SERVICE

SHEET No. 1008

(contd.)

Note that turning the plate clockwise advances and anti-clockwise retards the timing. Also remember the importance of

the contact breaker gap, for even a slight variation tends to alter the timing. (Op ening the p oints adv ances

the timing ; closing them retards the timing).

A rough check of the timing can be made by observing the position of the hexagon nuts C in the slots in the contact

breaker plate. They s hould be approximately

1

6" to the left of the centre of the slots and it will be seen that

the timing can be roughly set by slackening off the hexagons, with the nearside p iston o n top d ead centre

o f th e compr ess ion stro ke, ens ur in g th at th ey are in th e app rox imate cen tr e of the slots and then re-

tightening after turning the contact breaker plate approximately -&" to the right.

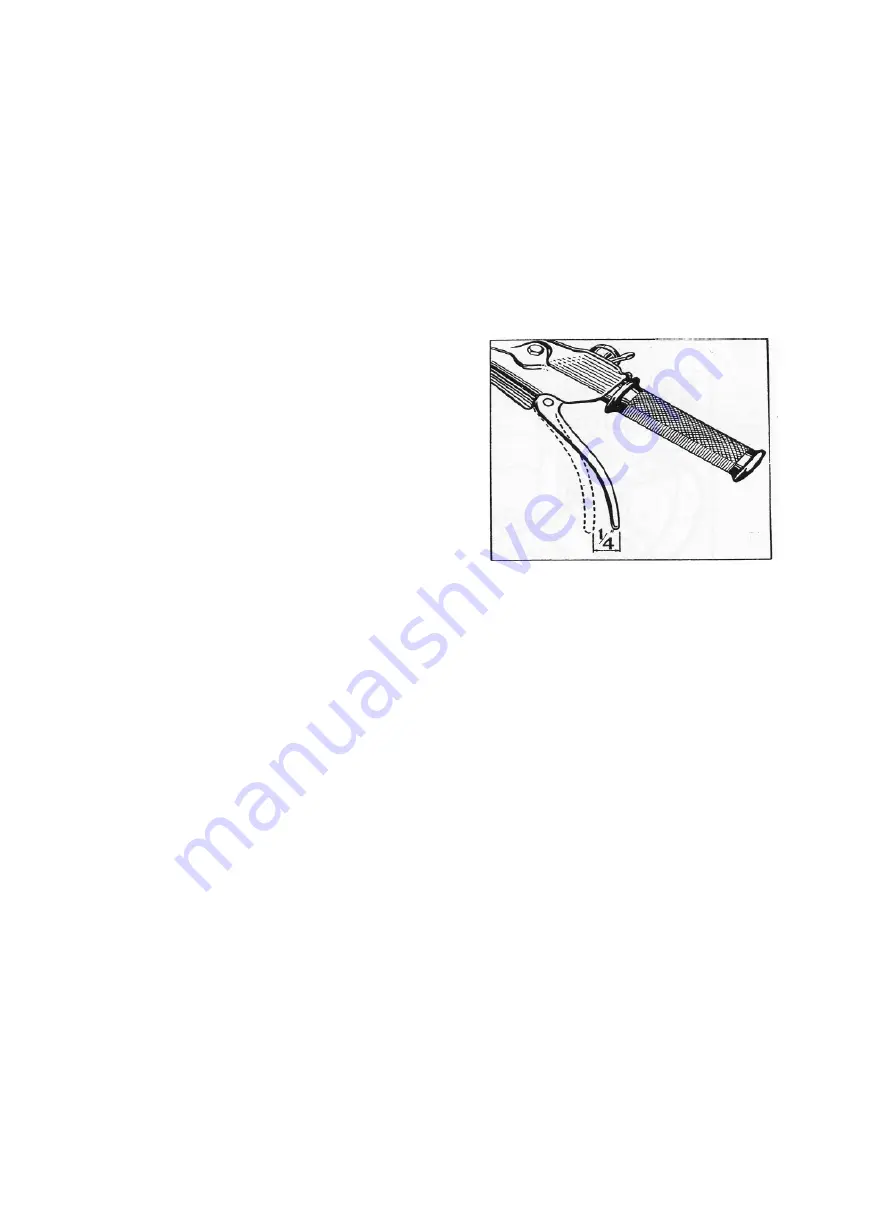

Clutch.

Should it be necessary at any time to increase the spring

tension on the clutch pressure plates, access to the spring nuts can be

obtained through the primary drive oil level and filler plug. It should,

however, be borne in mind that adjus tment of the clutch

springs should only be necessary after a very considerable

mileage or if clutch slip is occurring, and before any alteration

to the spring tension is made ascertain that the clutch cable is

correctly adjusted, as in dicated by ap pro ximately 4" of free

movement at the end of the clutch handlebar lever, as in Fig. 22. The inner

cable must be quite free and not binding due to frayed wire or

other causes.

To adjus t the clutch springs take out the oil level

and filler plug and turn the engine gently until one of the three nuts can

be seen through the hole, then with a forked

screwdriver screw in the nut very s lightly ; say a quarter to half a turn. Revolve the engine again until another nut shows

and repeat the operation and again for the third nut, but great care must be taken to ens ur e that each nu t is adju sted

exactly the same amo un t, o therw is e th e p lates w ill b e d isto rted and clutch d rag liab le to occu r.

Clutch slip can sometimes be detected by means of the kick-s tarter, for the s lip can be felt if the pedal

is depressed and the engine fails to turn over. It can also be detected when climbing hills under load by high

revving of the engine with loss of pulling power.

Because either clutch slip or clutch drag (failure to free the drive completely) is occurring, do not jump

to the conclusion that the clutch springs require adjustment. Instead make sure that the clutch cable itself is

quite free in the outer casing and that it is not damaged in any way.

Checking Oil Level in Primary Drive.

This is done by leaning the machine over slightly towards the left hand side, when, if the level is

correct, oil will start to run out of the filler plug hole. If the level is low then oil should be added up to the

bottom edge of the hole and the plug replaced. For the correct grade of oil refer to the oil recom mendation

chart in your instruction book.

Fig. 22. Clutch control adjustment.

Summary of Contents for TW2

Page 1: ......

Page 55: ...SERVICE SHEET No 1050 contd Wiring Diagram 6 Volt Model...

Page 57: ......

Page 58: ...i SERVICE SHEET No 1050 contd...

Page 61: ......

Page 66: ......

Page 73: ......

Page 74: ......

Page 75: ......