Solid walls

Solid walls or compartment walls made of, for

example, concrete, aerated concrete, masonry, or

solid gypsum wallboards according to EN 12859

(without open spaces), gross density

≥

350 kg/m³.

Wall thickness W

≥

100 mm, solid gypsum wall-

boards W

≥

80 mm.

Provide each installation opening and core drilled

holes according to the local and structural conditions

and with regard to the dimensions of the fire

damper.

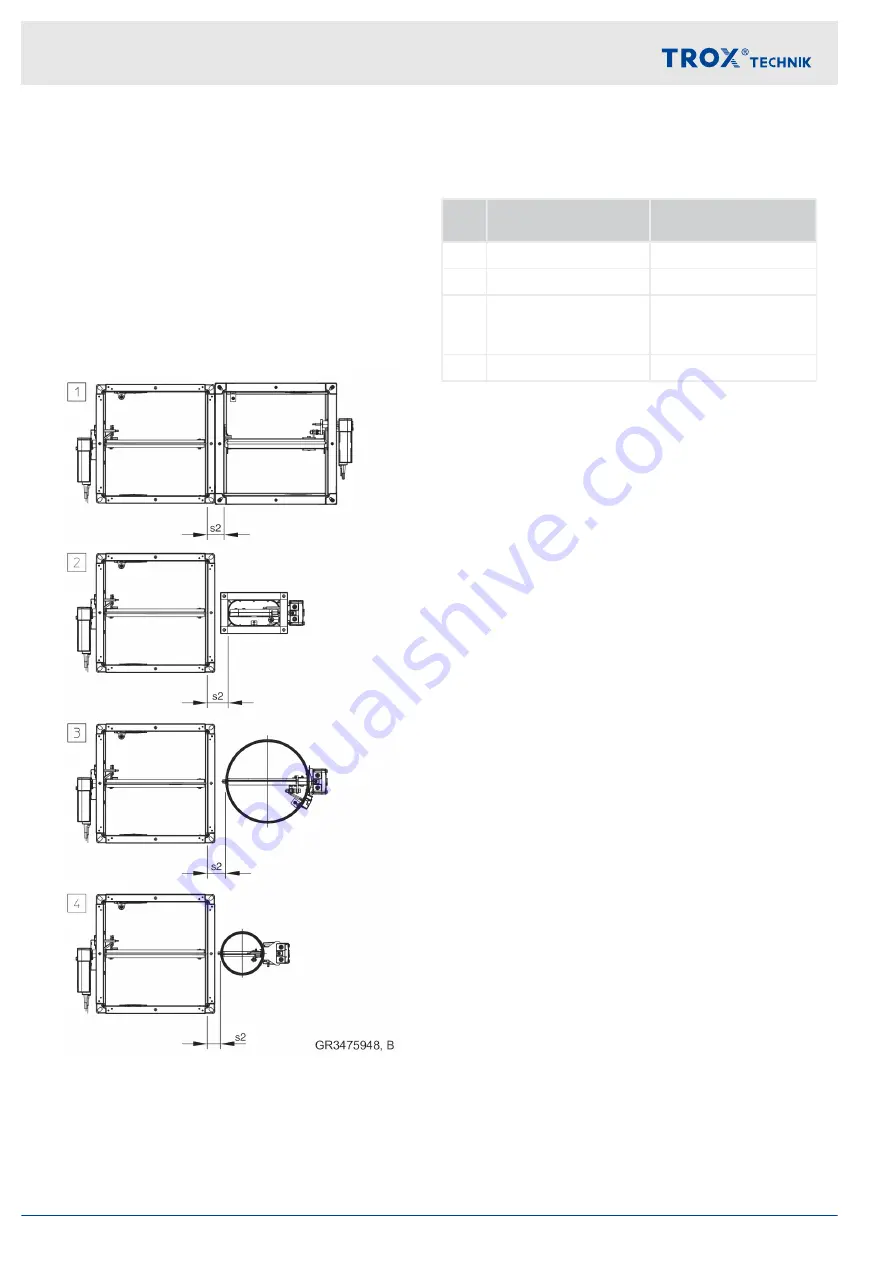

Fig. 21: Distance from the FKA2-EU to other TROX fire

dampers in mortar-based installation

Distance between different TROX fire dampers in

mortar-based installation in solid walls (one installa-

tion opening)

Item

no.

Damper combination

up to EI 90 S

s2 [mm]

1

FKA2-EU – FK-EU

65 – 225

2

FKA2-EU – FKS-EU

80 – 150

3

FKA2-EU – FKR-EU

70 – 120 (80 – 120

with

flange construction)

4

FKA2-EU – FKRS-EU

50 – 225

Lightweight partition walls with metal support struc-

ture

Lightweight partition walls, safety partition walls or

walls to provide radiation protection, with metal sup-

port structure or steel support structure (box sec-

tions), with European classification to EN 13501-2 or

equivalent national classification.

Cladding on both sides made of gypsum bonded or

cement bonded panel materials, fibre-reinforced

gypsum or fire-rated calcium silicate boards.

Wall thickness W

≥

94 mm, for compartment walls

or safety partition walls W

≥

100 mm.

Distance between metal support structures

≤

625 mm; distance between metal support struc-

tures in compartment walls

≤

312.5 mm.

Compartment walls and safety partition walls may

be provided with sheet steel inserts and may require

less space between the metal studs.

Create an installation opening with trimmers (studs

and noggings).

If necessary, provide trim panels and screw-fix them

to the support structure

Additional layers of cladding (if stated in the usability

certificate for the wall) and double stud construc-

tions are approved.

Connect the metal sections near the installation

opening according to the installation details in this

manual.

If reinforcing boards are required, they must be

screwed to the metal support structure at intervals of

approx. 100 mm.

Installation only permitted in non-load-bearing walls

(load-bearing wall constructions on request).

Installation

General installation information

Fire damper Type FKA2-EU

36