4-way arrangement with common duct

Direct assembly of 4 fire dampers and connection/

sealing using blanking plates provided by others.

The blanking plates (galvanised steel, min. 1 mm,

approx. 60 mm wide, L = 2

×

W / H + 60 mm) are

positioned on a duct seal and screwed on with self-

tapping screws spaced approx. 150 mm apart.

Mineral wool as filling material

Unless otherwise stated in the installation details, min-

eral wool with a gross density of ≥ 80 kg/m³ and a

melting point of ≥ 1000 °C must be used.

Fire-resistant cladding

When you use installation kit WE, the following mate-

rials are acceptable for the cladding of fire dampers and

ducts:

Promatect® LS35

Promatect® L500

Promatect® AD40

Installation with installation kit ES

Casing length L = 500 mm

The installation kit must be mounted on the fire

damper by others.

Enough clear space is required for installation of the

installation kit.

The installation kit ES is fastened with dry wall

screws

Æ

5.5 mm and brackets, in which case the

dry wall screws must always engage with the stud

frame. The dry wall screws must be long enough so

that the damper can be firmly fastened. The holes of

the fixing points on the B side are made in the fac-

tory.

For installation near the floor or ceiling, professio-

nally shorten the installation kit on one side. Then

use the brackets that were previously on sides B

and fix them in the upper parts of sides H (see

installation details). The holes must be pre-drilled to

Æ

4 mm.

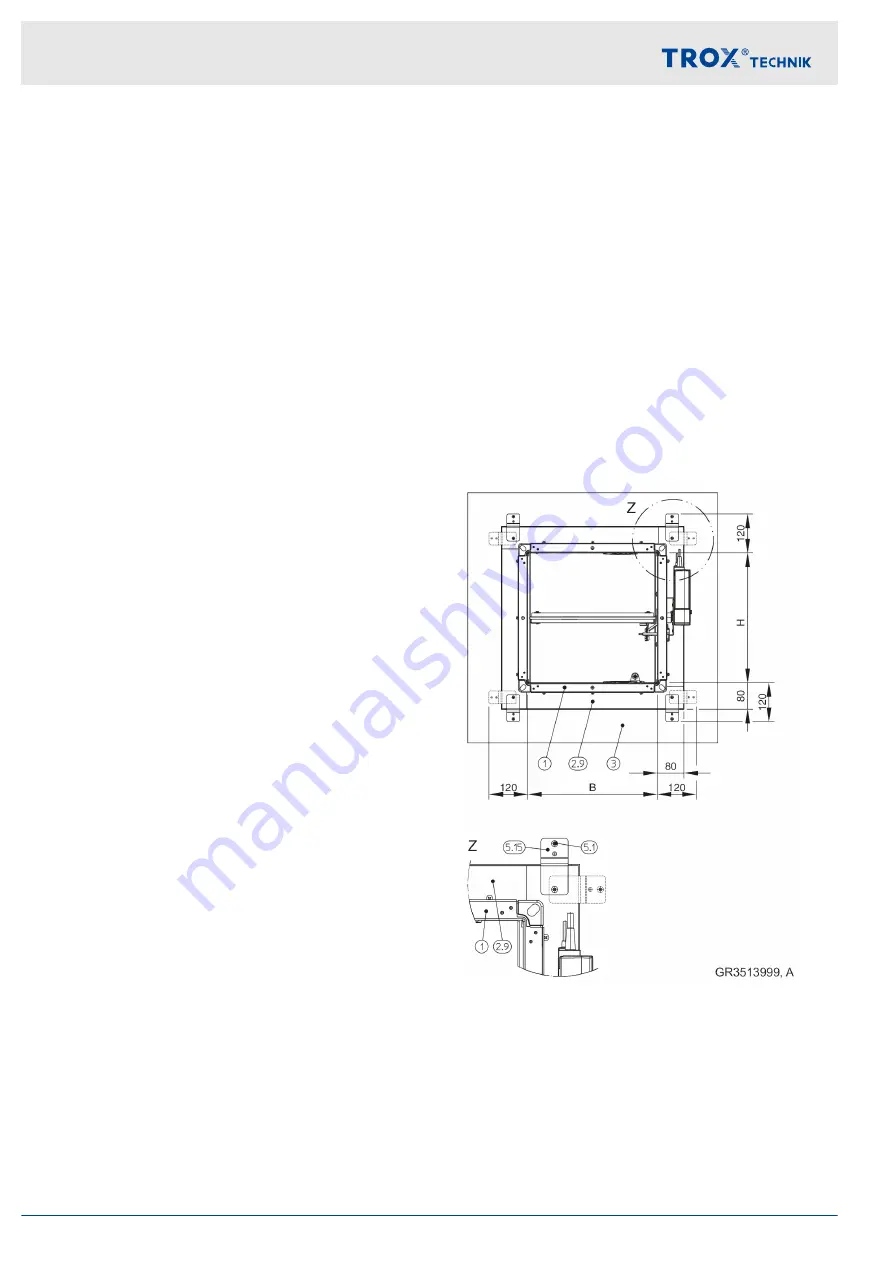

Fig. 16: Installation kit – free space (with normal installa-

tion)

1

FKA2-EU

2.9

Installation kit ES

3

Wall

5.1

Dry wall screw, to be provided by others

5.15 Bracket

Installation

General installation information

Fire damper Type FKA2-EU

32