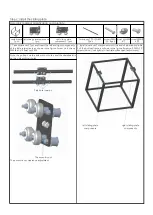

Aluminum4

switch base

1pcs

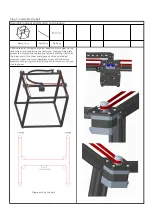

2. Put the switch assembly into 2 screws PM4*9 according to the

position shown, and screw the on-board nut M4

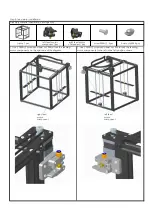

4. Take 1 screw PM3* 45,1 plastic nut M3, screw in according to

the position shown, and pass through the screw tooth hole of

horizontal plate M3.After adjusting the hot bed and screw PM3*45

to the appropriate height, tighten the plastic nut.

Assembly material specification and quantity:

Step 14: limit switch assembly

boat nutsM4

2pcs

screw

PM4*9 2pcs

plastic

nutsM3

1pcs

Switch(incl

wiring) 2pcs

screwPM3*4

5 1pcs

mainframe

1pcs

Note: the screw's torque is small, not too hard.

screwPB2*1

0 4pcs

1. Take 1 piece of switch seat and 2 pieces of switch, and insert 2

screws PB2*10 into it respectively according to the position shown

in the picture, and lock the screws.

3. Fix the switch assembly in the aluminum profile groove with

boat nut, as shown in the figure. The edge of the switch seat is

aligned with the end face of aluminum profile 4, and lock the 2

screws PM4*9, as shown in the figure.

Summary of Contents for X5S 2E

Page 16: ...Wiring diagram of main board ...