6

Smoke extract duct and

cover grille

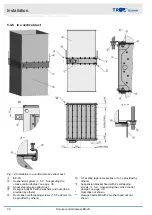

6.1 Smoke extract ducts

Construction of the duct

EK-JS smoke control dampers are allowed to be used

with sheet steel smoke extract ducts for individual sec-

tions that meet the following criteria:

Tested according to DIN EN 1366-9, 120 min. at 600

°C

Pressure level 3 according to DIN EN 1366-9 for

negative pressure down to -1500 Pa and positive

pressure up to +500 Pa

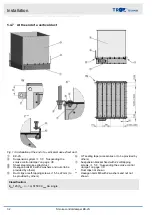

Smoke extract ducts with national general building

inspectorate licences

Smoke extract ducts can also be connected with a

national general building inspectorate licence or a

national general appraisal certificate. If the smoke

control damper is not exposed to mechanical forces,

the functional stability of the smoke control damper is

not affected (connection according to assembly and

operating manual of the smoke control damper). The

sizing of the smoke extract duct used remains the

responsibility of the system installer and the system

owner and must be approved with the respective

national authority.

Sheet steel smoke extract duct

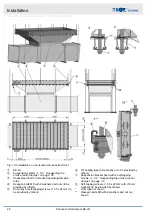

Fig. 18: EK-JS connection to air duct with duct clips

①

EK-JS

②

Linkage cover with recess for duct clips

③

Smoke extract duct

➃

Fixing screws M8 with washers and nut (to be pro-

vided by others)

➄

Duct clips or self-tapping screws

Æ

5.5 x 22 mm (to

be provided by others)

⑥

HT sealing tape (accessories or to be provided by

others)

*

Duct clips not shown

** Hexagon bolts M8 with 2 washers and nut not

shown

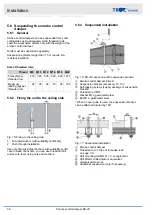

Place the duct clips on the drive side in the recesses of

the linkage cover.

On the other sides, the duct clips can be set freely. Max-

imum distance 200 mm.

Smoke extract duct and cover grille

Smoke extract ducts

Smoke control damper EK-JS

37

Summary of Contents for EK-JS

Page 53: ...Decommissioning removal and disposal Smoke control damper EK JS 53...

Page 54: ...11 Flange dimensional drawing Flange dimensional drawing Smoke control damper EK JS 54...

Page 57: ...Smoke control damper EK JS 57...

Page 58: ...Smoke control damper EK JS 58...

Page 59: ...Smoke control damper EK JS 59...