3NB/3ND/3N0/3NK

1-4-74

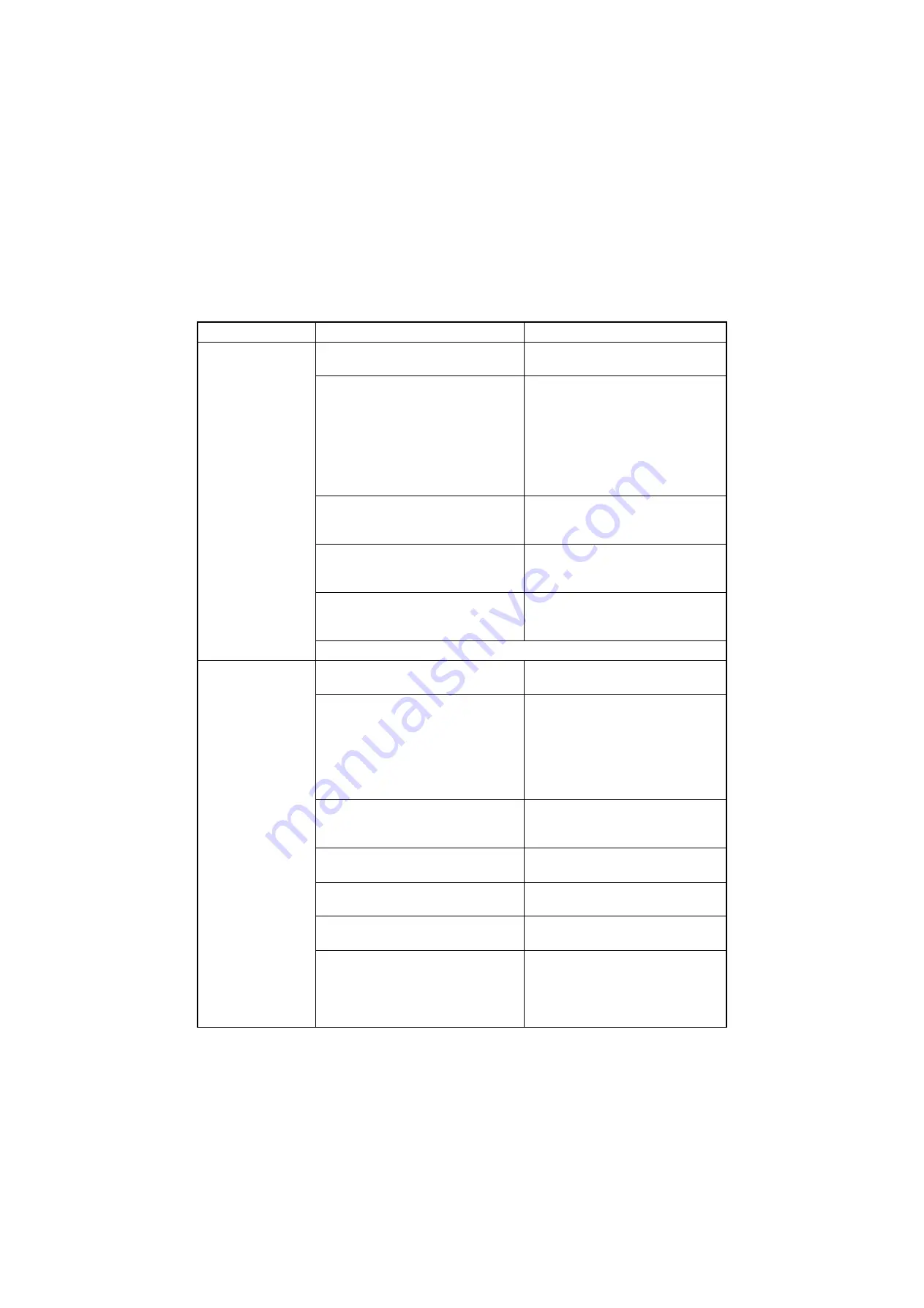

1-4-7 Mechanical problems

If the part causing the problem was not supplied, use the unit including the part for replacement.

Problem

Causes/check procedures

Corrective measures

(1)

Paper jams.

(Bridge unit)

Paper outside specifications is used.

Use only paper conforming to the speci-

fications.

Check if the surfaces of the following roll-

ers are dirty with paper powder.

BR conveying roller

BR conveying pulley

BR feedshift roller*

BR feedshift pulley*

BR eject roller 1,2

BR eject pulley 1,2*

Clean with isopropyl alcohol.

Check if the contact between the BR

conveying roller and BR conveying pulley

is correct.

Check visually and remedy if necessary.

Check if the contact between the BR

feedshift roller* and BR feedshift pulley*

is correct.

Check visually and remedy if necessary.

Check if the contact between the BR

eject roller 1,2* and BR eject pulley 1,2*

is correct.

Check visually and remedy if necessary.

* : Bridge unit for installing with MFP only

(2)

Paper jams.

(Finisher)

Paper outside specifications is used.

Use only paper conforming to the speci-

fications.

Check if the surfaces of the following roll-

ers are dirty with paper powder.

Paper entry roller,Paper entry pulley

Middle roller,Middle pulley

Main tray eject roller ,Eject pulley

Left sub tray feed roller,Feed pulley

Left sub tray eject roller,Eject pulley

Clean with isopropyl alcohol.

Check if the contact between the paper

entry roller and paper entry pulley is cor-

rect.

Check visually and remedy if necessary.

Check if the contact between the middle

roller and middle pulley is correct.

Check visually and remedy if necessary.

Check if the contact between the Main

tray eject roller and eject pulley is correct.

Check visually and remedy if necessary.

Check if the contact between the left sub

tray feed roller and feed pulley is correct.

Check visually and remedy if necessary.

Check if the contact between the Left sub

tray eject roller and eject pulley is correct.

Check visually and remedy if necessary.

Summary of Contents for UTAX AK 730

Page 5: ...This page is intentionally left blank ...

Page 11: ...This page is intentionally left blank ...

Page 15: ...3NB 3ND 3N0 3NK This page is intentionally left blank ...

Page 25: ...3NB 3ND 3N0 3NK 1 1 10 This page is intentionally left blank ...

Page 43: ...3NB 3ND 3N0 3NK 1 2 18 3 Remove tape and pad Figure 1 2 23 Tape Pad ...

Page 45: ...3NB 3ND 3N0 3NK 1 2 20 This page is intentionally left blank ...

Page 81: ...3NB 3ND 3N0 3NK 1 3 36 This page is intentionally left blank ...

Page 157: ...3NB 3ND 3N0 3NK 1 4 76 This page is intentionally left blank ...

Page 169: ...3NB 3ND 3N0 3NK 1 5 12 This page is intentionally left blank ...

Page 206: ...3NB 3ND 3N0 3NK 2 2 11 This page is intentionally left blank ...

Page 246: ...1 1 INSTALLATION GUIDE INSTALLATION GUIDE FOR 4000 SHEETS FINISHER ...

Page 269: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT MFP A ...

Page 283: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT MFP B ...

Page 284: ...E F A H G I J B D C ...

Page 291: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT PRINTER ...

Page 295: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 312: ...INSTALLATION GUIDE FOR MULTI TRAY ...

Page 326: ...INSTALLATION GUIDE FOR MULTI TRAY ATTACHMENT KIT PRINTER ...

Page 330: ...INSTALLATION GUIDE FOR PUNCH UNIT ...