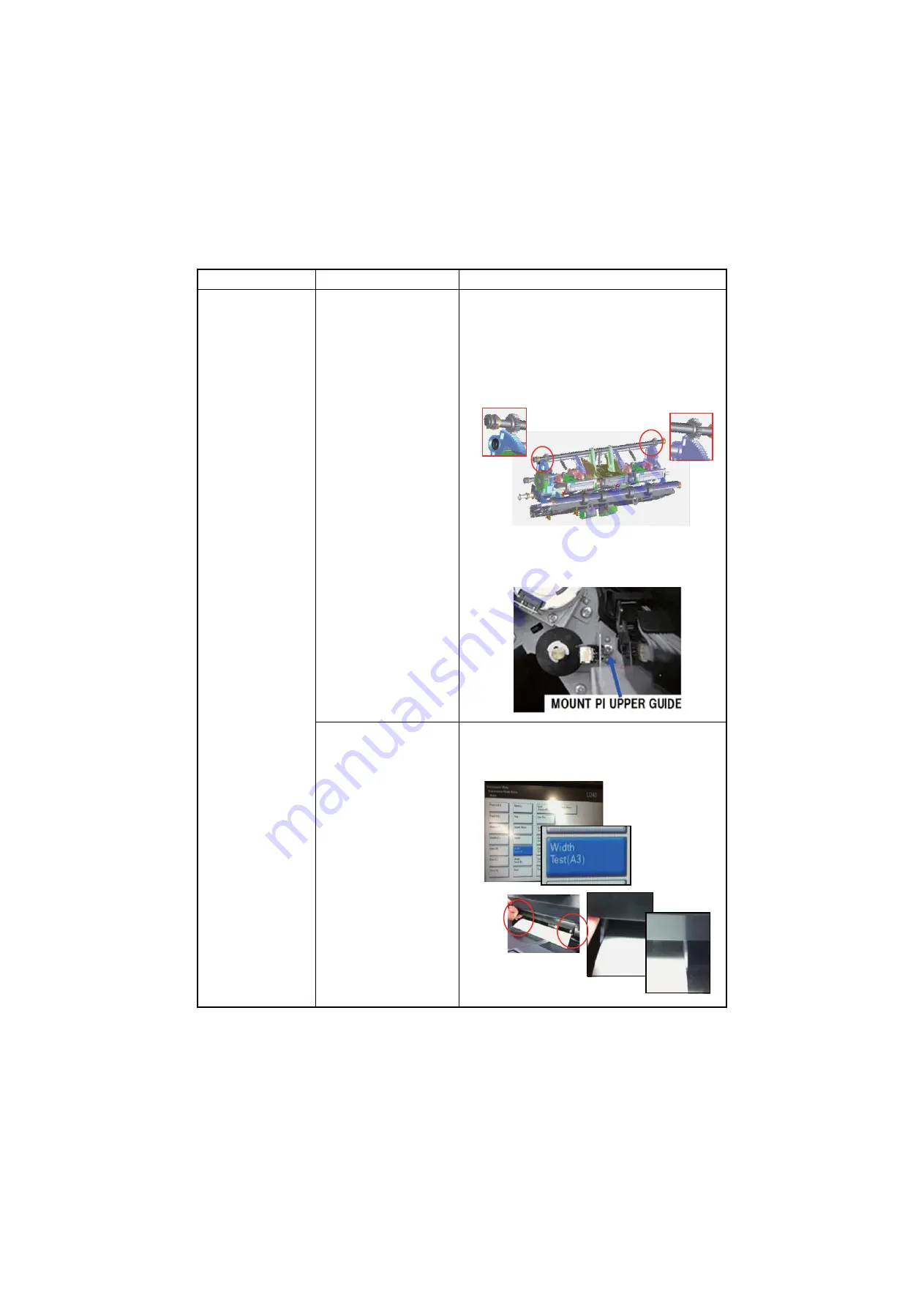

2. Check the range of the

up and down

movement of the

ejection rollers.

Check if the operating

position after feeding in

the first sheet is normal.

(1)If it moves askew (due to

the forward and backward

shift of phase on the eject

guide).

(2)If the range of motion is

too small.

Check if the gap between

the ejection roller and the

ejection pulleys is approxi-

mately 3.5 - 5.5 mm.

(Check gaps while making

paper still in the intermedi-

ate process tray.)

If the gap is not correct, fix balance of the bundle

eject unit.

If (1): Correct the phase shifting with meshing of the

front and back gears.

(Turn on U240 - Motor-EjectUnlock (30) to check the

balance of the front and back rollers with the bundle

eject unit opened.)

If (2): Adjust the positioning of or replace the Mount

PI Upper Guide.

3. Execute U240 Motor -

Width Test A3/LD to

adjust the position of

the width adjuster

cursor of the process

tray. Check if the cursor

is located at 0 - +0.5

from the paper edge.

Or check if the cursor is

abnormally shifted.

(The DF and the main

unit paper sources)

If the width adjuster cursor is wrongly positioned,

perform U246 Finisher - Width Front HP/Width Tail

HP.

Jam types

Check description

Corrective measures

Summary of Contents for UTAX AK 730

Page 5: ...This page is intentionally left blank ...

Page 11: ...This page is intentionally left blank ...

Page 15: ...3NB 3ND 3N0 3NK This page is intentionally left blank ...

Page 25: ...3NB 3ND 3N0 3NK 1 1 10 This page is intentionally left blank ...

Page 43: ...3NB 3ND 3N0 3NK 1 2 18 3 Remove tape and pad Figure 1 2 23 Tape Pad ...

Page 45: ...3NB 3ND 3N0 3NK 1 2 20 This page is intentionally left blank ...

Page 81: ...3NB 3ND 3N0 3NK 1 3 36 This page is intentionally left blank ...

Page 157: ...3NB 3ND 3N0 3NK 1 4 76 This page is intentionally left blank ...

Page 169: ...3NB 3ND 3N0 3NK 1 5 12 This page is intentionally left blank ...

Page 206: ...3NB 3ND 3N0 3NK 2 2 11 This page is intentionally left blank ...

Page 246: ...1 1 INSTALLATION GUIDE INSTALLATION GUIDE FOR 4000 SHEETS FINISHER ...

Page 269: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT MFP A ...

Page 283: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT MFP B ...

Page 284: ...E F A H G I J B D C ...

Page 291: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT PRINTER ...

Page 295: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 312: ...INSTALLATION GUIDE FOR MULTI TRAY ...

Page 326: ...INSTALLATION GUIDE FOR MULTI TRAY ATTACHMENT KIT PRINTER ...

Page 330: ...INSTALLATION GUIDE FOR PUNCH UNIT ...