Models: 02-7815C0110, 02A7815C0110, 02A7848C0120

10 Ton (9.07 Metric) Two Stage Jack with Air Pump

07/2021 | Rev. 06

Page | 1

This product can not be modified without the written approval of Tronair, Inc. Any modifications done without written approval

voids all warranties and releases Tronair, Inc., it suppliers, distributors, employees, or financial institutions from any liability

from consequences that may occur. Only Tronair OEM replacement parts shall be used.

1.0

PRODUCT INFORMATION

1.1

DESCRIPTION

10 Ton Two Stage Tripod Jack

1.2

MODEL & SERIAL NUMBER

Reference nameplate on unit

1.3

MANUFACTURER

TRONAIR

, Inc.

Telephone: (419) 866-6301 or 800-426-6301

1 Air Cargo Pkwy East

Fax:

(419) 867-0634

Swanton, Ohio 43558 USA

E-mail:

sales@tronair.com

Website:

www.tronair.com

1.4

USAGE

The device is intended to lift an aircraft by its fuselage and/or main wing with other hydraulic jacks arranged by position and

quantity to provide proper balance, and in conjunction with the correct jack pad, whose maximum load on any one jack does

not exceed the rated capacity of the jack.

The jacks are not intended for metal forming, metal working, or any purpose other than that stated above.

1.5

SPECIFICATIONS

Capacity ........................................................ 20,000 lbs (9.07 metric ton)

Closed Height ................................................ 27.6 in (70 cm)

Mechanical Extension ................................... 12 in (30.5 cm)

Hydraulic Extension....................................... 33 in (83.8 cm)

Fully Extended .............................................. 72.5 in (184.2 cm)

Weight

02-7815C0110 ....................................... 271 lbs (123 kg)

02A7815C0110, 02A7847C0120 ........... 286 lbs (130 kg)

2.0

SAFETY INFORMATION

2.1

USAGE AND SAFETY INFORMATION

To insure safe operations please read the following statements and understand their meaning. Also refer to your equipment

manufacturer’s manual for other important safety information. This manual contains safety precautions which are explained

below. Please read carefully.

WARNING!

— Warning is used to indicate the presence of a hazard that

can cause severe personal injury,

death, or substantial property damage

if the warning notice is ignored.

CAUTION!

— Caution is used to indicate the presence of a hazard that

will or can cause minor personal injury

or property damage

if the caution notice is ignored.

2.2

WARNING AND DANGER SIGNS

See labels on unit.

WARNING!

The ram locknuts are user operated safety devices. Failure to utilize these locknuts may result in personal

injury or death.

Summary of Contents for 02-7815C0110

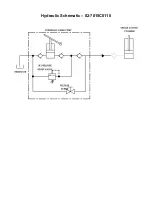

Page 17: ...APPENDIX I Hydraulic Schematic...

Page 18: ......

Page 19: ...Hydraulic Schematic 02 7815C0110...

Page 20: ...Hydraulic Schematic 02A7815C0110 02A7848C0120...

Page 21: ...APPENDIX II Air Pump Manufacturer Data...

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ...APPENDIX III Safety Data Sheet MIL PRF 5606 Hydraulic Fluid...

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ...APPENDIX IV Declaration of Conformity...

Page 64: ......

Page 66: ......

Page 67: ...APPENDIX V Maintenance Schedule...

Page 68: ......

Page 69: ......