3NB/3ND/3N0/3NK

1-4-72

(25)

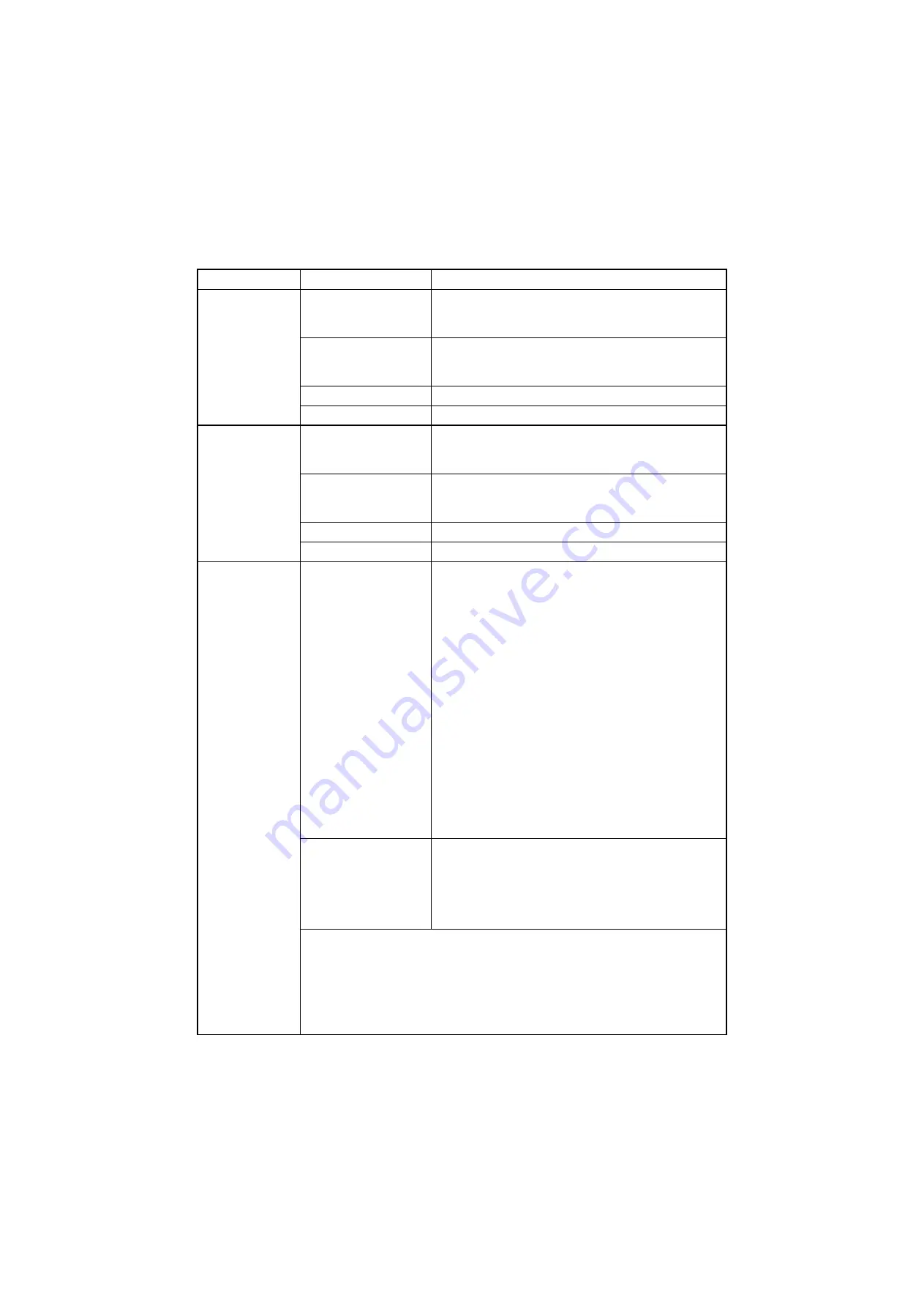

Punch motor does

not operate.

1. Defective connector

cable or poor con-

tact in the connector.

Reinsert the connector. Also check for continuity within the

connector cable. If none, replace the cable.

Punch motor and Punch PWB (YC4)

2. Defective drive trans-

mission system.

Check if the rollers and gears rotate smoothly. If not,

grease the bushes and gears. Check for broken gears and

replace if any.

3. Defective motor.

Replace the Punch motor.

4. Defective PWB.

Replace the Punch PWB and check for correct operation.

(26)

Punch slide motor

does not operate.

1. Defective connector

cable or poor con-

tact in the connector.

Reinsert the connector. Also check for continuity within the

connector cable. If none, replace the cable.

Punch slide motor and Punch PWB (YC3)

2. Defective drive trans-

mission system.

Check if the rollers and gears rotate smoothly. If not,

grease the bushes and gears. Check for broken gears and

replace if any.

3. Defective motor.

Replace the Punch slide motor.

4. Defective PWB.

Replace the Punch PWB and check for correct operation.

(27)

A paper jam is indi-

cated when the

main power switch

is turned on.

1. A piece of paper torn

from paper is caught

around sensor.

Bridge to DF

BR conveying sensor 1,2

or BR eject sensor ,DF

paper entrance sensor,

DF middle sensor, DF

eject paper sensor, DF

sub eject sensor, DF

drum sensor

Center-folding unit

CF paper conveying sen-

sor,CF paper entry sen-

sor CF eject sensor

Mail box

Tray overflow switch 1 to

7,Tray eject sensor

Check visually and remove it, if any.

2. Defective sensor.

Replace the BR conveying sensor 1,2 or BR eject sensor

,DF paper entrance sensor, DF middle sensor, DF eject

paper sensor, DF sub eject sensor, DF drum sen-

sor(Bridge,DF),CF paper conveying sensor,CF paper entry

sensor CF eject sensor(Center-folding unit),Tray overflow

switch 1 to 7 or Tray eject sensor(Mail box).

* : Bridge unit for installing with MFP only

Problem

Causes

Check procedures/corrective measures

Summary of Contents for UTAX AK 730

Page 5: ...This page is intentionally left blank ...

Page 11: ...This page is intentionally left blank ...

Page 15: ...3NB 3ND 3N0 3NK This page is intentionally left blank ...

Page 25: ...3NB 3ND 3N0 3NK 1 1 10 This page is intentionally left blank ...

Page 43: ...3NB 3ND 3N0 3NK 1 2 18 3 Remove tape and pad Figure 1 2 23 Tape Pad ...

Page 45: ...3NB 3ND 3N0 3NK 1 2 20 This page is intentionally left blank ...

Page 81: ...3NB 3ND 3N0 3NK 1 3 36 This page is intentionally left blank ...

Page 157: ...3NB 3ND 3N0 3NK 1 4 76 This page is intentionally left blank ...

Page 169: ...3NB 3ND 3N0 3NK 1 5 12 This page is intentionally left blank ...

Page 206: ...3NB 3ND 3N0 3NK 2 2 11 This page is intentionally left blank ...

Page 246: ...1 1 INSTALLATION GUIDE INSTALLATION GUIDE FOR 4000 SHEETS FINISHER ...

Page 269: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT MFP A ...

Page 283: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT MFP B ...

Page 284: ...E F A H G I J B D C ...

Page 291: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT PRINTER ...

Page 295: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 312: ...INSTALLATION GUIDE FOR MULTI TRAY ...

Page 326: ...INSTALLATION GUIDE FOR MULTI TRAY ATTACHMENT KIT PRINTER ...

Page 330: ...INSTALLATION GUIDE FOR PUNCH UNIT ...