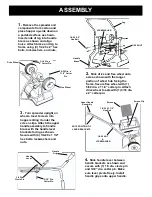

PATTERN ADJUSTMENT

Normal spreading of materials

requires no adjustment (factory

setting “A”) unless stated on the

package. In those cases where the

spread pattern has shifted, the

pattern can be adjusted left and

right by loosening the two knobs on

the discharge chute and moving the

chute closer or farther away from

the impeller. Settings of “A, B, and

C” are provided as reference.

Knob

Discharge

Chute

Impeller

Knob

Discharge Chute

Settings

HOW TO DETERMINE SPREADER

SETTINGS AND SPREAD WIDTH

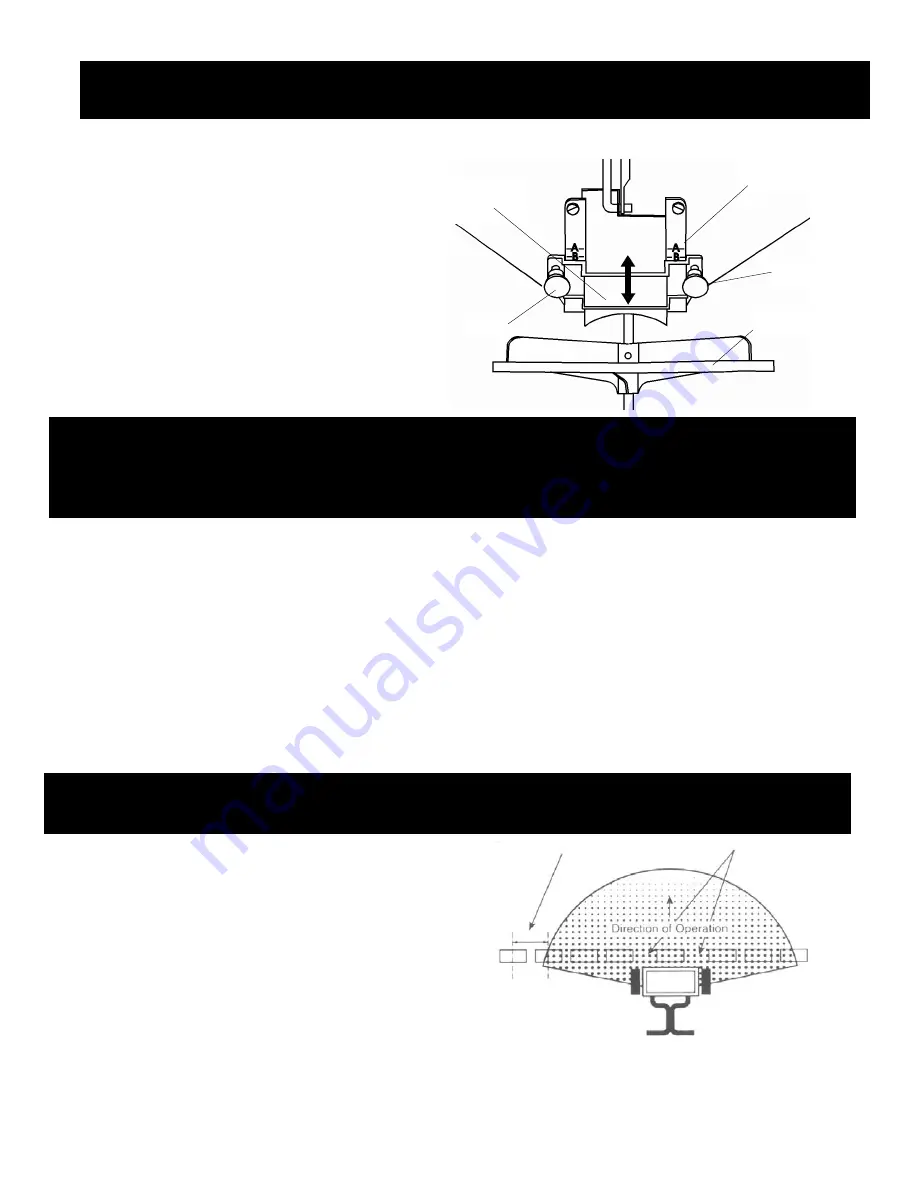

EFFECTIVE PATTERN WIDTH

A simple visual pattern test can be made by

operating spreader over a non-turf area and

evaluating the pattern. A more accurate method

is to place a row of common, disposable, alu-

minun cake tins approximately 30 cm on

centres. Set the rate plate at a middle setting and

make 3 or 4 passes in the same direction as shown.

Pour the material collected from each

pan into individual bottles of the same size. Set

them side by side in order, and visually inspect

their volume. If the pattern is not centered

(example: volume in bottle #2 left not equal to

bottle #2 right) adjust the pattern control as

described in the

“PATTERN ADJUSTMENT”

section.

Once the pattern is uniform, the effective pattern

width can be determined. The effective pattern

width is the distance out from the spreader to a

point where the amount of material is 1/2 the

average amount in the center pans. This dis-

tance is multiplied by 2 to achieve the total

effective pattern width.

Space 1’-0” on Centres

Space for Wheel Track

Two major factors should be considered when determining correct spreader settings of any

product:

1. The product application rate, or the amount of material applied per 500 square meters.

2. The effective pattern width, or the actual width in which the material is applied. Label settings are a

guide and can be effected by numerous factors.

The Trojan HVO is factory calibrated. However, calibration should be checked occasionally to assure

optimum performance.

For accurate calibration Sherriff Amenity recommends the use of the Prizelawn® calibrator for the

Trojan HVO, Trojan 30+, and the Trojan Tow. For all other spreaders standard calibration procedures

should be followed. Visit www.sherriff-amenity.com for further

information.

Summary of Contents for 30 +

Page 1: ...OWNER S MANUAL...