Models: 02-7815C0110, 02A7815C0110, 02A7848C0120

10 Ton (9.07 Metric) Two Stage Jack with Air Pump

07/2021 | Rev. 06

Page | 2

2.3

SAFETY GUIDELINES

CAUTION!

Do not place hands on top of jack near ram locknuts while lowering jack.

Pinch points exist between top of jack and threads on ram.

Never put hands between the aircraft and the jack pad; as after aircraft has been lowered, struts may

have hung up.

Never align jack under aircraft by pounding on jack legs. Dented legs may lead to jack collapse.

Always lower ram locking nut(s) after jack is under load. Be sure ram nut(s) is seated fully after

jacking.

Always raise and lower jacks simultaneously so that aircraft remains level.

Always use a tail or nose stand, as applicable, for additional stability.

WARNING!

The ram locknuts are user operated safety devices.

Failure to utilize these locknuts may result in personal injury or death.

2.4

CONDITIONS FOR SAFE USE

Use in a clean dry environment on a level surface.

Operate between -20

C and 50

C/-4

F and 122

F.

3.0

ASSEMBLY INSTRUCTIONS

3.1

GENERAL INFORMATION

This product should be assembled and/or repaired using good workmanship practices and proper tools. Bolts and elastic

stopnuts should be tightened to a torque not to exceed industry standards for Grade '5' bolts. The 3/8-24 bolts should be

tightened to 35 ft-lbs (47.5 N-m).

All replacement parts must be the same as or equal to the original parts supplied.

3.2

PRE-USE CHECKS

Refer to the Parts Lists and Illustrations to identify and ensure that all parts are present.

Generally check over unit to assure the tightness of all nuts, bolts and fittings.

With rams completely collapsed, check hydraulic fluid level: correct level is three-quarter inch (¾"/1.9 cm) below vent, with

the hydraulic ram fully retracted. Replenish with MIL-PRF-5606 fluid as required.

4.0

TRAINING

4.1

TRAINING REQUIREMENTS

The employer of the operator is responsible for providing a training program sufficient for the safe operation of the unit.

4.2

TRAINING PROGRAM

The employer provided operator training program should cover safety procedures concerning use of the unit in and around the

intended aircraft at the intended aircraft servicing location.

4.3

OPERATOR TRAINING

The operator training should provide the required training for safe operation of the unit.

NOTE: Maintenance and Trouble Shooting are to be performed by a skilled and trained technician.

Summary of Contents for 02-7815C0110

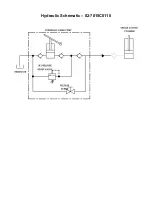

Page 17: ...APPENDIX I Hydraulic Schematic...

Page 18: ......

Page 19: ...Hydraulic Schematic 02 7815C0110...

Page 20: ...Hydraulic Schematic 02A7815C0110 02A7848C0120...

Page 21: ...APPENDIX II Air Pump Manufacturer Data...

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ...APPENDIX III Safety Data Sheet MIL PRF 5606 Hydraulic Fluid...

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ...APPENDIX IV Declaration of Conformity...

Page 64: ......

Page 66: ......

Page 67: ...APPENDIX V Maintenance Schedule...

Page 68: ......

Page 69: ......