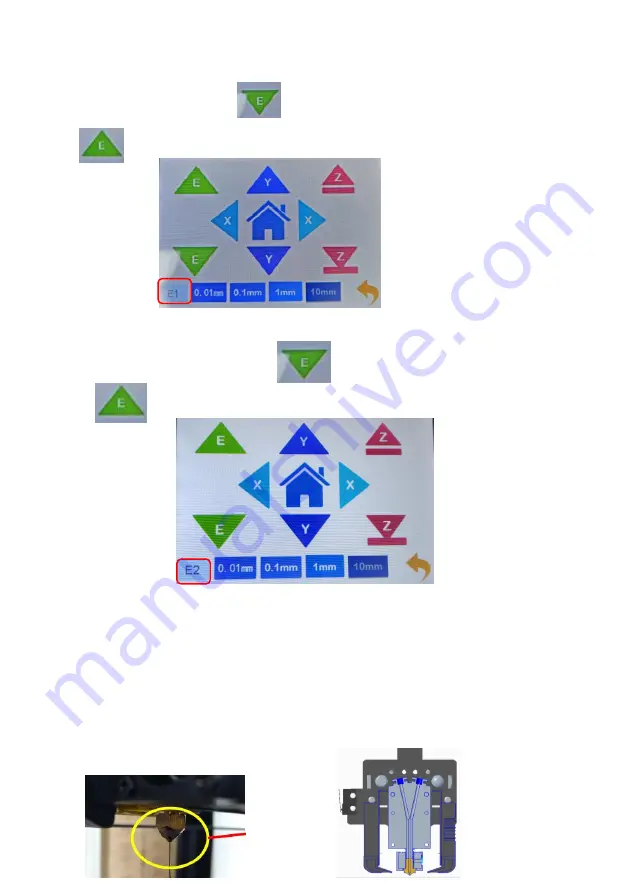

Precautions for double extrusion printing operation:

Enter the manual menu, switch to E1, and set the moving length to 10 mm.

Click to enter consumables Nozzle with consumable extrusion

,

Click

return , the return length is 43mm.

Click E1 in the lower left corner to switch to E2, and the moving length is set to

10 mm. Click to enter consumables

Nozzle with consumable extrusion

,

Clickreturn , the return length is 43mm.

After the above operations are completed, switch back to E1 and feed to the

nozzle again to discharge consumables

Note: the heating temperature of the PLA is 210

±

5 degree and

setting filaments return. When setting other kind of filaments, the

temperature should little higher, to avoid the molten part of

filaments its too big when it return, As a result, the filaments head is

too big for feeding.

19

Summary of Contents for X5SA-400-2E

Page 1: ...X5SA 2E Installation Manual ...

Page 21: ...17 5 Interface operation and printing ...

Page 26: ...2 How to use slice software Type setting follow the steps below to complete the setting 22 ...

Page 31: ......

Page 32: ......