Models: 02-7815C0110, 02A7815C0110, 02A7848C0120

10 Ton (9.07 Metric) Two Stage Jack with Air Pump

07/2021 | Rev. 06

Page | 3

5.0

OPERATION

The user should be familiar with the following statements prior to using the jack.

CAUTION!

1. NEVER put hands between aircraft and jack pad. Aircraft struts may hang up and allow aircraft to

suddenly drop.

2. NEVER align jack under aircraft by pounding on jack legs. Dented legs may lead to jack collapse.

3. ALWAYS lower ram locking nut(s) as aircraft is raised. Be sure ram nut(s) is seated fully after jacking.

4. ALWAYS raise and lower jacks simultaneously so that aircraft remains level.

5. ALWAYS use a tail or nose stand for additional stability.

WARNING!

When collapsing rams by hand miss-staging may occur and cause pinch points. To collapse ram, add a

minimum 50 lb load to the mechanical extension. Keep hands and fingers clear of locking nuts. Failure to

adhere to this safety instruction can cause injury.

5.1

JACK INSTRUCTIONS

To Raise Aircraft:

1. Place jack on a hard, level surface.

2. Raise mechanical extension as close to aircraft jack pad as possible.

3. Close pump release valve and operate pump.

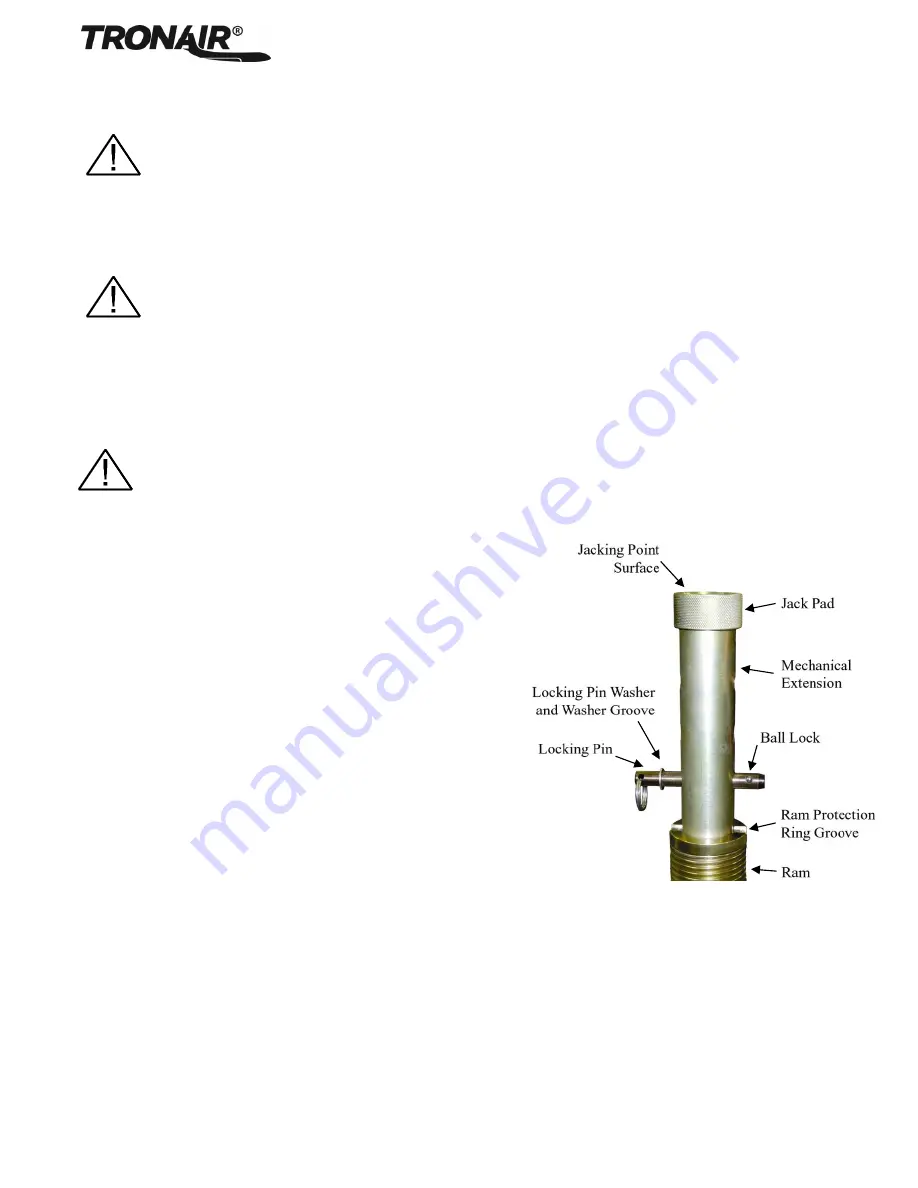

WARNING!

The locking pin MUST be placed in the ram protection ring groove and fully through the mechanical

extension.

The locking pin washer and ball lock MUST be placed outside the ram protection ring.

Visually inspect the jack prior to every use.

Do not place extra locking pins in any other hole on

the mechanical extension.

Insure mating surfaces to jack point are free of

debris and damage.

Under no conditions should the locking pin washer

or washer groove be inside the ram protection ring

groove.

Under no conditions should the lock

ing pin’s ball

lock be inside the ram protection ring groove.

Never use the jack if the ram protection ring is not

installed.

Never use the locking pin without a locking pin

washer.

Never use a locking pin that has been damaged.

Never use a ram protection ring that has been

damaged or deformed.

Replace ram protection ring if it does not have a

radius groove for the locking pin.

Load test jacks annually.

Only order replacement parts from Tronair.

Failure to comply could result in premature failure

below certified weight and could cause serious injury including death.

Summary of Contents for 02-7815C0110

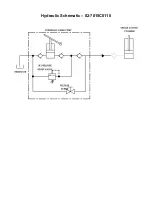

Page 17: ...APPENDIX I Hydraulic Schematic...

Page 18: ......

Page 19: ...Hydraulic Schematic 02 7815C0110...

Page 20: ...Hydraulic Schematic 02A7815C0110 02A7848C0120...

Page 21: ...APPENDIX II Air Pump Manufacturer Data...

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ...APPENDIX III Safety Data Sheet MIL PRF 5606 Hydraulic Fluid...

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ...APPENDIX IV Declaration of Conformity...

Page 64: ......

Page 66: ......

Page 67: ...APPENDIX V Maintenance Schedule...

Page 68: ......

Page 69: ......