16

EN

cordless belt sander PBSS 10-20V

Operation

Tips and notes on handling the belt sander

General information:

•

Only use abrasive belts which are approved for the device

used.

•

Before every application, make sure that you have selected

the correct abrasive belt for the intended use. A coarse grit

is suited for rough grinding, a fine grain size, on the other

hand, is more appropriate for fine and finish grinding.

•

Do not process wood and metal using the same abrasive

belt.

•

Only use intact, flawless abrasive belts. Damaged abrasive

belts could tear and cause damage to the workpiece.

Exchange abrasive belts in due time.

•

Make sure that the abrasive belt does not grind into the

housing.

•

Clamp the workpiece unless it is firmly and safely

positioned by its own weight.

•

Do not overload the device so that it comes to a standstill.

•

Keep the venting slots clear to prevent the motor from

overheating.

•

Only store abrasive belts in a suspended position, as they

are damaged by kinks and the likes.

Sanding:

•

Belt speed and grain size of the abrasive belt define the

removal rate and the surface finish.

•

For grinding off untreated wooden surfaces move the

device in a straight line along with the grain. That way you

can prevent transverse sanding marks. For sanding other

surfaces move the device in ovals. Always sand in parallel

to the grinding path ensuring an appropriate overlap.

•

Do not apply excessive contact pressure. The device's own

weight achieves a sufficient grinding performance

resulting in smoother workpieces surfaces. Increased

contact pressure leads to a greater wear of the device and

the abrasive belt.

•

If the material's surface is untreated, start grinding with

coarse or medium grain size and finish off with a fine grit.

•

Best use a coarse grain size (40 or 60 grit) for removing

paint and for rough grinding particularly raw wood. For

surface-grinding undressed or sawn timber use abrasive

belts of medium grit (grain size 80, 100 or 120). Use a fine

grit (grain size 180, 240 or 320) to smoothen and fine-

grind timber and surfaces coated with old paint as well as

for dry sanding untreated wooden surfaces.

•

Use a dust extraction system when grinding off residual

paint. Paint residues might smelt and then smudge both

workpiece and abrasive belt.

•

Switch the device on before applying it to the workpiece.

Once the grinding process is concluded, lift the device off

the workpiece before you switch it off.

•

Do not attempt to slow down the petering out abrasive belt

by pressing against it.

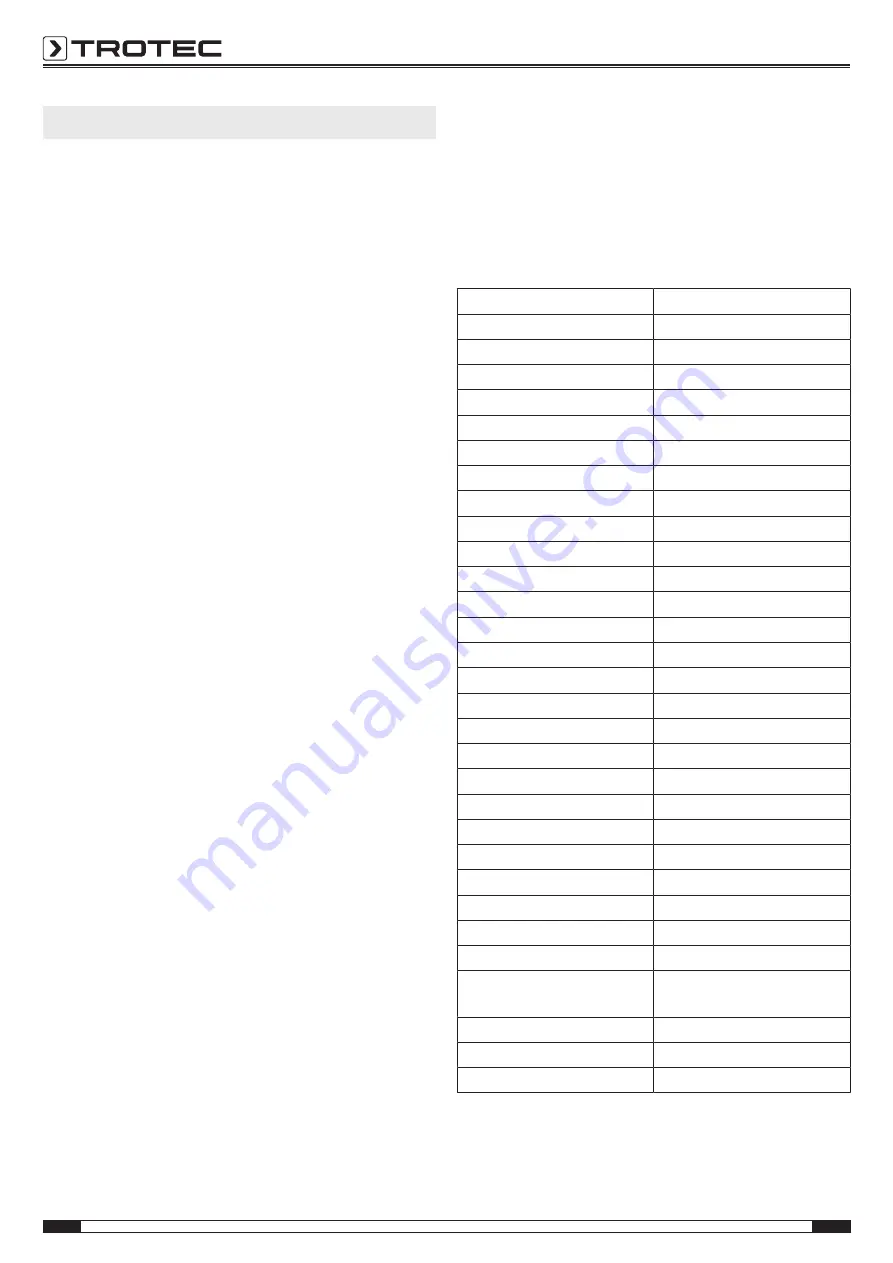

The non-binding values listed in the table below shall serve as a

point of reference for selecting the right abrasive belt and the

proper setting for the task at hand:

Material / field of work

Softwood

coarse sanding

grain size: 60

fine sanding

grain size: 240

belt speed selection

high (5 – 6)

Material / field of work

Hardwood

coarse sanding

grain size: 60

fine sanding

grain size: 180

belt speed selection

high (5 – 6)

Material / field of work

Chipboards

coarse sanding

grain size: 60

fine sanding

grain size: 150

belt speed selection

high (5 – 6)

Material / field of work

Removing paint / varnish

coarse sanding

grain size: 60

belt speed selection

high (5 – 6)

Material / field of work

Sanding down varnishes

coarse sanding

grain size: 150

fine sanding

grain size: 320

belt speed selection

low (1 – 2)

Material / field of work

Derusting steel

coarse sanding

grain size: 40

fine sanding

grain size: 120

belt speed selection

medium / high (3 – 4)

Material / field of work

Plastics

coarse sanding

grain size: 120

fine sanding

grain size: 240

belt speed selection

low / medium (2 – 3)

Material / field of work

Non-ferrous metals (e.g.

aluminium)

coarse sanding

grain size: 80

fine sanding

grain size: 150

belt speed selection

medium / high (3 – 4)