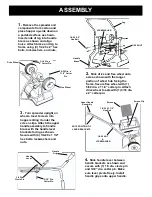

ASSEMBLY

1.

Remove the spreader and

components from carton and

place hopper up-side down on

a padded surface as shown.

Insert ends of leg into handle

brace as shown and align

holes. Attach brace and leg to

frame using (4) 1/4-20 x 2” hex

bolts, lockwashers, and nuts.

3.

Turn spreader upright on

wheels. Insert screen into

hopper sliding it under the

screen clips. Attach the upper

handle assembly to handle

brace with the handle lever

brackets facing as shown.

Secure with (4) 1/4-20 x 1 1/2”

hex bolts, lockwashers and

nuts.

2.

Slide drive and free wheel onto

axle as shown with the longer

portion of wheel hub facing the

frame. Secure free wheel with (1)

5/32 dia. x 1 1/4” cotter pin. Attach

drive wheel to axle with (1) 3/16 dia.

x 2” cotter pin.

5/32 Dia. x

1 1/4” Cotter

Pin

3/16 Dia. x

2” Cotter Pin

NOTE POSITION OF

LEVER BRACKETS

Drive Wheel

Free Wheel

Handle

Brace

Leg

1/4-20 X 2”

Hex Bolt

1/4-20 NUT

Upper Handle

Assembly

Screen

Screen Clip

1/4-20 X 1 1/2”

Hex Bolt

1/4-20 NUT

&

LOCKWASHER

LOCKWASHER

4.

Slide handle lever between

handle brackets as shown and

secure with (1) 1/4 dia. clevis pin

and 3/32” dia. cotter pin. Make

sure lever pivots freely. Install

handle grips onto upper handle.

1/4 Dia.

Clevis Pin

3/32” Dia.

Cotter Pin

Handle

Lever

Handle

Grip

Summary of Contents for 30 +

Page 1: ...OWNER S MANUAL...