EN

10

Operating manual – 3-in-1 multi-function sander PMSS 10-200

ü

Use tools suitable for the intended task.

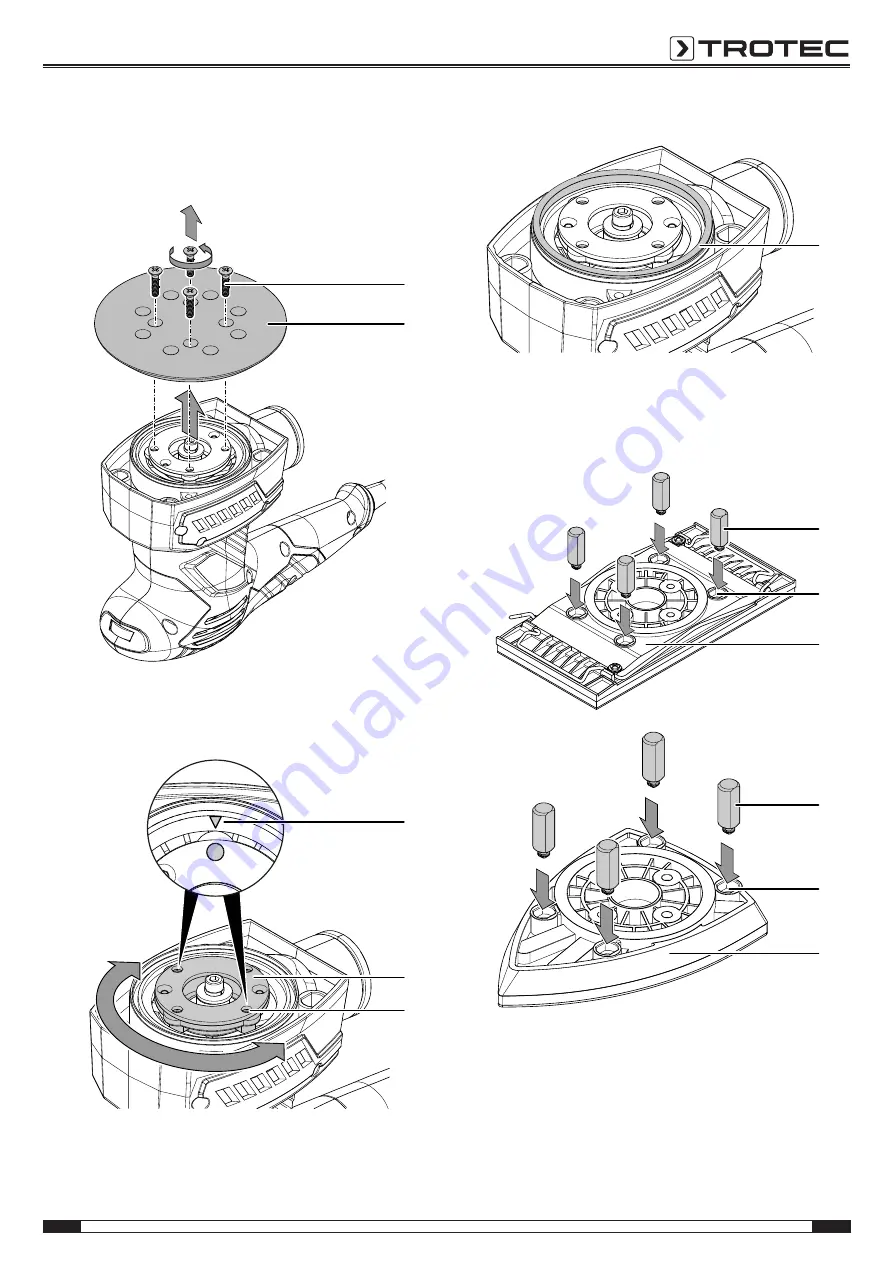

1. Loosen the four screws (9) at the sanding plate (3).

ð

The sanding plate is now loosened.

2. Remove the sanding plate (3) from the device.

9

3

3. Adjust the flange (16) for the selected sanding plate. The

threaded holes (17) for the screws must be aligned with

the marks (18) on the device.

16

17

18

4. Check the felt ring (21) for correct fit.

21

5. When mounting the orbital sanding plate (6) or the delta

sanding plate (14), insert the four rubber pins (10) into the

sanding plate so that the latching noses sit in the

recesses (19).

10

19

6

14

19

10

6. Place the orbital sanding plate (6) or delta sanding

plate (14) onto the flange (16). When mounting the orbital

sanding plate, the arrow (20) must point to the front. When

mounting the delta sanding plate, the tip must point to the

front.

7. Pay attention that the rubber pins (10) are positioned in the

recesses (19) in the device. The rubber pins ensure that

the sanding plate is fixed in position.