Tel/Fax: 0755-82734836

www.dh-robotics.com

14

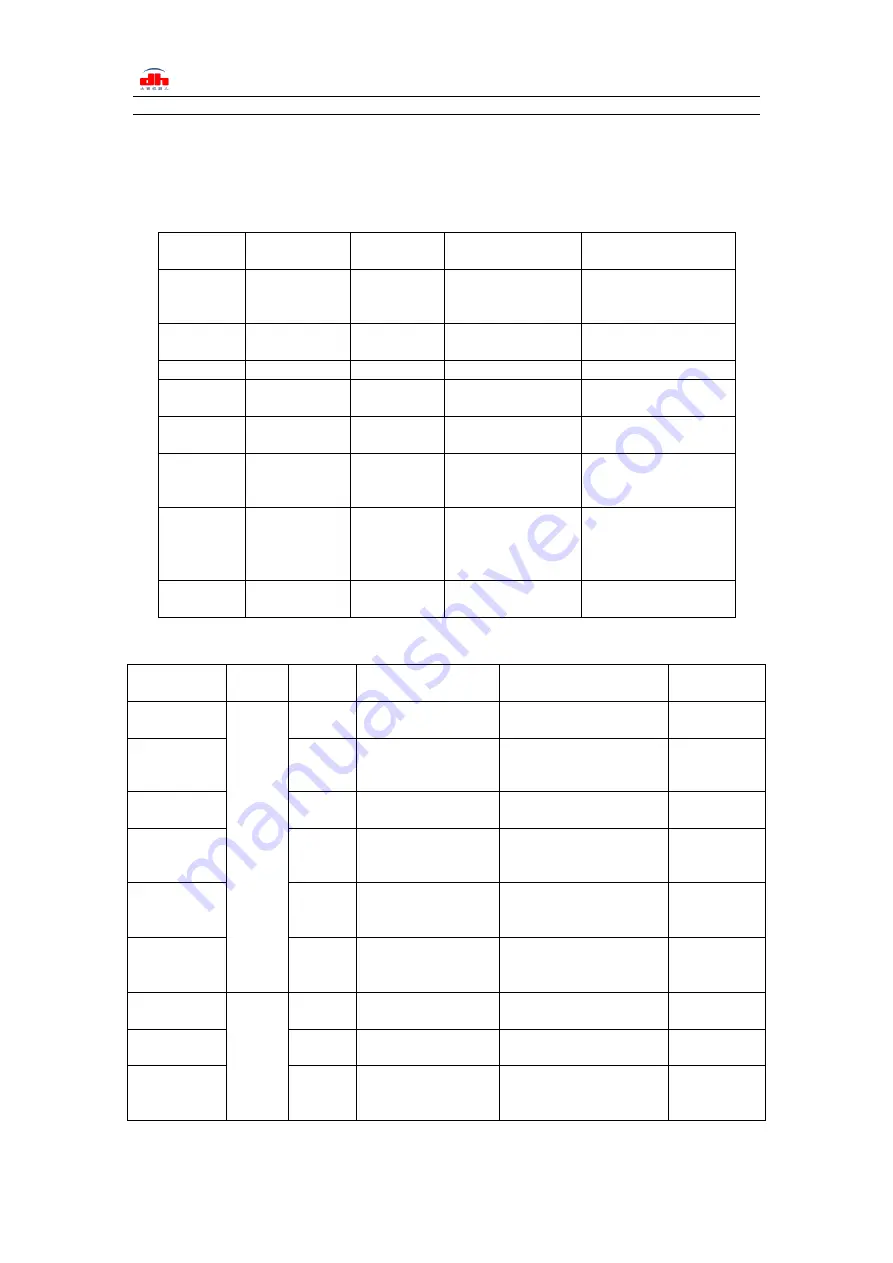

Basic control registers

: initialization, force setting, reference position, speed, and some

states.

Configuration registers

: gripper’s parameter configuration. Includes Modbus

communication parameters and I/O parameters.

Table 2.2 Basic Control register map

Function

address

(hexadecimal)

Description

Write

Read

Initialization

256

(

0x0100

)

Initialize the

gripper

0x01

:

initialization

;

0xA5:

Fully initialization

Current setting

Force

257

(0x0101)

Gripper’s

force

20-100 (%)

Closing-force

currently set

-

-

-

-

-

Position

259

(

0x0103

)

Position

0-1000 (

‰

)

Reference position

currently set

Speed

260

(

0x0104

)

Speed

1-100 (%)

Speed

currently set

Initialization

state

512

(

0x0200

)

Initialization

state of the

gripper

Read Only

0

:

Not initialized

;

1

:

Initialized

Gripper state

513

(

0x0201

)

Gripper state

Read Only

0

:

In motion;

1

:

Reach position

;

2 Object caught

;

3

:

Object dropped

Position

514

(

0x0202

)

gripper

position

Read Only

Current real-time

position

Table 2.3 Configuration register map

Function

High

byte

Low

bytes

Description

Write

Read

Save

Parameter

0x03

0x00

Save all the parameters

0

:

default

,

1

:

Write all

parameters to save

0

Initialization

direction

0x01

Configure

initialization direction

0: Open

,

1:Close

(default: 0

)

Current setting

Slave Address

0x02

Configure gripper

Modbus address

0-255 (default: 1

)

Current setting

Baud Rate

0x03

Configure gripper

Modbus Baud rate

0-5

:

115200

,

57600

,

38400

,

19200

,

9600

,

4800

(

default :0

)

Current setting

Stop Bits

0x04

Configure gripper

Modbus stop bits

0

:

1 stop bit

;

1

:

2 stop bits

(

default: 0

)

Current setting

Parity

0x05

Configure gripper

Modbus Parity

0: None parity;

1: Odd parity;

2: Even parity (default: 0)

Current setting

I/O Parameters

Test

0x04

0x00

Test I/O parameters

1

;

2

;

3

;

4

Current setting

I/O Mode

Switch

0x02

I/O control switch

0

:

OFF

,

1

:

ON

Current setting

I/O Parameter

Configuration

0x05-

0x10

Four groups of I/O

parameters

position 1

,

force 1

,

speed

1 to position 4

,

force 4

,

speed 4

Current setting