5.5 Supporting construction – solid ceiling slabs

5.5.1 Mortar-based installation

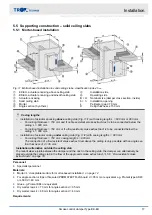

Fig. 11: Mortar-based installation in solid ceiling slabs, classification index: h

ow

①

EK-EU, actuator encasing above ceiling slab

②

EK-EU, actuator encasing underneath ceiling slab

③

Actuator encasing

④

Solid ceiling slab

⑤

Mortar

⑥

Angle section (by others)

Ⓐ

Installation side

Ⓑ

Operating side

B × H

Nominal size (damper cross section, inside)

b × h

Installation opening

s

Perimeter gap

≤

70 mm

D

Ceilig thickness

≥

150 mm

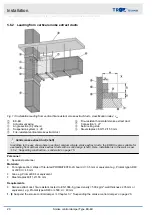

Casing lengths

–

Installation of actuator encasing above ceiling slab (Fig. 11/1) with casing length L = 600 mm or 800 mm

–

For ceiling thickness = 150 mm and if no fire-resistant smoke extract duct is to be connected below the

ceiling: L = 600 mm.

–

For ceiling thickness > 150 mm or if a fire-resistant smoke extract duct is to be connected below the

ceiling: L = 800 mm.

–

Installation of actuator casing under ceiling slab (Fig. 11/2) with casing length L = 800 mm

–

For ceiling thickness = 150 mm: casing length L = 800 mm

The connection of a fire-resistant smoke extract duct above the ceiling is only possible with an angle sec-

tion thickness of d = 35 mm.

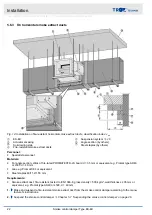

Installation alternative outside the ceiling slab

To prevent sleeve joints between the damper and the duct in the ceiling slab, the damper can alternatively be

placed outside the ceiling slab in the flow of the approved smoke extract duct,

Personnel:

Specialist personnel

Materials:

Mortar

‘Acceptable mortars for mortar-based installation’ on page 12

For angle section: strips of fire-rated PROMATECT®-LS board d = 35 mm or equivalent e.g. Promat type AD40

or L500 d = 40 mm

Glue e.g. Promat K84 or equivalent

Dry wall screws 4

×

70 mm for angle section d = 35 mm

Dry wall screws 4

×

80 mm for angle section d = 40 mm

Requirements:

Installation

Supporting construction – solid ceiling slabs > Mortar-based installation

Smoke control damper Type EK-EU

17